Pump & Lubricants

Kennedy Red-Hot-Dip Hot Dip, Bar, Translucent, 1 Pcs

Hot dip protective plastic coating moulds around the component or tool to provide 100% coverage and protect against impact and corrosion.

Features and Benefits

• Hot dip plastic coating moulds itself around the part to provide 100% coverage and protect against corrosion and impacts for up to ten years

• Easy part identity through the translucent coating

• Simple to remove by peeling off

• Once removed, leaves behind a thin oil film to provide short term protection against corrosion

• Removed coatings may be reused saving cost

Notes

• Each single block measures (L)-150mm (H)-50mm (W)-80mm

• Working temperature 130°C to 160°C (for optimum results 140°C to 145°C)

Warnings

• Never directly apply heat to melt the protective dip

• Always use with a suitable melting pot

Features and Benefits

• Hot dip plastic coating moulds itself around the part to provide 100% coverage and protect against corrosion and impacts for up to ten years

• Easy part identity through the translucent coating

• Simple to remove by peeling off

• Once removed, leaves behind a thin oil film to provide short term protection against corrosion

• Removed coatings may be reused saving cost

Notes

• Each single block measures (L)-150mm (H)-50mm (W)-80mm

• Working temperature 130°C to 160°C (for optimum results 140°C to 145°C)

Warnings

• Never directly apply heat to melt the protective dip

• Always use with a suitable melting pot

Download

Products Lainnya

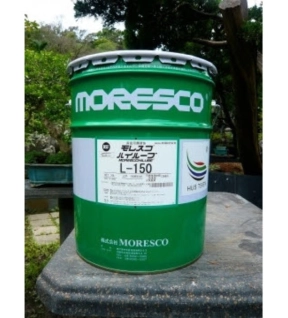

Moresco High Temperature Lubricants

HILUBE

MORESCO-HILUBE, our high temperature lubricating oil, is used in harsh environments as the base oil of greases used with bearings subject to the high temperatures of automotive electrical components and as the lubricating oil used with bearings of machinery such as OA machinery, with bread ovens, and with the drive section of drying furnaces.

L-150 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-320 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-560 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-830 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

MORESCO-HILUBE, our high temperature lubricating oil, is used in harsh environments as the base oil of greases used with bearings subject to the high temperatures of automotive electrical components and as the lubricating oil used with bearings of machinery such as OA machinery, with bread ovens, and with the drive section of drying furnaces.

L-150 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-320 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-560 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-830 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

Kennedy Hydraulic Nipple, Straight, 1/8"x28 BSP(T), Steel

These imperial, straight type hydraulic grease nipples are suited for use with Kennedy® grease guns and all other hydraulic grease equipment. With an all steel construction, the product is resilient and available in three varying sizes.

Features and Benefits

• Available with three varying thread connectors to suit your existing tool

• Manufactured from durable steel to bolster product longevity

• Can be used with grease guns as well as all other hydraulic grease equipment for versatility of use

Typical Applications

• Engineering

• Automotive

Features and Benefits

• Available with three varying thread connectors to suit your existing tool

• Manufactured from durable steel to bolster product longevity

• Can be used with grease guns as well as all other hydraulic grease equipment for versatility of use

Typical Applications

• Engineering

• Automotive

Kennedy Side Lever Grease Gun, 500cc, Bulk/Cartridge/Suction Fill, 6000psi

This side lever grip grease gun is ideal for professionals with its enamel finished steel body and high working pressure of 6000 psi/400 bar. It is suitable for medium/heavy greases.

Features & Benefits

• Enamel finish steel body provides long lasting durability

• Side grip and offset nozzle allows precision on application

• Cartridge, bulk or suction fill allows for flexibility on refills

Features & Benefits

• Enamel finish steel body provides long lasting durability

• Side grip and offset nozzle allows precision on application

• Cartridge, bulk or suction fill allows for flexibility on refills

Discflo Cantilever

Cantilever pumps are ideal for moving abrasive materials and slurries, as only a portion of the pump is located under the fluid. The seals, bearings, bushings, and suction check valves are all outside of the liquid, preventing the material from degrading or interfering with them.

Our cantilever pumps are designed by our engineering team that specializes in handling the toughest pumping jobs. They set the standard for pumping slurries and abrasive materials.

Our cantilever pumps are designed by our engineering team that specializes in handling the toughest pumping jobs. They set the standard for pumping slurries and abrasive materials.