Cutting Tools

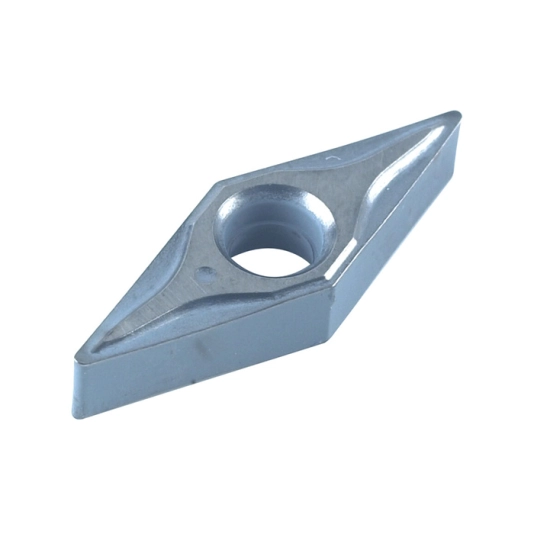

Yamaloy VNMG 12T304-NF1, Turning Insert, Grade QX500, Cermet, 35° Rhombic

VNMG Turning Inserts

35° Rhombic Insert

Insert Grades QX500

(ISO P10-P25) Cerment. For high speed finishing and light cutting. Will remain a high class surface finish. Mainly used on steels and can be applied to finish some Stainless steels and Cast Irons.

Chip Breaker: NFI. Application: Finish.

35° Rhombic Insert

Insert Grades QX500

(ISO P10-P25) Cerment. For high speed finishing and light cutting. Will remain a high class surface finish. Mainly used on steels and can be applied to finish some Stainless steels and Cast Irons.

Chip Breaker: NFI. Application: Finish.

Download

Products Lainnya

Yamaloy TCMT 110204-PM, Turning Insert, Grade QX520, Carbide, Triangle

TCMT Turning Inserts

60° Triangular Insert

Insert Grades QX520

(ISO P10-P35 M10-M30 K10-K30) Coated. An excellent general purpose grade for medium roughing on Steels, Stainless and Cast Irons.

Chip Breaker: PM. Application: Med Cut.

60° Triangular Insert

Insert Grades QX520

(ISO P10-P35 M10-M30 K10-K30) Coated. An excellent general purpose grade for medium roughing on Steels, Stainless and Cast Irons.

Chip Breaker: PM. Application: Med Cut.

SwissBurr F20, High Speed Steel, Hand Deburring Countersink, 20mm x 90°

SwissBurr hand deburring tools are a fast effective and efficient way of deburring holes, slots and edges. Swiss Burr is a totally modular system of interchangeable handles, holders and blades designed to cover all applications. A choice of HSS or carbide blades, countersinks and scrapers are available to suit your specific application. Swiss Burr blades are also interchangeable with commonly available brands including Kennedy, Noga, Ruko, Seco, Snap-Tap and Stellram.

F12 - HSS countersink for hole edges up to 12mm dia.

F20 - HSS countersink for hole edges up to 20mm dia.

F30 - HSS countersink for hole edges up to 30mm dia.

F12 - HSS countersink for hole edges up to 12mm dia.

F20 - HSS countersink for hole edges up to 20mm dia.

F30 - HSS countersink for hole edges up to 30mm dia.

Atlas Workhokders SC105225 55x25x12mm M10 STEP CLAMP

Material: Medium Carbon Steel.

Hardness: HRC 32 - 38.

Surface Finish: Black Oxide.

Hardness: HRC 32 - 38.

Surface Finish: Black Oxide.

Kennedy Holesaw, 25mm x 28.5mm, Bi-metal

The Kennedy® variable pitch hole saws deliver high quality holes in a range of materials, including wood, steel, brass, bronze, and cast iron. The M3 HSS cutting teeth aggressively cut to give a very smooth finish with little to no tear out.

Features and Benefits

• Cuts up to 40% faster than constant pitch saws

• Varying tooth pitch disrupts harmonics to substantially reduce noise

• Tooth life is extended when used in conjuction with a cordless drill

Typical Applications

• Construction

• Engineering

• Maintenance

Notes

• 4-6 teeth per inch

• 28.5mm (11/8") cutting depth

Features and Benefits

• Cuts up to 40% faster than constant pitch saws

• Varying tooth pitch disrupts harmonics to substantially reduce noise

• Tooth life is extended when used in conjuction with a cordless drill

Typical Applications

• Construction

• Engineering

• Maintenance

Notes

• 4-6 teeth per inch

• 28.5mm (11/8") cutting depth