Pump & Lubricants

Kennedy Hydraulic Nipple, 90°, M10x1.5, Steel

For use with Kennedy grease guns and all other hydraulic grease equipment.

Download

Produk Lainnya

Kennedy Hydraulic Nipple, 45°, 1/4"x19 BSP(T), Steel

For use with Kennedy grease guns and all other hydraulic grease equipment.

Kennedy 20LTR HEAVY DUTY STEEL JERRY CAN (GREEN)

Manufactured from 16 swg steel. Suitable for storing petrol. Suitable for storing and transportation of diesel, paraffin and motor oil. With lever type safety sealing cap and integral carrying handle. Painted outside and phosphated internally.

Features and Benefits

• Strong, ultra-durable material - made from 16 swg steel

• With lever type safety sealing cap and integral carrying handle

• Painted outside and phosphated internally

Notes

• UN Approved, Class 3

Features and Benefits

• Strong, ultra-durable material - made from 16 swg steel

• With lever type safety sealing cap and integral carrying handle

• Painted outside and phosphated internally

Notes

• UN Approved, Class 3

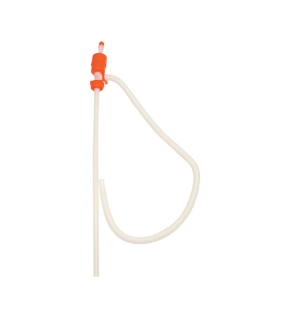

Kennedy SPH/205, Syphon Pump, 205L, Plastic

Available to suit 25 or 205 litre containers, these syphon pumps are an efficient way of controlling and dispensing a host of fluids. Comprised of a flexible plastic outlet and semi-rigid inlet tubes, the hand pumping units incorporate one-way valves. Suited for use with petrol and diesel as well as with non-corrosive liquids. All tubes can be cut to length and are fitted with a threaded bung. Model SPS/25 has a squeeze action and models SPS/205 and SPH/205 have a plunger-type action.

Features and Benefits

• Tubes can be cut to your desired length to meet your requirements

• Suitable for use with petrol, diesel and all non-corrosive liquids

• Available to suit three sized containers

• Flexible nature allows you to manipulate the pump to your desired position

Typical Applications

• Engineering

• Aquatics

• Automotive

Features and Benefits

• Tubes can be cut to your desired length to meet your requirements

• Suitable for use with petrol, diesel and all non-corrosive liquids

• Available to suit three sized containers

• Flexible nature allows you to manipulate the pump to your desired position

Typical Applications

• Engineering

• Aquatics

• Automotive

Moresco Vacuum Pump Oils

NEOVAC is well-known as a synonym for high quality vacuum pump oil. We have received endorsements of NEOVAC as the oil used by many vacuum pump manufacturers due to the high level of trust placed in NEOVAC's performance. NEOVAC is used in vacuum equipment in applications such as semiconductors, silicon wafers, vacuum deposition, heat treatment, and packaging and contributes to productivity improvements.

NEOVAC MR Series

Rotary pump vacuum oil is used with the purposes of lubrication and the preservation of airtight seals. It has a low steam pressure, suitable viscosity, and is difficult to emulsify (it has anti-emulsification properties). In other words, it easily separates from water and removes water.

MR-100 : Standard for small pump

MR-200 : Standard for small pump

MR-250 : Standard for small pump

MR-200A : Improved heat and oxidation. Moisture suction is supported

MR-250A : Improved heat and oxidation. Moisture suction is supported. For large pump

NEOVAC SX & SY

Diffusion pump vacuum oil is sprayed either as molecules or as a steam and is used to obtain a vacuum state. It is necessary for these oils to be chemically stable such as by having low steam pressures, by not being transformed due to heat (heat resistance), and by not reacting easily with oxygen (oxidation resistance).

SX : For surface treatment equipment. (vapor deposition, sputter, heat treatment)

SY : For surface treatment equipment. (vapor deposition, sputter, heat treatment)

NEOVAC MR Series

Rotary pump vacuum oil is used with the purposes of lubrication and the preservation of airtight seals. It has a low steam pressure, suitable viscosity, and is difficult to emulsify (it has anti-emulsification properties). In other words, it easily separates from water and removes water.

MR-100 : Standard for small pump

MR-200 : Standard for small pump

MR-250 : Standard for small pump

MR-200A : Improved heat and oxidation. Moisture suction is supported

MR-250A : Improved heat and oxidation. Moisture suction is supported. For large pump

NEOVAC SX & SY

Diffusion pump vacuum oil is sprayed either as molecules or as a steam and is used to obtain a vacuum state. It is necessary for these oils to be chemically stable such as by having low steam pressures, by not being transformed due to heat (heat resistance), and by not reacting easily with oxygen (oxidation resistance).

SX : For surface treatment equipment. (vapor deposition, sputter, heat treatment)

SY : For surface treatment equipment. (vapor deposition, sputter, heat treatment)