Pump & Lubricants

Kennedy Hydraulic Nipple, 45°, 1/8"x28 BSP(T), Steel

For use with Kennedy grease guns and all other hydraulic grease equipment.

Download

Products Lainnya

Moresco Metal Working Fluids

Cutting fluids are used when metals or similar materials are cut and made into finished products by machine tools such as lathes, machining centers, and grinding machines. MORESCO is developing cutting fluids that have long service lives, which reduces the amount of waste fluid that is generated and thereby contributes to environmental improvements.

Toolmate Waterbase

BS-33 (Biostatic Types) : Machining of aluminum and steel.

GR-2 (Biostatic Types) : Precision grinding, Efficient grinding of steel, and special metals.

Toolmate Oilbase

NN Series : Inactive oil-based cutting oil. There is no discoloration such as copper · brass etc. We have variety types from low to high viscosity.

NA Series : Active type of oil-based cutting oil. It has great processability for iron based workpieces. We have variety types from low to high viscosity.

Toolmate Waterbase

BS-33 (Biostatic Types) : Machining of aluminum and steel.

GR-2 (Biostatic Types) : Precision grinding, Efficient grinding of steel, and special metals.

Toolmate Oilbase

NN Series : Inactive oil-based cutting oil. There is no discoloration such as copper · brass etc. We have variety types from low to high viscosity.

NA Series : Active type of oil-based cutting oil. It has great processability for iron based workpieces. We have variety types from low to high viscosity.

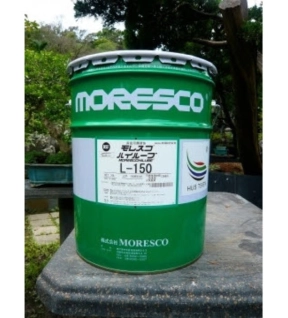

Moresco High Temperature Lubricants

HILUBE

MORESCO-HILUBE, our high temperature lubricating oil, is used in harsh environments as the base oil of greases used with bearings subject to the high temperatures of automotive electrical components and as the lubricating oil used with bearings of machinery such as OA machinery, with bread ovens, and with the drive section of drying furnaces.

L-150 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-320 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-560 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-830 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

MORESCO-HILUBE, our high temperature lubricating oil, is used in harsh environments as the base oil of greases used with bearings subject to the high temperatures of automotive electrical components and as the lubricating oil used with bearings of machinery such as OA machinery, with bread ovens, and with the drive section of drying furnaces.

L-150 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-320 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-560 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-830 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

Kennedy Hydraulic Nipple, 90°, 1/8" BSP(T), Steel

For use with Kennedy grease guns and all other hydraulic grease equipment.

Kennedy Red-Hot-Dip Hot Dip, Bar, Translucent, 1 Pcs

Hot dip protective plastic coating moulds around the component or tool to provide 100% coverage and protect against impact and corrosion.

Features and Benefits

• Hot dip plastic coating moulds itself around the part to provide 100% coverage and protect against corrosion and impacts for up to ten years

• Easy part identity through the translucent coating

• Simple to remove by peeling off

• Once removed, leaves behind a thin oil film to provide short term protection against corrosion

• Removed coatings may be reused saving cost

Notes

• Each single block measures (L)-150mm (H)-50mm (W)-80mm

• Working temperature 130°C to 160°C (for optimum results 140°C to 145°C)

Warnings

• Never directly apply heat to melt the protective dip

• Always use with a suitable melting pot

Features and Benefits

• Hot dip plastic coating moulds itself around the part to provide 100% coverage and protect against corrosion and impacts for up to ten years

• Easy part identity through the translucent coating

• Simple to remove by peeling off

• Once removed, leaves behind a thin oil film to provide short term protection against corrosion

• Removed coatings may be reused saving cost

Notes

• Each single block measures (L)-150mm (H)-50mm (W)-80mm

• Working temperature 130°C to 160°C (for optimum results 140°C to 145°C)

Warnings

• Never directly apply heat to melt the protective dip

• Always use with a suitable melting pot