Measuring Tools

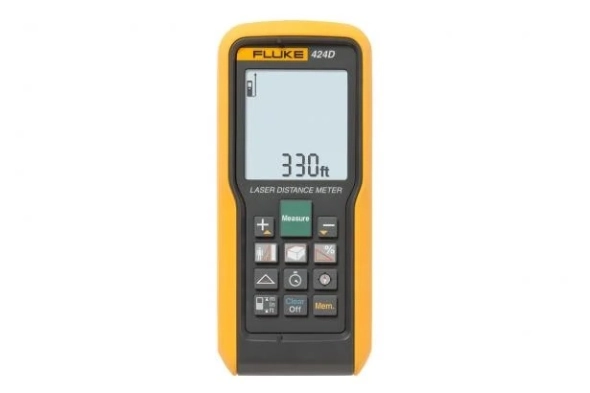

Fluke 424D Laser Distance Meter

- Versatile laser distance meter that instantly measures up to 100 meters (330 feet) with one-button point-and-click operation

- Quickly calculates area (square feet/meters) and volume

- Includes 180° inclination sensor for leveling and height tracking

- Offers enhanced Pythagoras calculation for determining distance indirectly from three other measurements

- Quickly calculates area (square feet/meters) and volume

- Includes 180° inclination sensor for leveling and height tracking

- Offers enhanced Pythagoras calculation for determining distance indirectly from three other measurements

Download

Produk Lainnya

Fluke Fluke 831 Laser Shaft Alignment Tool

Precision laser alignment made easy

The rugged Fluke 831 has an intuitive guided user interface that enables quick and complete shaft alignment without advanced training or complicated programs. And while it’s easy to use, laser alignment with the Fluke 831 is powerful enough for the skilled technician. You can cover more of your machines with all the functionality needed on the plant floor, from thermal growth to user defined tolerances and more.

Reduce costs by avoiding downtime

Misalignment causes at least half of all damage to rotating machinery, studies show. Instead of fixing the problem, teams often just treat the symptoms of misalignment and replace bearings, couplings, and seals because they think alignment takes too long.

Contrary to expectations, laser alignment can be fast and easy. So, every machine that is repaired and overhauled should be aligned – not just a few. Teams that embrace laser alignment can save thousands of dollars per year by avoiding downtime and energy waste and reducing the number of bearings and seals they have to replace.

Key features

• Fast, easy, and precise alignment that adapts to your needs.

• Rugged build and the highest-in-class IP rating.

• Single-laser technology for the fastest, most accurate laser alignment.

• Cloud connection enables real-time collaboration.

• Use up to 8 measurement points to achieve precision alignment on vertical machines.

The rugged Fluke 831 has an intuitive guided user interface that enables quick and complete shaft alignment without advanced training or complicated programs. And while it’s easy to use, laser alignment with the Fluke 831 is powerful enough for the skilled technician. You can cover more of your machines with all the functionality needed on the plant floor, from thermal growth to user defined tolerances and more.

Reduce costs by avoiding downtime

Misalignment causes at least half of all damage to rotating machinery, studies show. Instead of fixing the problem, teams often just treat the symptoms of misalignment and replace bearings, couplings, and seals because they think alignment takes too long.

Contrary to expectations, laser alignment can be fast and easy. So, every machine that is repaired and overhauled should be aligned – not just a few. Teams that embrace laser alignment can save thousands of dollars per year by avoiding downtime and energy waste and reducing the number of bearings and seals they have to replace.

Key features

• Fast, easy, and precise alignment that adapts to your needs.

• Rugged build and the highest-in-class IP rating.

• Single-laser technology for the fastest, most accurate laser alignment.

• Cloud connection enables real-time collaboration.

• Use up to 8 measurement points to achieve precision alignment on vertical machines.

Fluke Fluke 1555 FC 10 kV Insulation Tester

The Fluke 1555 insulation resistance tester offers digital insulation testing up to 10 kV, making it ideal for testing high voltage equipment including switchgear, motors, generators and cables.

