Measuring Tools

Fluke 1732/INTL Three Phase Power Energy Monitor & Logger, Battery-Powered

Fluke 1732 3 phase Electrical Energy Logger

Energy logging is now within your reach—discover where you’re wasting energy, optimize your facility’s energy use and reduce your bill. The new Fluke 1732 Three-Phase Electrical Energy loggers introduce a new simplicity to discovering sources of electrical energy waste. Discover when and where energy in your facility is being consumed; from the service entrance to individual circuits.

Profiling energy usage across your facility helps you identify opportunities for energy savings, and provides you with the data you need to act on them. The new Energy Analyse software package allows you to compare multiple data points over time to build a complete picture of energy usage, which is the first step to reduce the cost of your energy bill.

Features and Benefits

• Key Measurements: Automatically capture and log voltage, current, power, power factor, energy and associated values

• Bright, colour touch screen, perform convenient in-the-field analysis and data checks with full graphical display

• Comprehensive Logging: More than 20 separate logging sessions can be stored on the instruments.

• Optimised User Interface: Quick, guided, graphical setup ensures that you are capturing the right data every time, and the intelligent verification function indicates that correct connections have been made, reducing user uncertainty

• Convenient Instrument Powering: Power instrument directly from the measured circuit

• Highest safety rating in the industry: 600 V CAT IV/1000 V CAT III rated for use at the service entrance and downstream

• Measure all 3 phases with included 3 flexible current probes

• Complete “in-the-field"" setup through the front panel or Fluke Connect: No need to return to the workshop for download and setup or to take a computer to the electrical panel

• Fluke Connect® compatible: View data locally on the instrument, via Fluke Connect mobile app and desktop software or through your facilities’ WiFi infrastructure

• Energy Analyse Plus application software: Download and analyse every detail of energy consumption with our automated reporting

Fluke 1732/B Contents

Energy logger, basic version (excludes current probes), power supply, voltage test leads, alligator clips (4x), soft case, energy analyse plus software, line cords, colour coding set and documentation on USB flash drive

Fluke 1732/INTL Contents

Energy logger, International version (includes current probes), power supply, voltage test leads, alligator clips (4x), 12 in 1500 A flexible current probe (3x), soft case, energy analyse plus software, line cords, colour coding set and documentation on USB flash drive

Note:

CRITICAL SAFETY ALERT - PLEASE READ! Fluke has determined that certain improper use of the test lead set, 3PHVL-1730 or 3PHVL-1735-5M 'Voltage Test Lead, 3-phase + N', included with the 173x Series, 174x Series Power Quality Loggers and 3540FC Power Monitor, may potentially expose users to hazardous conditions, posing the risk of serious personal injury or death.

Energy logging is now within your reach—discover where you’re wasting energy, optimize your facility’s energy use and reduce your bill. The new Fluke 1732 Three-Phase Electrical Energy loggers introduce a new simplicity to discovering sources of electrical energy waste. Discover when and where energy in your facility is being consumed; from the service entrance to individual circuits.

Profiling energy usage across your facility helps you identify opportunities for energy savings, and provides you with the data you need to act on them. The new Energy Analyse software package allows you to compare multiple data points over time to build a complete picture of energy usage, which is the first step to reduce the cost of your energy bill.

Features and Benefits

• Key Measurements: Automatically capture and log voltage, current, power, power factor, energy and associated values

• Bright, colour touch screen, perform convenient in-the-field analysis and data checks with full graphical display

• Comprehensive Logging: More than 20 separate logging sessions can be stored on the instruments.

• Optimised User Interface: Quick, guided, graphical setup ensures that you are capturing the right data every time, and the intelligent verification function indicates that correct connections have been made, reducing user uncertainty

• Convenient Instrument Powering: Power instrument directly from the measured circuit

• Highest safety rating in the industry: 600 V CAT IV/1000 V CAT III rated for use at the service entrance and downstream

• Measure all 3 phases with included 3 flexible current probes

• Complete “in-the-field"" setup through the front panel or Fluke Connect: No need to return to the workshop for download and setup or to take a computer to the electrical panel

• Fluke Connect® compatible: View data locally on the instrument, via Fluke Connect mobile app and desktop software or through your facilities’ WiFi infrastructure

• Energy Analyse Plus application software: Download and analyse every detail of energy consumption with our automated reporting

Fluke 1732/B Contents

Energy logger, basic version (excludes current probes), power supply, voltage test leads, alligator clips (4x), soft case, energy analyse plus software, line cords, colour coding set and documentation on USB flash drive

Fluke 1732/INTL Contents

Energy logger, International version (includes current probes), power supply, voltage test leads, alligator clips (4x), 12 in 1500 A flexible current probe (3x), soft case, energy analyse plus software, line cords, colour coding set and documentation on USB flash drive

Note:

CRITICAL SAFETY ALERT - PLEASE READ! Fluke has determined that certain improper use of the test lead set, 3PHVL-1730 or 3PHVL-1735-5M 'Voltage Test Lead, 3-phase + N', included with the 173x Series, 174x Series Power Quality Loggers and 3540FC Power Monitor, may potentially expose users to hazardous conditions, posing the risk of serious personal injury or death.

