Pump & Lubricants

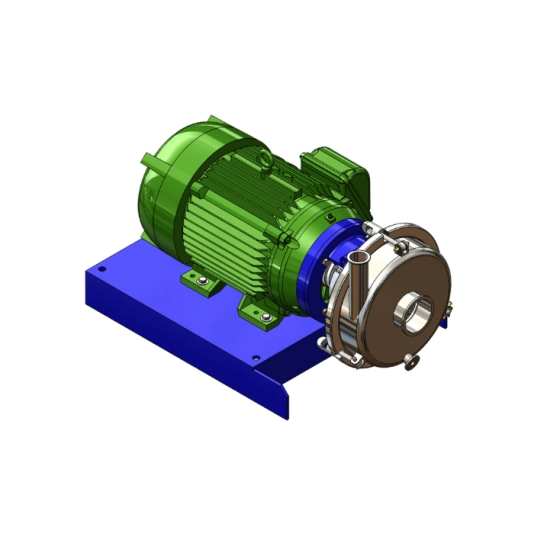

Discflo Sanitary Pumps

Discflo offers two lines of sanitary pumps, the SP Series and MIS Series. Both series meet 3-A sanitary and international hygiene standards and USDA requirements.

They can be supplied in Clean-in-Place or Steam-in-Place versions, and in a variety of metallurgy to meet the user’s requirements.

They can be supplied in Clean-in-Place or Steam-in-Place versions, and in a variety of metallurgy to meet the user’s requirements.

Download

Produk Lainnya

Kennedy Hydraulic Nipple, Straight, 1/8" BSP(T), Steel

Constructed from steel, these hydraulic grease nipples are designed for use with Kennedy® grease guns and all other hydraulic grease equipment.

Features and Benefits

• Ideal for use on Kennedy® grease guns

• Cost effective way of keeping your grease gun working efficiently

• Manufactured from steel for overall durability

• Available in two sizes to suit your requirements

Typical Applications

• For use with Kennedy grease guns and all other hydraulic grease equipment

Features and Benefits

• Ideal for use on Kennedy® grease guns

• Cost effective way of keeping your grease gun working efficiently

• Manufactured from steel for overall durability

• Available in two sizes to suit your requirements

Typical Applications

• For use with Kennedy grease guns and all other hydraulic grease equipment

Kennedy Red-Hot-Dip Hot Dip, Bar, Translucent, 1 Pcs

Hot dip protective plastic coating moulds around the component or tool to provide 100% coverage and protect against impact and corrosion.

Features and Benefits

• Hot dip plastic coating moulds itself around the part to provide 100% coverage and protect against corrosion and impacts for up to ten years

• Easy part identity through the translucent coating

• Simple to remove by peeling off

• Once removed, leaves behind a thin oil film to provide short term protection against corrosion

• Removed coatings may be reused saving cost

Notes

• Each single block measures (L)-150mm (H)-50mm (W)-80mm

• Working temperature 130°C to 160°C (for optimum results 140°C to 145°C)

Warnings

• Never directly apply heat to melt the protective dip

• Always use with a suitable melting pot

Features and Benefits

• Hot dip plastic coating moulds itself around the part to provide 100% coverage and protect against corrosion and impacts for up to ten years

• Easy part identity through the translucent coating

• Simple to remove by peeling off

• Once removed, leaves behind a thin oil film to provide short term protection against corrosion

• Removed coatings may be reused saving cost

Notes

• Each single block measures (L)-150mm (H)-50mm (W)-80mm

• Working temperature 130°C to 160°C (for optimum results 140°C to 145°C)

Warnings

• Never directly apply heat to melt the protective dip

• Always use with a suitable melting pot

Kennedy Hose, Flexible, 1/8" BSP x 500mm, Nylon

For use with Kennedy grease guns, these flexible nylon hoses are designed to improve access in confined spaces. Varying in length and bore size, each product possesses a 1/8" BSP connecting thread.

Features and Benefits

• Flexible nature makes the products suited for use in confined or awkward areas

• Available in a variety of lengths and bore sizes to suit your needs

• Manufactured from nylon for durability and flexibility

Typical Applications

• Automotive

• Engineering

Features and Benefits

• Flexible nature makes the products suited for use in confined or awkward areas

• Available in a variety of lengths and bore sizes to suit your needs

• Manufactured from nylon for durability and flexibility

Typical Applications

• Automotive

• Engineering

Kennedy Hydraulic Nipple, 45°, 1/8"x28 BSP(T), Steel

For use with Kennedy grease guns and all other hydraulic grease equipment.