Data collection is easy using the Fluke Connect® wireless app. Remote operation lets you spend as little time as possible in potentially hazardous zones. Real-time trending shows a live graph on your phone, rather than a hard-to-read set of changing values. And you can create reports quickly, using pre-designed templates that you can customize with company logos. The 1555 insulation tester can now conduct the entire range of test voltages specified in IEEE 43-2000 with a best in class, 3 year warranty and CAT IV 600 V safety rating.

Other useful features:

• Automatic calculation of Dielectric Absorption (DAR) and Polarization Index (PI) with no additional setup

• Guard system eliminates the effect of surface leakage current on high-resistance measurements

• Selectable test voltages in 50 V steps from 250 V to 1000 V, and 100 V steps above 1000 V

• CAT III 1000 V, CAT IV 600 V safety rating

• Warning function alerts the user that line voltage is present and gives the voltage reading up to 600 V AC or DC for increased user safety

• Measurements can be stored in up to 99 memory locations, with each location assigned a unique, user defined, label for easy recall

• Long battery life gives the user over 750 tests between charges

• Large digital/analog LCD for easy viewing

• Capacitance and leakage current measurement

• Ramp function for breakdown testing

• Resistance measurements up to 2 TΩ

• Timer settings up to 99 minutes for timed tests

• 3-year warranty

Key Features

• Quickly configure, start and stop tests on the 1555 remotely, a safe distance away from any operating, energized equipment, using Fluke Connect® and a smart phone

• Real time trending gives you easy-to-see visual cues, rather than hard to read, rapidly changing values

• Report creation using Fluke Connect desktop saves time and makes test results easier to understand

• Fluke Connect saves test results to the cloud for analysis and preventive maintenance

Data collection is easy using the Fluke Connect® wireless app. Remote operation lets you spend as little time as possible in potentially hazardous zones. Real-time trending shows a live graph on your phone, rather than a hard-to-read set of changing values. And you can create reports quickly, using pre-designed templates that you can customize with company logos. The 1555 insulation tester can now conduct the entire range of test voltages specified in IEEE 43-2000 with a best in class, 3 year warranty and CAT IV 600 V safety rating.

Other useful features:

• Automatic calculation of Dielectric Absorption (DAR) and Polarization Index (PI) with no additional setup

• Guard system eliminates the effect of surface leakage current on high-resistance measurements

• Selectable test voltages in 50 V steps from 250 V to 1000 V, and 100 V steps above 1000 V

• CAT III 1000 V, CAT IV 600 V safety rating

• Warning function alerts the user that line voltage is present and gives the voltage reading up to 600 V AC or DC for increased user safety

• Measurements can be stored in up to 99 memory locations, with each location assigned a unique, user defined, label for easy recall

• Long battery life gives the user over 750 tests between charges

• Large digital/analog LCD for easy viewing

• Capacitance and leakage current measurement

• Ramp function for breakdown testing

• Resistance measurements up to 2 TΩ

• Timer settings up to 99 minutes for timed tests

• 3-year warranty

Key Features

• Quickly configure, start and stop tests on the 1555 remotely, a safe distance away from any operating, energized equipment, using Fluke Connect® and a smart phone

• Real time trending gives you easy-to-see visual cues, rather than hard to read, rapidly changing values

• Report creation using Fluke Connect desktop saves time and makes test results easier to understand

• Fluke Connect saves test results to the cloud for analysis and preventive maintenance

Fluke 1738/INTL Network diagnostics 3-phase Data logger, Clamp meter

The three-phase power logger with the mobile app and desktop software Fluke Connect® is compatible, offers you the data you need to make informed decisions for the optimisation of power quality and energy consumption. As the ideal measuring instrument for energy studies and basic power quality logging records and logs the Power Logger automatically supply quality parameters, so that you get more insight into the data and both the reliability of the system as well as the savings can optimize.

This text is machine translated.