Download

Produk Lainnya

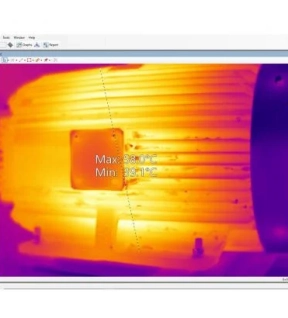

Fluke SmartView R&D Thermal Imaging Software

- Customizable reports - display the information you need based on your application

- Real time radiometric data streaming capability

- Data trending and time plots

- Advanced analysis features; Spot measures, lines/profiles, area/histograms, hot/cold markers, rulers, adjustable emmisivity by object, and more

- Easy to use file management

- Real time radiometric data streaming capability

- Data trending and time plots

- Advanced analysis features; Spot measures, lines/profiles, area/histograms, hot/cold markers, rulers, adjustable emmisivity by object, and more

- Easy to use file management

Fluke RSE600 Mounted Infrared Camera

When it's not just infrared.

Introducing Fluke infrared cameras, the first with full radiometry technology – the RSE series. Packed with advanced features and plug-in software for MATLAB® and LabVIEW® , these tools are ideal for continuous streaming and analysis of infrared data.

Designed for your research, science and engineering needs, enhance your testing and quality assurance procedures by attaching the RSE600 to your workstation. Continuously stream up to 60 frames per second of data directly to your computer to monitor minute temperature differences, as well as analyze remote video frame-by-frame from the SmartView® desktop software . Get an even more perfect screen with add-on lenses to target different applications (analyzing from a distance, or getting detailed close-ups).

Don't just look at the heat. Stream, measure and analyze its power as well.

With plug-ins for MATLAB® and LabVIEW® , the RSE Infrared Camera is perfect for testing and development. Looking for more robust software to monitor and archive processing manufacturing data 24/7? We recommend the ThermoView® series from Fluke Process Instruments. Check out a quick comparison

Introducing Fluke infrared cameras, the first with full radiometry technology – the RSE series. Packed with advanced features and plug-in software for MATLAB® and LabVIEW® , these tools are ideal for continuous streaming and analysis of infrared data.

Designed for your research, science and engineering needs, enhance your testing and quality assurance procedures by attaching the RSE600 to your workstation. Continuously stream up to 60 frames per second of data directly to your computer to monitor minute temperature differences, as well as analyze remote video frame-by-frame from the SmartView® desktop software . Get an even more perfect screen with add-on lenses to target different applications (analyzing from a distance, or getting detailed close-ups).

Don't just look at the heat. Stream, measure and analyze its power as well.

With plug-ins for MATLAB® and LabVIEW® , the RSE Infrared Camera is perfect for testing and development. Looking for more robust software to monitor and archive processing manufacturing data 24/7? We recommend the ThermoView® series from Fluke Process Instruments. Check out a quick comparison

Fluke Pro Electric Pressure Calibrator

Fluke 719Pro Electric Pressure Calibrator sources, simulates, and measures mA signals and more

The 719Pro includes a full functioning loop calibrator that sources, simulates and measures mA signals and more making it the ideal test tool for calibrating high accuracy transmitters, pressure switches and pressure gauges.

Get the ultimate in measurement flexibility with the large backlit screen, which displays three parameters at once:

- Pressure measurement from internal or external sensor

- Sourced/simulated or measured mA values

- Temperature measured by optional RTD probe

The 719Pro includes a full functioning loop calibrator that sources, simulates and measures mA signals and more making it the ideal test tool for calibrating high accuracy transmitters, pressure switches and pressure gauges.

Get the ultimate in measurement flexibility with the large backlit screen, which displays three parameters at once:

- Pressure measurement from internal or external sensor

- Sourced/simulated or measured mA values

- Temperature measured by optional RTD probe

Kennedy 20 BLADE SCREW PITCH GAUGE 60 DEG METRIC

Ideal for accurately measuring internal and external thread forms. Manufactured from hardened and polished steel, the blades are precision milled for optimum accuracy. Enclosed in a steel case.

Featrures and Benefits

• Hardened and polished steel for increased durability

• With precision milled blades for accuracy

• Used to internal and external thread forms

• Enclosed in a steel case for easy storage and portability

Featrures and Benefits

• Hardened and polished steel for increased durability

• With precision milled blades for accuracy

• Used to internal and external thread forms

• Enclosed in a steel case for easy storage and portability