Pump & Lubricants

Kennedy Oil Can, 250cc, Metal

Comprising of an enamel finish and a heavy-gauge, seamless metal body, these oil cans are suited for heavy-duty applications. Each can has a positive force feed brass pump and valve and is supplied with both rigid metal and flexible nylon threaded spouts. Finished in a red colour.

Features and Benefits

• Enamel finish provides additional protection against wear and tear

• Heavy gauge construction makes for a robust and resilient product

• Supplied with one metal and one flexible nylon spout for versatility

• Available in a range of sizes to suit your requirements

Typical Applications

• Automotive

• Construction

Features and Benefits

• Enamel finish provides additional protection against wear and tear

• Heavy gauge construction makes for a robust and resilient product

• Supplied with one metal and one flexible nylon spout for versatility

• Available in a range of sizes to suit your requirements

Typical Applications

• Automotive

• Construction

Download

Products Lainnya

Kennedy Hydraulic Nipple, 45°, 1/8"x28 BSP(T), Steel

For use with Kennedy grease guns and all other hydraulic grease equipment.

Kennedy SPH/205, Syphon Pump, 205L, Plastic

Available to suit 25 or 205 litre containers, these syphon pumps are an efficient way of controlling and dispensing a host of fluids. Comprised of a flexible plastic outlet and semi-rigid inlet tubes, the hand pumping units incorporate one-way valves. Suited for use with petrol and diesel as well as with non-corrosive liquids. All tubes can be cut to length and are fitted with a threaded bung. Model SPS/25 has a squeeze action and models SPS/205 and SPH/205 have a plunger-type action.

Features and Benefits

• Tubes can be cut to your desired length to meet your requirements

• Suitable for use with petrol, diesel and all non-corrosive liquids

• Available to suit three sized containers

• Flexible nature allows you to manipulate the pump to your desired position

Typical Applications

• Engineering

• Aquatics

• Automotive

Features and Benefits

• Tubes can be cut to your desired length to meet your requirements

• Suitable for use with petrol, diesel and all non-corrosive liquids

• Available to suit three sized containers

• Flexible nature allows you to manipulate the pump to your desired position

Typical Applications

• Engineering

• Aquatics

• Automotive

Moresco Hydraulic Fluids

Hydraulic fluids are pressure transfer mediums used to transfer the energy stored by way of a hydraulic pump to the hydraulic actuators of cylinders, motors, and other similar devices. To provide precise, accurate, and stable operation of hydraulic equipment, these fluids must have lubricating properties, rust-prevention and corrosion-prevention properties, special temperature and viscosity properties, stability properties, foam suppression properties, and similar properties.

Among these products, HYDOL, our fire resistant hydraulic fluid, is used in hydraulic equipment such as die-cast machines used in the manufacturing of aluminum automotive parts, steel works, and presses. HYDOL protects plant equipment from fires.

HYDOL HAW Series

For hydraulic equipment that handles melted metal such as steel working equipment and die-cast machines, a major fear is the hydraulic fluid catching on fire. To prevent plant fires before they happen, fire resistant hydraulic fluid, which does not catch on fire easily, is used. Among all fire resistant hydraulic fluids, water-glycol type hydraulic fluid exhibits excellent flame resistance as well as having a good balance among all other hydraulic fluid properties.

HAW Red clear liquid : Water-glycol hydraulic fluid with a flame-retardant and high lubricity. Available in a high-pressure area of 14-25MP discharge pressure.

HYDOL AW Series

These products have excellent anti wear properties. A general use type, anti wear type, and high viscosity index type are available. Various viscosity grades are available for each type.

AW-series : Wear resistance hydraulic fluid.

Among these products, HYDOL, our fire resistant hydraulic fluid, is used in hydraulic equipment such as die-cast machines used in the manufacturing of aluminum automotive parts, steel works, and presses. HYDOL protects plant equipment from fires.

HYDOL HAW Series

For hydraulic equipment that handles melted metal such as steel working equipment and die-cast machines, a major fear is the hydraulic fluid catching on fire. To prevent plant fires before they happen, fire resistant hydraulic fluid, which does not catch on fire easily, is used. Among all fire resistant hydraulic fluids, water-glycol type hydraulic fluid exhibits excellent flame resistance as well as having a good balance among all other hydraulic fluid properties.

HAW Red clear liquid : Water-glycol hydraulic fluid with a flame-retardant and high lubricity. Available in a high-pressure area of 14-25MP discharge pressure.

HYDOL AW Series

These products have excellent anti wear properties. A general use type, anti wear type, and high viscosity index type are available. Various viscosity grades are available for each type.

AW-series : Wear resistance hydraulic fluid.

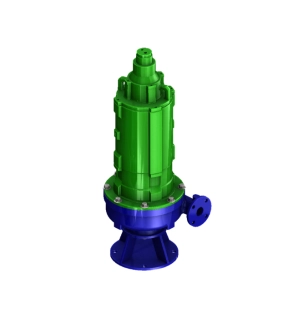

Discflo Submersible Pumps

Our submersible pumps often go to work where centrifugal, progressive cavity, lobe, and chopper pumps have failed. Their unique design and our state-of-the-art technology tackle even the toughest applications with ease.