Measuring Tools

Fluke 789 ProcessMeter™

Double your strength

The Fluke 787 was the first device to combine a DMM and a loop calibrator to give process technicians double the power in one tool. Now even better, range is extended in the Fluke 789 – the ultimate loop calibration multimeter. The Fluke 789 has a 24-Volt supply loop which eliminates the need to take a separate power supply when testing transmitters offline. And with selectable onboard 250-Ohm Hart® resistors, the need to carry separate resistors is eliminated. Now process engineers can do more while carrying far less.

The Fluke 787 was the first device to combine a DMM and a loop calibrator to give process technicians double the power in one tool. Now even better, range is extended in the Fluke 789 – the ultimate loop calibration multimeter. The Fluke 789 has a 24-Volt supply loop which eliminates the need to take a separate power supply when testing transmitters offline. And with selectable onboard 250-Ohm Hart® resistors, the need to carry separate resistors is eliminated. Now process engineers can do more while carrying far less.

Download

Produk Lainnya

Fluke Fluke 1507 Insulation Resistance Tester

The Fluke 1507 is a versatile, compact, handheld insulation tester for advanced industrial and electrical insulation testing. Its multiple test voltages make it the ideal tool for many troubleshooting, commissioning, and preventative maintenance applications.

Take advantage of the 1507 full feature set to easily and quickly perform advanced insulation resistance testing. Its handy size and light weight make it easy to pack and use. Additional features, like the remote probe, save both time and money especially when performing repetitive tests. And its reasonable price and rugged reliability make it an excellent value.

Other useful capabilities:

• Performs insulation tests from 0.01 MΩ to 10 GΩ

• Includes live circuit detection to prevent insulation test if voltage >30 V is detected

• Includes auto-discharge of capacitive voltage for added user protection

• Measures AC/DC voltage from 0.1 V to 600 V and resistance from 0.01 Ω to 20.00 kΩ

• Provides lo-ohms earth-bond continuity (200 mA)

• Simplifies repetitive or hard-to-reach testing with the remote test probe

• Saves battery power with auto power off

• Presents results on a large, backlit display

• Features CAT IV 600 V overvoltage category rating

• Comes with remote probe, test leads, test probes, alligator clips and one-year warranty

• Accepts optional Fluke TPAK magnetic hanging system to free your hands for other work

• Runs on four AA alkaline batteries (NEDA 15 A or IEC LR6) for at least 1000 insulation tests

Key Features

• Rugged, compact advanced insulation resistance tester for electrical contractors and industrial and commercial electricians

• Automatically calculates Polarization Index and Dielectric Absorption Ratio

• Makes repetitive tests simple and easy with a Compare (Pass/Fail) function

• Offers multiple insulation test voltages: 50 V, 100 V, 250 V, 500 V, and 1000 V

Take advantage of the 1507 full feature set to easily and quickly perform advanced insulation resistance testing. Its handy size and light weight make it easy to pack and use. Additional features, like the remote probe, save both time and money especially when performing repetitive tests. And its reasonable price and rugged reliability make it an excellent value.

Other useful capabilities:

• Performs insulation tests from 0.01 MΩ to 10 GΩ

• Includes live circuit detection to prevent insulation test if voltage >30 V is detected

• Includes auto-discharge of capacitive voltage for added user protection

• Measures AC/DC voltage from 0.1 V to 600 V and resistance from 0.01 Ω to 20.00 kΩ

• Provides lo-ohms earth-bond continuity (200 mA)

• Simplifies repetitive or hard-to-reach testing with the remote test probe

• Saves battery power with auto power off

• Presents results on a large, backlit display

• Features CAT IV 600 V overvoltage category rating

• Comes with remote probe, test leads, test probes, alligator clips and one-year warranty

• Accepts optional Fluke TPAK magnetic hanging system to free your hands for other work

• Runs on four AA alkaline batteries (NEDA 15 A or IEC LR6) for at least 1000 insulation tests

Key Features

• Rugged, compact advanced insulation resistance tester for electrical contractors and industrial and commercial electricians

