Pump & Lubricants

Kennedy Suction Gun, 500cc, Metal

With a chrome finish, this oil suction gun is suitable for rapid draining or filling of oil and other non-corrosive liquids. Possessing a working pressure of 90psi/6.2bar and supplied with a flexible 275mm spout.

Features and Benefits

• 500cc capacity allows you to effectively drain or fill without having to release often

• Chrome finish is classic and aesthetically pleasing

• Comes with a 275mm spout for easy draining

Typical Applications

• Engineering

• Automotive

Features and Benefits

• 500cc capacity allows you to effectively drain or fill without having to release often

• Chrome finish is classic and aesthetically pleasing

• Comes with a 275mm spout for easy draining

Typical Applications

• Engineering

• Automotive

Download

Products Lainnya

Yamoto Side Lever Grease Gun, 500cc, Cartridge Fill

With a comfortable lever grip and offset nozzle, this chrome plated steel lever gun has a 500cc lever and is suited to 400g grease cartridges. Supplied with a flexible rubber hose and suited for medium to heavy greases.

Features and Benefits

• Includes a flexible rubber hose to allow you to begin working immediately

• Manufactured from steel for durability and resilience

• Rubber grip around the lever for comfort and grip when administering lubricants

Typical Applications

• Suited for controlled lubrication of medium and heavy greases to your desired work piece

Features and Benefits

• Includes a flexible rubber hose to allow you to begin working immediately

• Manufactured from steel for durability and resilience

• Rubber grip around the lever for comfort and grip when administering lubricants

Typical Applications

• Suited for controlled lubrication of medium and heavy greases to your desired work piece

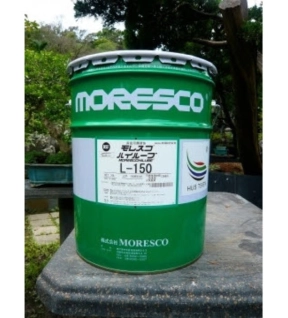

Moresco High Temperature Lubricants

HILUBE

MORESCO-HILUBE, our high temperature lubricating oil, is used in harsh environments as the base oil of greases used with bearings subject to the high temperatures of automotive electrical components and as the lubricating oil used with bearings of machinery such as OA machinery, with bread ovens, and with the drive section of drying furnaces.

L-150 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-320 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-560 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-830 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

MORESCO-HILUBE, our high temperature lubricating oil, is used in harsh environments as the base oil of greases used with bearings subject to the high temperatures of automotive electrical components and as the lubricating oil used with bearings of machinery such as OA machinery, with bread ovens, and with the drive section of drying furnaces.

L-150 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-320 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-560 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-830 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

Kennedy Hydraulic Nipple, Straight, M10x1.5, Steel

Available in three sizes, these metric straight type hydraulic grease nipples are suited for use with Kennedy® grease guns and all other hydraulic grease equipment.

Features and Benefits

• Manufactured from steel for durability

• Available in three varying sizes to suit your specific applications

Typical Applications

• Engineering

• Fluid Handling

• Automotive

Features and Benefits

• Manufactured from steel for durability

• Available in three varying sizes to suit your specific applications

Typical Applications

• Engineering

• Fluid Handling

• Automotive

Kennedy Hydraulic Nipple, 45°, 1/8"x28 BSP(T), Steel

For use with Kennedy grease guns and all other hydraulic grease equipment.