Highlights & Details

- Includes 4 Flex clamp-on ammeter

- This text is machine translated.

Facts

- Automatic Capture and logging of over 500 power supply quality parameters

- Via Fluke Connect® users may the recorded data can be displayed either on site or remotely

- Direct supply of the logger via the measured line and the intelligent review feature reduces the measuring errors significantly

- Software Fluke Energy Analysis Plus enables the measurement results to capture, display, identify problems and detailed reports

- Load studies.

- Energy assessments

- Harmonic measurements

- Recording of voltage events

- Recording of voltage events

- Extended analysis according to EN50160 and waveform snapshots

- Optional IEEE 519 distortion factor measurements.

Delivery

- 1 x PSU

- 1x voltage measuring leads

- 4x alligator clips

- 4x flexible current probes (30 cm, 1500A)

- 1x Carrying Case

- 1 x energy analysis software

- 1x power cord

- 1 x color coding set

- Documentation on USB flash drive

- 1 x magnetic suspension belt

- 4 x magnetic voltage measuring tips.

This text is machine translated.

Highlights & Details

- Includes 4 Flex clamp-on ammeter

- This text is machine translated.

Facts

- Automatic Capture and logging of over 500 power supply quality parameters

- Via Fluke Connect® users may the recorded data can be displayed either on site or remotely

- Direct supply of the logger via the measured line and the intelligent review feature reduces the measuring errors significantly

- Software Fluke Energy Analysis Plus enables the measurement results to capture, display, identify problems and detailed reports

- Load studies.

- Energy assessments

- Harmonic measurements

- Recording of voltage events

- Recording of voltage events

- Extended analysis according to EN50160 and waveform snapshots

- Optional IEEE 519 distortion factor measurements.

Delivery

- 1 x PSU

- 1x voltage measuring leads

- 4x alligator clips

- 4x flexible current probes (30 cm, 1500A)

- 1x Carrying Case

- 1 x energy analysis software

- 1x power cord

- 1 x color coding set

- Documentation on USB flash drive

- 1 x magnetic suspension belt

- 4 x magnetic voltage measuring tips.

Fluke 393 Solar Clamp Meter CAT III 1500 V

The Fluke 393 FC CAT III 1500 V True-rms Solar Clamp Meter with iFlex is designed for solar photovoltaic (PV) installation technicians and maintenance professionals who work in high voltage DC environments: PV arrays, wind power, electric railways, data centers battery banks for uninterruptible power supplies. The clamp meter will measure up to 1500 V DC and 1000 V AC with test leads, and up to 999.9 A DC or AC through the clamp jaw. The included iFlex flexible current probe extends AC current measurements up to 2500 A. The 393 has a thin jaw, giving you access to cables in crowded combiner boxes. Plus, the test leads are designed with your work in mind, and are also rated to CAT III 1500 V DC.

Key functions of the solar clamp meter:

- IP54 rated, ideal for work outdoors including PV panel testing

- DC power measurement, showing readings in kVA

- Audio Polarity indicator helps prevent accidental miswires

- Visual Continuity provides a bright green light in the display, ideal when working in dark and noisy environments

- Logging and reporting of test results via Fluke Connect software

- When measuring ac current the included iFlex flexible current probe gives you unparalleled access to cable is tight spaces. The iFlex probe can be twisted through extremely small spaces and provide accurate current measurements.

The world's first CAT III 1500 V true-RMS solar clamp meter

Key functions of the solar clamp meter:

- IP54 rated, ideal for work outdoors including PV panel testing

- DC power measurement, showing readings in kVA

- Audio Polarity indicator helps prevent accidental miswires

- Visual Continuity provides a bright green light in the display, ideal when working in dark and noisy environments

- Logging and reporting of test results via Fluke Connect software

- When measuring ac current the included iFlex flexible current probe gives you unparalleled access to cable is tight spaces. The iFlex probe can be twisted through extremely small spaces and provide accurate current measurements.

The world's first CAT III 1500 V true-RMS solar clamp meter