• Automatically calculates Polarization Index and Dielectric Absorption Ratio

• Makes repetitive tests simple and easy with a Compare (Pass/Fail) function

• Offers multiple insulation test voltages: 50 V, 100 V, 250 V, 500 V, and 1000 V

Fluke 190-504-III Color ScopeMeter, 500 MHz, 4 channels

Fluke 190-504-III Offers

Accurate and versatile, this portable oscilloscope provides a fast sampling rate of up to 5 GS/s, a 200 ps resolution, and deep memory of 10,000 samples per channel. Perform timing or amplitude-related measurements on three phases or three-axis control systems, or compare and contrast multiple test points in a circuit under test

- Up to four independent floating isolated inputs, up to 1000 V

- Up to 5 GS/s real time sampling (depending on model and channels used)

- Deep memory: 10,000 points per trace waveform capture (scope mode)

- CAT III 1000 V/CAT IV 600 V safety rated instrument for industrial environments

- Up to seven hours of battery operation using BP291

- Large, bright color display is easy to view in nearly any environment

- Easy to store and view historical data and transfer to a PC via USB or Wifi

- Convenient battery access door for quick battery swaps in the field

- IP51 rating, dust and drip-proof

- Connect-and-View triggering for intelligent, automatic triggering on fast, slow and even complex signals

- Frequency spectrum using FFT-analysis

- Automatic capture and REPLAY of 100 screens

- ScopeRecord mode gives 30,000 points per input channel for low frequency signal analysis

- TrendPlot Paperless Recorder mode with deep memory for longterm automatic measurements

- 5000 count DMM included in the 2-channel models

Applications

- Microelectronics

- Troubleshooting

Measure from mV to kV safely

Independently isolated inputs allow you to make measurements in mixed circuits having different ground references reducing the risk of accidental short circuits. Conventional bench oscilloscopes without special differential probes and isolation transformers can only reference measurements to line power earth ground. ScopeMeter 190 Series III test tools are engineered to cover a wide application range from mV to kV, so you’re ready for anything from microelectronics to heavy duty higher voltage electrical applications. 190 Series III 60 MHz and 100 MHz configurations include VPS421 100:1 probes for higher voltage applications, while the 200 MHz and 500 MHz configurations include VPS410-II 10:1 probes suitable for both microelectronics and higher voltage applications.

IP-51 rated for harsh environments

Rugged and shock-proof, ScopeMeter Test Tools are built for dirty, hazardous environments. With its sealed case, it can endure dust, drips, humidity and airborne pollutants. Every time you reach for ScopeMeter Test Tool you can be confident it will work reliably wherever your work takes you.

USB and Wi-Fi connectivity

The Fluke 190 Series III offers two USB ports, electrically isolated from measurement input circuits allowing you to quickly and easily transfer data to a PC, archive and share waveforms with OEMs, colleagues and support staff, or store waveforms, screen captures and instrument setups onto USB memory devices for later use. Easily transfer saved files via USB stick, direct connection via the USB interface or optional Wi-Fi connectivity. These files can be used for further data handling or in FlukeView-2 Software to study waveforms in greater detail.

Connect-and-View triggering

Connect-and-View triggering provides an instant, stable display without the need for adjusting settings. If you’ve used other scopes, you know how tricky triggering can be. If settings are incorrect, results can be unstable or incorrect. Connect-and-View automatically sets up correct triggering by recognizing signal patterns. Without touching a button, you get a stable, reliable and repeatable display of virtually any signal including motor drive and control signals. It’s especially fast and convenient when you’re measuring a number of test points in rapid succession.

Built-in digital multimeter

Conveniently switch from waveform analysis to precise multimeter measurements using the built in 5000 count digital multimeter on two channel 190 Series III models. Measurement functions include Vdc, Vac, Vac+dc, resistance, continuity and diode test. Measure current and temperature using suitable shunt, probe or adapter with wide range of scaling factors.

