Cutting Tools

Kennedy Countersink, 1/2in, Straight Shank, 6 fl, 90°, Cobalt High Speed Steel

Heavy duty construction manufactured from HSS and cobalt for increased hardness and durability with 6 flutes for improved cutting performance and chip control.

Features and Benefits

• HHS-Co construction for improved hardness

• 6 flutes for improved chip control and cutting efficiency

Typical Applications

• Countersinking

Standards

• Manufactured to BS 328:Part 5:1983

Features and Benefits

• HHS-Co construction for improved hardness

• 6 flutes for improved chip control and cutting efficiency

Typical Applications

• Countersinking

Standards

• Manufactured to BS 328:Part 5:1983

Download

Produk Lainnya

Sherwood Jobber Drill, 8mm, Normal Helix, High Speed Steel, Black Oxide

The J100 Series are general purpose HSS straight shank drills with a black oxide finish. Ideal for applications involving steel (including cast steel) cast iron (including malleable cast iron) as well as nickel, brass aluminium alloys and graphite. Their 118° point allows for precise hole alignment and reliable cutting performance whilst the black oxide coating helps reduce heat by retaining coolant on the tool surface. The coating also helps reduce the risk of the tool staining.

Features and Benefits

• High speed steel construction for increased tool durability

• Point angle of 118° for precise holemaking and precision cutting

• Black oxide coating helps aid chip flow, reduce heat and prevent staining

• Ideal for applications involving steel, iron, nickel, brass, aluminium alloy and graphite

Typical Applications

• Cutting and drilling

• Ferrous materials

• Steel

• Iron

• Nickel

• Brass

• Aluminium alloy

• Graphite

Notes

• Available in sizes 0.25mm -20.00mm

Standards

• Manufactured to BS 328/DIN338RN

Features and Benefits

• High speed steel construction for increased tool durability

• Point angle of 118° for precise holemaking and precision cutting

• Black oxide coating helps aid chip flow, reduce heat and prevent staining

• Ideal for applications involving steel, iron, nickel, brass, aluminium alloy and graphite

Typical Applications

• Cutting and drilling

• Ferrous materials

• Steel

• Iron

• Nickel

• Brass

• Aluminium alloy

• Graphite

Notes

• Available in sizes 0.25mm -20.00mm

Standards

• Manufactured to BS 328/DIN338RN

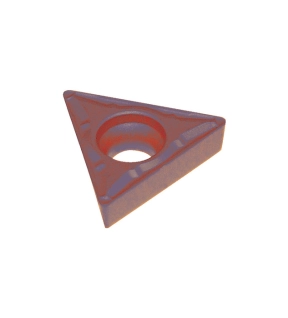

Yamaloy TCMT 16T304-PM, Turning Insert, Grade QX500, Cermet, Triangle

TCMT Turning Inserts

60° Triangular Insert

Insert Grade QX500

(ISO P10-P25) Cerment. For high speed finishing and light cutting. Will remain a high class surface finish. Mainly used on steels and can be applied to finish some Stainless steels and Cast Irons.

Chip Breaker: PM. Application: Med Cut.

60° Triangular Insert

Insert Grade QX500

(ISO P10-P25) Cerment. For high speed finishing and light cutting. Will remain a high class surface finish. Mainly used on steels and can be applied to finish some Stainless steels and Cast Irons.

Chip Breaker: PM. Application: Med Cut.

Kennedy Industrial Carbide Burr Set, Cut 9, 6mm Shank Diameter

The Kennedy® Carbide Burr Set features eight heads with varying nose shapes suitable for use on hard materials such as steel alloys, carbon and cast iron.

Features and Benefits

• Durable carbide construction

• 8-piece set with varying nose shapes to suit the preferred application

• Features a handy carry case for easy storage and tool identification

• Shank diameter: 6mm

• Max. speed (rpm): 40,000

• Chipbreaker (Cut 9): for use on cast iron, carbon steel, alloy steel 50RC and 60RC

Contents

• 1x C shape ball nosed cylinder 9.6 x 19mm

• 1x E shape oval 9.6 x 16mm

• 1x F shape ball nosed tree 9.6 x 19mm

• 1x G-shape pointed tree 9.6 x 19mm

• 1x A shape cylinder without end cut 9.6 x 19mm

• 1x C shape ball nosed cylinder 12.7 x 25mm

• 1x D shape ball 12.7 x 11mm

• 1x F shape ball nosed tree 12.7 x 25mm

Typical Applications

• Milling

• Deburring

Warnings

• Not suitable for milling large amounts of material

Features and Benefits

• Durable carbide construction

• 8-piece set with varying nose shapes to suit the preferred application

• Features a handy carry case for easy storage and tool identification

• Shank diameter: 6mm

• Max. speed (rpm): 40,000

• Chipbreaker (Cut 9): for use on cast iron, carbon steel, alloy steel 50RC and 60RC

Contents

• 1x C shape ball nosed cylinder 9.6 x 19mm

• 1x E shape oval 9.6 x 16mm

• 1x F shape ball nosed tree 9.6 x 19mm

• 1x G-shape pointed tree 9.6 x 19mm

• 1x A shape cylinder without end cut 9.6 x 19mm

• 1x C shape ball nosed cylinder 12.7 x 25mm

• 1x D shape ball 12.7 x 11mm

• 1x F shape ball nosed tree 12.7 x 25mm

Typical Applications

• Milling

• Deburring

Warnings

• Not suitable for milling large amounts of material

York Carbide Burr, Uncoated, Cut 6 - Double Cut, 3mm, Conical

Conical Shape.

All sizes are nominal with a 6mm shank unless other wise stated.

Cut Numbers:

Cut 6 - Double Cut.

Crosscut and double cut to improve control and chipbreaks. Manufactured from high grade tungsten carbide for general-purpose use.

Cut 9 - Chipbreaker

Chipbreaker fast stock removal for improved control and reduced chips for use on hard materials, i.e. steel alloy 50RC, 60RC, carbon and cast iron.

Suitable for deburring and polishing of cast iron, cast steel, carbon steel, alloy steel and stainless steel etc.

up to HRC65 hardness.

Please note:

• Work piece and tools should always be steady and well supported.

• Carbide burrs are not suitable for 'milling' large amounts of material, they are for light stock removal and high revolutions 'LOW FEED - HIGH SPEED'.

• Always ensure that at least 70% of the shank length is clamped by the collet or chuck of the tool being used.

• Always ensure that the tool is rated to the recommended operating speed of the burr.

All sizes are nominal with a 6mm shank unless other wise stated.

Cut Numbers:

Cut 6 - Double Cut.

Crosscut and double cut to improve control and chipbreaks. Manufactured from high grade tungsten carbide for general-purpose use.

Cut 9 - Chipbreaker

Chipbreaker fast stock removal for improved control and reduced chips for use on hard materials, i.e. steel alloy 50RC, 60RC, carbon and cast iron.

Suitable for deburring and polishing of cast iron, cast steel, carbon steel, alloy steel and stainless steel etc.

up to HRC65 hardness.

Please note:

• Work piece and tools should always be steady and well supported.

• Carbide burrs are not suitable for 'milling' large amounts of material, they are for light stock removal and high revolutions 'LOW FEED - HIGH SPEED'.

• Always ensure that at least 70% of the shank length is clamped by the collet or chuck of the tool being used.

• Always ensure that the tool is rated to the recommended operating speed of the burr.