Cutting Tools

Kennedy Toolbit, 4in. x 1/4in., Square, Uncoated

HSS Square Inch.

Cut faster, 'stand up' longer and reduce costs. Square and rectangular toolbits supplied with 15° bevelled ends. Parting-off blades supplied with 2° side taper, 10° bevel (top and bottom).

Cut faster, 'stand up' longer and reduce costs. Square and rectangular toolbits supplied with 15° bevelled ends. Parting-off blades supplied with 2° side taper, 10° bevel (top and bottom).

Download

Produk Lainnya

Granlund Counterbore, N, 16mm, 1N-16,0, High Speed Steel, Bright

Counterbores N with a diameter of 50mm and larger are all made with a driving lip. These sizes should be used in the appropriate type M toolholder.

Dimensions (mm) N, NA & W

Counterbores N, and NA with Ø of 50 mm and larger are all made with a driving lip. These sizes should be used in the appropriate type M toolholder

d: 14.0; d1: 6.0; L: 48.0; L1: 28.0.

Dimensions (mm) N, NA & W

Counterbores N, and NA with Ø of 50 mm and larger are all made with a driving lip. These sizes should be used in the appropriate type M toolholder

d: 14.0; d1: 6.0; L: 48.0; L1: 28.0.

Sherwood Step Drill, 6 to 38, High Speed Steel

HSS multi diameter step drills produce good quality holes in a wide variety of sheet metal, using either a bench drill or light pedestal drilling machine. Manufactured from high speed steel, they offer sound rigidity, strength and stability when machining. Each tool cuts parallel holes in a range of specific sizes and is compatible with materials up to 1/8" (3mm) thick.

Features and Benefits

• High speed steel construction for greater strength, rigidity and stability

• Excellent wear and heat resistance for prolonged tool life

• Cuts parallel holes in sheet metal

Typical Applications

• Drilling

• Sheet metal

Notes

• Available sizes 1-12mm to 6-37mm

Features and Benefits

• High speed steel construction for greater strength, rigidity and stability

• Excellent wear and heat resistance for prolonged tool life

• Cuts parallel holes in sheet metal

Typical Applications

• Drilling

• Sheet metal

Notes

• Available sizes 1-12mm to 6-37mm

York T10, Rotary Burr, Diamond, Single Cut, 3mm, Conical

Suitable for precision grinding of carbide, gems, glass, ceramics, tough alloys, cermets and tool steels, these diamond coated burrs are extremely durable.

Features and Benefits

• Diamond grip mesh is 120/140

• Recommended operating speeds 15,000 - 30,000 rpm

• Diamond coating offers extreme resilience and precise cutting

Typical Applications

• Suitable for precision grinding of carbide, gems, glass, ceramics, tough alloys, cermets, tool steels

Features and Benefits

• Diamond grip mesh is 120/140

• Recommended operating speeds 15,000 - 30,000 rpm

• Diamond coating offers extreme resilience and precise cutting

Typical Applications

• Suitable for precision grinding of carbide, gems, glass, ceramics, tough alloys, cermets, tool steels

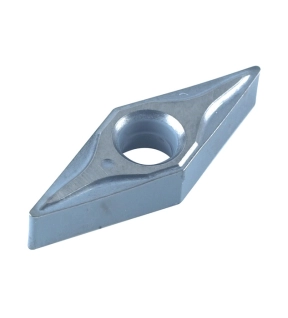

Yamaloy VNMG 12T304-NF1, Turning Insert, Grade QX500, Cermet, 35° Rhombic

VNMG Turning Inserts

35° Rhombic Insert

Insert Grades QX500

(ISO P10-P25) Cerment. For high speed finishing and light cutting. Will remain a high class surface finish. Mainly used on steels and can be applied to finish some Stainless steels and Cast Irons.

Chip Breaker: NFI. Application: Finish.

35° Rhombic Insert

Insert Grades QX500

(ISO P10-P25) Cerment. For high speed finishing and light cutting. Will remain a high class surface finish. Mainly used on steels and can be applied to finish some Stainless steels and Cast Irons.

Chip Breaker: NFI. Application: Finish.