TrendPlot paperless recorder— records up to 11 days to help you find intermittent faults

The toughest faults to find are those that happen only once in a while. These intermittent events can be caused by bad connections, dust, dirt, corrosion, or simply broken wiring or connectors. Line outages, dips, swells and interruptions, or the starting and stopping of a motor can also cause a machine to stop. You may not be around when it happens, but the 190 Series III ScopeMeter Test Tool will be.

- Plot minimum and maximum peak values and average over time

- Plot any combination of up to four readings including voltages, amps, temperature, frequency and phase for all inputs, all with time and date stamp to pinpoint faults

Accurate and versatile, this portable oscilloscope provides a fast sampling rate of up to 5 GS/s, a 200 ps resolution, and deep memory of 10,000 samples per channel. Perform timing or amplitude-related measurements on three phases or three-axis control systems, or compare and contrast multiple test points in a circuit under test

- Up to four independent floating isolated inputs, up to 1000 V

- Up to 5 GS/s real time sampling (depending on model and channels used)

- Deep memory: 10,000 points per trace waveform capture (scope mode)

- CAT III 1000 V/CAT IV 600 V safety rated instrument for industrial environments

- Up to seven hours of battery operation using BP291

- Large, bright color display is easy to view in nearly any environment

- Easy to store and view historical data and transfer to a PC via USB or Wifi

- Convenient battery access door for quick battery swaps in the field

- IP51 rating, dust and drip-proof

- Connect-and-View triggering for intelligent, automatic triggering on fast, slow and even complex signals

- Frequency spectrum using FFT-analysis

- Automatic capture and REPLAY of 100 screens

- ScopeRecord mode gives 30,000 points per input channel for low frequency signal analysis

- TrendPlot Paperless Recorder mode with deep memory for longterm automatic measurements

- 5000 count DMM included in the 2-channel models

Applications

- Microelectronics

- Troubleshooting

Measure from mV to kV safely

Independently isolated inputs allow you to make measurements in mixed circuits having different ground references reducing the risk of accidental short circuits. Conventional bench oscilloscopes without special differential probes and isolation transformers can only reference measurements to line power earth ground. ScopeMeter 190 Series III test tools are engineered to cover a wide application range from mV to kV, so you’re ready for anything from microelectronics to heavy duty higher voltage electrical applications. 190 Series III 60 MHz and 100 MHz configurations include VPS421 100:1 probes for higher voltage applications, while the 200 MHz and 500 MHz configurations include VPS410-II 10:1 probes suitable for both microelectronics and higher voltage applications.

IP-51 rated for harsh environments

Rugged and shock-proof, ScopeMeter Test Tools are built for dirty, hazardous environments. With its sealed case, it can endure dust, drips, humidity and airborne pollutants. Every time you reach for ScopeMeter Test Tool you can be confident it will work reliably wherever your work takes you.

USB and Wi-Fi connectivity

The Fluke 190 Series III offers two USB ports, electrically isolated from measurement input circuits allowing you to quickly and easily transfer data to a PC, archive and share waveforms with OEMs, colleagues and support staff, or store waveforms, screen captures and instrument setups onto USB memory devices for later use. Easily transfer saved files via USB stick, direct connection via the USB interface or optional Wi-Fi connectivity. These files can be used for further data handling or in FlukeView-2 Software to study waveforms in greater detail.

Connect-and-View triggering

Connect-and-View triggering provides an instant, stable display without the need for adjusting settings. If you’ve used other scopes, you know how tricky triggering can be. If settings are incorrect, results can be unstable or incorrect. Connect-and-View automatically sets up correct triggering by recognizing signal patterns. Without touching a button, you get a stable, reliable and repeatable display of virtually any signal including motor drive and control signals. It’s especially fast and convenient when you’re measuring a number of test points in rapid succession.

Built-in digital multimeter

Conveniently switch from waveform analysis to precise multimeter measurements using the built in 5000 count digital multimeter on two channel 190 Series III models. Measurement functions include Vdc, Vac, Vac+dc, resistance, continuity and diode test. Measure current and temperature using suitable shunt, probe or adapter with wide range of scaling factors.

