Measuring Tools

Kennedy Euro Tester - 150mm

With heavy duty one-piece moulded insulation sheaths covering both blade and transparent plastic handle for extra protection and safety. Will detect 'live' electricity supply. Suitable for AC to 125 - 250V. 3mm wide tip. Conforms to DIN VDE 0680 part 6:1977-04.

Download

Produk Lainnya

Kennedy 8" SPRING TYPE DIVIDERS-SOLID NUT

Manufactured from high quality polished steel. Ground finished points, a fine adjusting screw is mounted across the legs for setting the distance between the two points. A circular spring bow joins the legs, with a knurled extension attached for use when pivoting the dividers. Dividers are used for scribing arcs and circles, a light centre punch mark on the work keeps the pivot leg in the centre while marking.

Features and Benefits

• High quality polished steel with ground finished points

• Adjusting screw mounted across the legs for setting distance between points

• A light centre punch mark on the work keeps pivot leg in the centre while marking

• Ideal for use in scribing arcs and circle applications

Features and Benefits

• High quality polished steel with ground finished points

• Adjusting screw mounted across the legs for setting distance between points

• A light centre punch mark on the work keeps pivot leg in the centre while marking

• Ideal for use in scribing arcs and circle applications

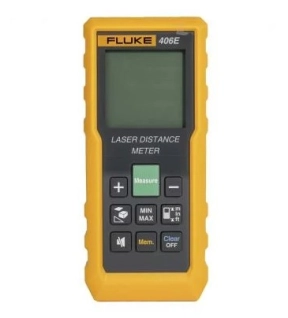

Fluke 404E/406E/405/408/410 Laser Distance Meter

- Quickly measure distance, calculate area / volume / pythagoras

- Auto level and height

- Built to withstand rainy or dusty conditions: 1-meter drop tested with rated IP54 (Fluke 404E / 406E), IP65 (Fluke 405 / 408 / 410),

- Electronic angle display, auxiliary level measurement

- Up to 100 sets of data storage

- The battery life up to 5000 single measurements Automatically power off after 3 minutes of inactivity

Fluke 405 / 408 / 410 provide additional features as :

- Universal tripod interface, easy to use

- Type-C charging port, strong endurance

- 2-inch HD display, clear viewing in full sunlight

- Auto level and height

- Built to withstand rainy or dusty conditions: 1-meter drop tested with rated IP54 (Fluke 404E / 406E), IP65 (Fluke 405 / 408 / 410),

- Electronic angle display, auxiliary level measurement

- Up to 100 sets of data storage

- The battery life up to 5000 single measurements Automatically power off after 3 minutes of inactivity

Fluke 405 / 408 / 410 provide additional features as :

- Universal tripod interface, easy to use

- Type-C charging port, strong endurance

- 2-inch HD display, clear viewing in full sunlight

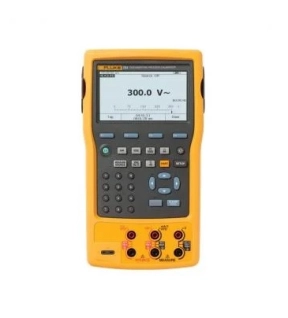

Fluke 754 Documenting Process Calibrator-HART

Portable multi-function calibrator simplifies calibration work

Whether you're calibrating instruments, troubleshooting a problem, or running routine maintenance, the Fluke 754 with HART® communication can help you get the job done faster. It does many different tasks quickly and it's the only process calibrator you need to carry. This rugged, reliable, integrated communicating calibrator is ideal for calibrating, maintaining, and troubleshooting HART smart transmitters and other instrumentation.

Measurement and source capabilities:

- AC/DC voltage

- mA loop w/ 24V loop power

- Pressure

- Thermocouples & RTDs

- Frequency

- Resistance

Enhanced process calibrator operation

With the bright white dual display, you’ll be able to read both sourced and measured parameters simultaneously. The rechargeable Li-Ion battery offers up to 10 hours uninterrupted usage allowing you to complete one task after another without needing to stop, and also includes direct AC power capabilities if needed. Finally, communicate with HART smart digital transmitters directly through the mA measurement jacks for seamless calibration with fewer connections.

