Cutting Tools

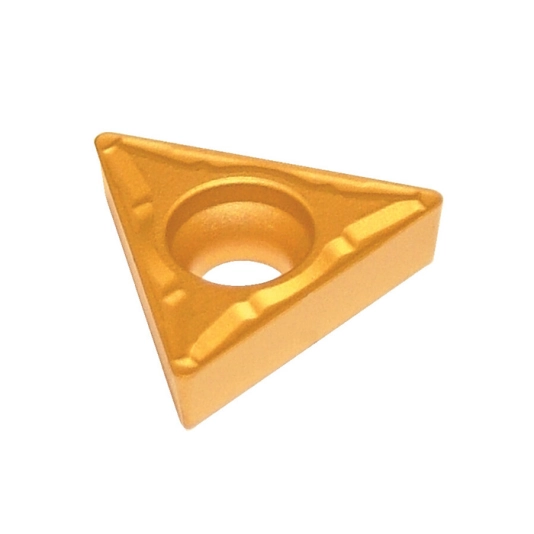

Yamaloy TCMT 110204-PM, Turning Insert, Grade QX520, Carbide, Triangle

TCMT Turning Inserts

60° Triangular Insert

Insert Grades QX520

(ISO P10-P35 M10-M30 K10-K30) Coated. An excellent general purpose grade for medium roughing on Steels, Stainless and Cast Irons.

Chip Breaker: PM. Application: Med Cut.

60° Triangular Insert

Insert Grades QX520

(ISO P10-P35 M10-M30 K10-K30) Coated. An excellent general purpose grade for medium roughing on Steels, Stainless and Cast Irons.

Chip Breaker: PM. Application: Med Cut.

Download

Products Lainnya

Kennedy Masonry Drill Bit, 8mm x 210mm, SDS

Tungsten carbide tipped SDS masonry drills are suitable for all SDS direct fitting hammer drills.

Features and Benefits

• High performance drill bits that withstand extreme heat generation

• Ensures maximum performance combined with wear resistance

Standards Met

• Manufactured to DIN 8035

Notes

• For all hammer drills with SDS, SDS Plus system

Features and Benefits

• High performance drill bits that withstand extreme heat generation

• Ensures maximum performance combined with wear resistance

Standards Met

• Manufactured to DIN 8035

Notes

• For all hammer drills with SDS, SDS Plus system

Kennedy Holesaw, 41mm x 28.5mm, Bi-metal

The Kennedy® variable pitch hole saws deliver high quality holes in a range of materials, including wood, steel, brass, bronze, and cast iron. The M3 HSS cutting teeth aggressively cut to give a very smooth finish with little to no tear out.

Features and Benefits

• Cuts up to 40% faster than constant pitch saws

• Varying tooth pitch disrupts harmonics to substantially reduce noise

• Tooth life is extended when used in conjuction with a cordless drill

Typical Applications

• Construction

• Engineering

• Maintenance

Notes

• 4-6 teeth per inch

• 28.5mm (11/8") cutting depth

Features and Benefits

• Cuts up to 40% faster than constant pitch saws

• Varying tooth pitch disrupts harmonics to substantially reduce noise

• Tooth life is extended when used in conjuction with a cordless drill

Typical Applications

• Construction

• Engineering

• Maintenance

Notes

• 4-6 teeth per inch

• 28.5mm (11/8") cutting depth

Senator Tap & Die Set, M6 - M24, Metric Coarse;Metric Fine, Set of 45

45 piece metric coarse and metric fine combined set of machine ground carbon steel taps and dies supplied in a robust plastic carrying case. Suitable for general workshop and maintenance use only.

Features and Benefits

• Range of coarse and fine combined set

• Machine ground carbon steel taps and dies

• Supplied in a robust protective plastic carrying case

• Tap & Die Sizes: Coarse from M6 to M24 & fine from M6 to M24

Contents

Tap & Die Sizes:

• Coarse: M6 x 1.00, M8 x 1.25, M10 x 1.50, M12 x 1.75, M14 x 2.00, M16 x 2.00, M18 x 1.50, M18 x 2.50, M20 x 1.50, M20 x 2.50, M22 x 2.50, M24 x 3.00

• Fine: M6 x 0.75, M8 x 1.00, M10 x 1.25, M12 x 1.50, M14 x 1.50, M16 x 1.50, M18 x 1.50, M20 x 1.50, M22 x 1.50, M24 x 1.50

• Includes: Tap Wrench, 'T' Type Tap Wrench, Die Holder, Die Adaptor, Flat Bladed Screwdriver

Typical Applications

• Threading

• Tapping

Notes

• For general workshop and maintenance use only

Features and Benefits

• Range of coarse and fine combined set

• Machine ground carbon steel taps and dies

• Supplied in a robust protective plastic carrying case

• Tap & Die Sizes: Coarse from M6 to M24 & fine from M6 to M24

Contents

Tap & Die Sizes:

• Coarse: M6 x 1.00, M8 x 1.25, M10 x 1.50, M12 x 1.75, M14 x 2.00, M16 x 2.00, M18 x 1.50, M18 x 2.50, M20 x 1.50, M20 x 2.50, M22 x 2.50, M24 x 3.00

• Fine: M6 x 0.75, M8 x 1.00, M10 x 1.25, M12 x 1.50, M14 x 1.50, M16 x 1.50, M18 x 1.50, M20 x 1.50, M22 x 1.50, M24 x 1.50

• Includes: Tap Wrench, 'T' Type Tap Wrench, Die Holder, Die Adaptor, Flat Bladed Screwdriver

Typical Applications

• Threading

• Tapping

Notes

• For general workshop and maintenance use only

Kennedy Jobber Drill, 3.5mm, Normal Helix, Cobalt High Speed Steel, Bronze Oxide

The Kennedy range of HSS-Co heavy duty straight shank jobber drills provide durable and reliable cutting performance at high temperatures and speeds thanks to the addition of 5% cobalt to their alloys. Their toughness and heat resistance allows them to to drill steels with tensile strength up to 1,400 N/mm², very hard bronze, stainless steels as well as heat and acid resistant steels.

Long lasting the cutting edges retain their sharpness for longer periods, maximising performance and productivity, whilst also being resistant to corrosion.

Features and Benefits

• Made with a 5% cobalt alloy for optimal performance at high speeds and temperatures

• Allows for optimal cutting of metals up to a tensile strength up to 1,400 N/mm²

• 135° point angle for precise hole making and efficient cutting

• For applications including steel, bronze, stainless and acid resistant steels

• Extended lifespan on cutting edge, required less sharpening over time

• Excellent corrosion resistance extends the lifespan of the tool

Standards

• Manufacturing Standard: BS 328, DIN 338B

Typical Applications

• Cutting and drilling

• Hard metals

• Stainless steel

• Bronze

Notes

• Available in sizes 1-13mm

Long lasting the cutting edges retain their sharpness for longer periods, maximising performance and productivity, whilst also being resistant to corrosion.

Features and Benefits

• Made with a 5% cobalt alloy for optimal performance at high speeds and temperatures

• Allows for optimal cutting of metals up to a tensile strength up to 1,400 N/mm²

• 135° point angle for precise hole making and efficient cutting

• For applications including steel, bronze, stainless and acid resistant steels

• Extended lifespan on cutting edge, required less sharpening over time

• Excellent corrosion resistance extends the lifespan of the tool

Standards

• Manufacturing Standard: BS 328, DIN 338B

Typical Applications

• Cutting and drilling

• Hard metals

• Stainless steel

• Bronze

Notes

• Available in sizes 1-13mm