TrendPlot paperless recorder— records up to 11 days to help you find intermittent faults

The toughest faults to find are those that happen only once in a while. These intermittent events can be caused by bad connections, dust, dirt, corrosion, or simply broken wiring or connectors. Line outages, dips, swells and interruptions, or the starting and stopping of a motor can also cause a machine to stop. You may not be around when it happens, but the 190 Series III ScopeMeter Test Tool will be.

- Plot minimum and maximum peak values and average over time

- Plot any combination of up to four readings including voltages, amps, temperature, frequency and phase for all inputs, all with time and date stamp to pinpoint faults

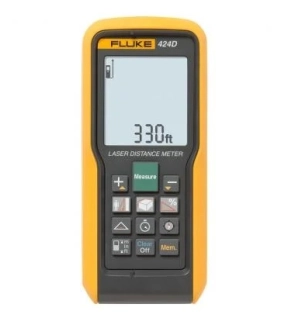

Fluke 424D Laser Distance Meter

- Versatile laser distance meter that instantly measures up to 100 meters (330 feet) with one-button point-and-click operation

- Quickly calculates area (square feet/meters) and volume

- Includes 180° inclination sensor for leveling and height tracking

- Offers enhanced Pythagoras calculation for determining distance indirectly from three other measurements

- Quickly calculates area (square feet/meters) and volume

- Includes 180° inclination sensor for leveling and height tracking

- Offers enhanced Pythagoras calculation for determining distance indirectly from three other measurements

Fluke 62 MAX

Fluke 62 Max Infrared Thermometer delivers single-laser targeting accuracy

The Fluke 62 MAX Infrared thermometer delivers many of the features of the Fluke 62 MAX+, but features a single laser and 10:1 distance to spot ratio. You can use the Fluke 62 MAX to perform non-contact temperature measurements on transformers, motors, pumps, panels, breakers, compressors, duct, steam lines, valves, and vents. It is small in size and extremely easy to use. The single laser helps you pinpoint the target for more accurate readings and makes it easier to measure temperatures in hard to reach areas. With its IP54 rating for dust and water resistance you can rely the Fluke 62 MAX to deliver accurate, repeatable temperature measurements, rain or shine, in even the dirtiest and dustiest industrial sites. And it’s rugged enough to take a 3-meter drop so no worries even if you work from a ladder.

Other useful features:

- High and low alarms for rapid detection of temperatures outside the limits

- Powered by a single, standard AA battery.

- Comes with a three-year warranty -30-

- Withstands a 3 m (9.8 ft.) drop

- Offers small, lightweight form factor to clip comfortably to your tool belt or belt loop, or easily fit in your tool box

- Features a large, backlit display to make data easier to read, even in dark areas.

- Displays Min/Max/Avg/Dif: the minimum, maximum or average temperature, or the difference between two measurements

The Fluke 62 MAX Infrared thermometer delivers many of the features of the Fluke 62 MAX+, but features a single laser and 10:1 distance to spot ratio. You can use the Fluke 62 MAX to perform non-contact temperature measurements on transformers, motors, pumps, panels, breakers, compressors, duct, steam lines, valves, and vents. It is small in size and extremely easy to use. The single laser helps you pinpoint the target for more accurate readings and makes it easier to measure temperatures in hard to reach areas. With its IP54 rating for dust and water resistance you can rely the Fluke 62 MAX to deliver accurate, repeatable temperature measurements, rain or shine, in even the dirtiest and dustiest industrial sites. And it’s rugged enough to take a 3-meter drop so no worries even if you work from a ladder.

Other useful features:

- High and low alarms for rapid detection of temperatures outside the limits

- Powered by a single, standard AA battery.

- Comes with a three-year warranty -30-

- Withstands a 3 m (9.8 ft.) drop

- Offers small, lightweight form factor to clip comfortably to your tool belt or belt loop, or easily fit in your tool box

- Features a large, backlit display to make data easier to read, even in dark areas.

- Displays Min/Max/Avg/Dif: the minimum, maximum or average temperature, or the difference between two measurements