Do more, with less

The 754 does the work of several tools. It sources, simulates and measures pressure, temperature, and electrical signals with one rugged, hand-held device. The powerful built-in HART interface can perform nearly all day-to-day tasks you now perform with a separate digital communicator. It can handle fast-pulsed RTD transmitters and PLCs, with pulses as short as 1 ms. The 754 also measures/sources pressure using any of the Fluke 750P Series Pressure Modules as a reference and boasts many additional features like:

- Custom auto-step and ramping

- Custom units

- User-entered values during test

- One-point and two-point switch testing

- Square root DP flow testing

- Programmable measurement delay

Download procedures, lists, and instructions

The 754 is a power multifunction documenting calibrator that you can use to download procedures, lists, and instructions created with software, or upload data for printing, archiving, and analysis. The tool can hold up to a full week of downloaded procedures and calibration results and offers compatibility with many asset management software. Users can also create and run automated as-found or as-left procedures to satisfy quality programs or regulations, and records and documents results.

For documentation, the 754 automates calibration procedures and captures your data. And, of course, it helps you meet rigorous standards like ISO 9000, FDA, EPA, and OSHA regulations. Plus, the graphical screen, Li-Ion battery for longer life, USB port, and accessories help you work smarter and faster.

To create a seamless/paperless calibration management system consider adding Fluke DPCTrack2 Calibration Management software.

Whether you're calibrating instruments, troubleshooting a problem, or running routine maintenance, the Fluke 754 with HART® communication can help you get the job done faster. It does many different tasks quickly and it's the only process calibrator you need to carry. This rugged, reliable, integrated communicating calibrator is ideal for calibrating, maintaining, and troubleshooting HART smart transmitters and other instrumentation.

Measurement and source capabilities:

- AC/DC voltage

- mA loop w/ 24V loop power

- Pressure

- Thermocouples & RTDs

- Frequency

- Resistance

Enhanced process calibrator operation

With the bright white dual display, you’ll be able to read both sourced and measured parameters simultaneously. The rechargeable Li-Ion battery offers up to 10 hours uninterrupted usage allowing you to complete one task after another without needing to stop, and also includes direct AC power capabilities if needed. Finally, communicate with HART smart digital transmitters directly through the mA measurement jacks for seamless calibration with fewer connections.

Do more, with less

The 754 does the work of several tools. It sources, simulates and measures pressure, temperature, and electrical signals with one rugged, hand-held device. The powerful built-in HART interface can perform nearly all day-to-day tasks you now perform with a separate digital communicator. It can handle fast-pulsed RTD transmitters and PLCs, with pulses as short as 1 ms. The 754 also measures/sources pressure using any of the Fluke 750P Series Pressure Modules as a reference and boasts many additional features like:

- Custom auto-step and ramping

- Custom units

- User-entered values during test

- One-point and two-point switch testing

- Square root DP flow testing

- Programmable measurement delay

Download procedures, lists, and instructions

The 754 is a power multifunction documenting calibrator that you can use to download procedures, lists, and instructions created with software, or upload data for printing, archiving, and analysis. The tool can hold up to a full week of downloaded procedures and calibration results and offers compatibility with many asset management software. Users can also create and run automated as-found or as-left procedures to satisfy quality programs or regulations, and records and documents results.

For documentation, the 754 automates calibration procedures and captures your data. And, of course, it helps you meet rigorous standards like ISO 9000, FDA, EPA, and OSHA regulations. Plus, the graphical screen, Li-Ion battery for longer life, USB port, and accessories help you work smarter and faster.

To create a seamless/paperless calibration management system consider adding Fluke DPCTrack2 Calibration Management software.

Fluke 54 II B Data Logging Thermometer with Dual Input

The Fluke 50 Series II contact thermometer offers fast response and laboratory accuracy (0.05% + 0.3°C) in a rugged hand test kit.