Pump & Lubricants

Kennedy Hydraulic Nipple, 90°, 1/8" BSP(T), Steel

For use with Kennedy grease guns and all other hydraulic grease equipment.

Download

Products Lainnya

Kennedy Line Marker Spray Paint, Red, Aerosol, 750ml

The Kennedy range of line markers are the perfect marking solution ideal for use on car parks, factory/ warehouse floors, playgrounds, sports fields, tennis courts, leisure centres and road surfaces. Its Aerosol delivered formula is suitable for use with stencils or free hand marking.

CFC-free and containing no lead additives, it is safe and convenient to use, capable of marking between 60-100 metres of a 50mm line when used in a standard machine. It is also compatible with most major brand applicators.

Features and Benefits

• Can be used on a variety of surfaces allowing lines to be made in various locations

• One line marker will give between 60-100 metres of a 50mm line when used in a standard machine

• Fully compatible with major brand applicators

• CFC-free formula and no lead additives

• Suitable for stencils, line or free hand marking

• Ideal for use on car parks, factory floors, playgrounds, sports fields, tennis courts and road surfaces

• Available in a range of colours

Typical Applications

• Road Marking

• Leisure Indusrty

• Industrial Floors

Warning

• Flammable- Aerosol

CFC-free and containing no lead additives, it is safe and convenient to use, capable of marking between 60-100 metres of a 50mm line when used in a standard machine. It is also compatible with most major brand applicators.

Features and Benefits

• Can be used on a variety of surfaces allowing lines to be made in various locations

• One line marker will give between 60-100 metres of a 50mm line when used in a standard machine

• Fully compatible with major brand applicators

• CFC-free formula and no lead additives

• Suitable for stencils, line or free hand marking

• Ideal for use on car parks, factory floors, playgrounds, sports fields, tennis courts and road surfaces

• Available in a range of colours

Typical Applications

• Road Marking

• Leisure Indusrty

• Industrial Floors

Warning

• Flammable- Aerosol

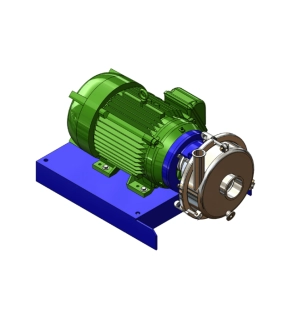

Discflo Sanitary Pumps

Discflo offers two lines of sanitary pumps, the SP Series and MIS Series. Both series meet 3-A sanitary and international hygiene standards and USDA requirements.

They can be supplied in Clean-in-Place or Steam-in-Place versions, and in a variety of metallurgy to meet the user’s requirements.

They can be supplied in Clean-in-Place or Steam-in-Place versions, and in a variety of metallurgy to meet the user’s requirements.

Kennedy Hose, Flexible, 1/8" BSP x 300mm, Nylon

For use with Kennedy grease guns, these flexible nylon hoses are designed to improve access in confined spaces. Varying in length and bore size, each product possesses a 1/8" BSP connecting thread.

Features and Benefits

• Flexible nature makes the products suited for use in confined or awkward areas

• Available in a variety of lengths and bore sizes to suit your needs

• Manufactured from nylon for durability and flexibility

Typical Applications

• Automotive

• Engineering

Features and Benefits

• Flexible nature makes the products suited for use in confined or awkward areas

• Available in a variety of lengths and bore sizes to suit your needs

• Manufactured from nylon for durability and flexibility

Typical Applications

• Automotive

• Engineering

Kennedy Water Container, 20L, HDPE, Compatible with Water

These food-grade plastic water containers from Kennedy® store and dispense large quantities of water. Secured via a collared screw top lid, each container features an on-off tap for easy dispensing and quick shut-off.

The integrated handle allows for easy transport, while the sturdy plastic construction provides reliable upright water storage.

Features and Benefits

• On-off tap for spill-free dispensing

• Moulded integral handle allows for easy transportation

• Manufactured from food-grade plastic for safety and hygiene

• Collared screw top allows for easy refill

• Detachable tap for easy cleaning

• BPA-free construction to avoid hazardous chemicals in drinking water

• Durable construction resists impact for a long service life

• Cap is secured to the bottle with a flexible band to avoid loss

• Available in 10, 15, 20 or 35 litres depending on your needs

Typical Applications

• Domestic

• Warehousing

• Facilities management

• Transport

Standards

• Food-Grade compatible (EU) No. 10/2011

• FDA 21 CFR 177.1520

The integrated handle allows for easy transport, while the sturdy plastic construction provides reliable upright water storage.

Features and Benefits

• On-off tap for spill-free dispensing

• Moulded integral handle allows for easy transportation

• Manufactured from food-grade plastic for safety and hygiene

• Collared screw top allows for easy refill

• Detachable tap for easy cleaning

• BPA-free construction to avoid hazardous chemicals in drinking water

• Durable construction resists impact for a long service life

• Cap is secured to the bottle with a flexible band to avoid loss

• Available in 10, 15, 20 or 35 litres depending on your needs

Typical Applications

• Domestic

• Warehousing

• Facilities management

• Transport

Standards

• Food-Grade compatible (EU) No. 10/2011

• FDA 21 CFR 177.1520