Pump & Lubricants

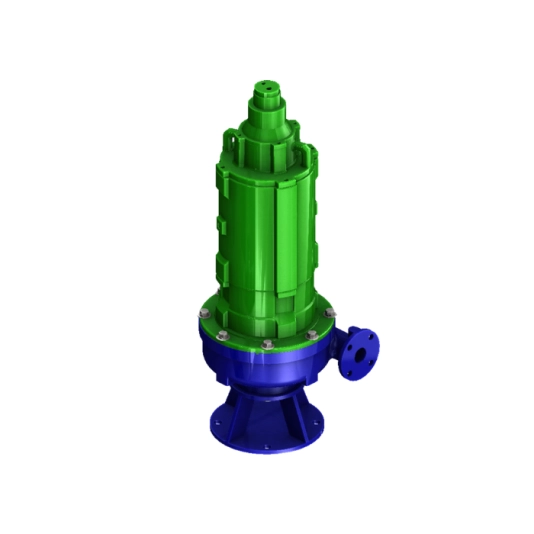

Discflo Submersible Pumps

Our submersible pumps often go to work where centrifugal, progressive cavity, lobe, and chopper pumps have failed. Their unique design and our state-of-the-art technology tackle even the toughest applications with ease.

Download

Produk Lainnya

Kennedy Lever Pump, 0.3L

Suitable for lubricants, diesel and non-corrosive liquids, this lever pump is constructed from a zinc chrome finish steel and is completed with a telescopic suction tube. Suitable for container sizes 60 and 205 litres, the innlet on the pump is 2" BSP and M59 x 5 male thread.

Features and Benefits

• Manufactured from steel for durability

• Zinc chrome finish protects against corrosion and wear and tear

• Can be used with both 60 and 205 litre containers making it a versatile product

• Is compatible with non-corrosive liquids and most lubricants

• Telescopic suction tube allows you to adjust the tube to suit your desired container

Typical Applications

• Automotive

• Engineering

Features and Benefits

• Manufactured from steel for durability

• Zinc chrome finish protects against corrosion and wear and tear

• Can be used with both 60 and 205 litre containers making it a versatile product

• Is compatible with non-corrosive liquids and most lubricants

• Telescopic suction tube allows you to adjust the tube to suit your desired container

Typical Applications

• Automotive

• Engineering

Kennedy Hose, Flexible, 1/8" BSP x 500mm, Nylon

For use with Kennedy grease guns, these flexible nylon hoses are designed to improve access in confined spaces. Varying in length and bore size, each product possesses a 1/8" BSP connecting thread.

Features and Benefits

• Flexible nature makes the products suited for use in confined or awkward areas

• Available in a variety of lengths and bore sizes to suit your needs

• Manufactured from nylon for durability and flexibility

Typical Applications

• Automotive

• Engineering

Features and Benefits

• Flexible nature makes the products suited for use in confined or awkward areas

• Available in a variety of lengths and bore sizes to suit your needs

• Manufactured from nylon for durability and flexibility

Typical Applications

• Automotive

• Engineering

Kennedy Hydraulic Nipple, 45°, M10x1.5, Stee

For use with Kennedy grease guns and all other hydraulic grease equipment.

Kennedy Funnel, 160mm, Polypropylene, Angled Rigid Spout

With an anti-splash rim, removable brass filter, integral handle and either a rigid offset or flexi spout, these polyethylene funnels are ideal for controlled fluid dispensing. Resistant to both oil and chemicals, the products are highly durable and versatile.

Features and Benefits

• Heavy-duty polyethylene construction makes for a resilient product

• Available with either a flexi or offset spout depending on your preference and requirements

• Anti-splash rims minimise the amount of liquid that is spilt when dispensing

• Integrated handle allows you to easily transport and manouevre the product

• Supplied with a brass filter to clear out debris as you pour into the funnel

• Resistant to oils, chemicals and cold weather as well as being shatterproof

Typical Applications

• Workshops

• Domestic

• Automotive

Features and Benefits

• Heavy-duty polyethylene construction makes for a resilient product

• Available with either a flexi or offset spout depending on your preference and requirements

• Anti-splash rims minimise the amount of liquid that is spilt when dispensing

• Integrated handle allows you to easily transport and manouevre the product

• Supplied with a brass filter to clear out debris as you pour into the funnel

• Resistant to oils, chemicals and cold weather as well as being shatterproof

Typical Applications

• Workshops

• Domestic

• Automotive