Cutting Tools

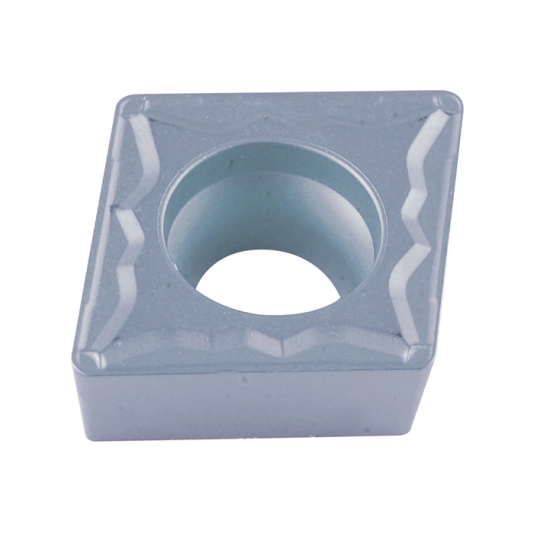

Yamaloy CCMT 09T308-PM, Turning Insert, Grade QX5020, Carbide, 80° Rhombic

CCMT Turning Inserts

80° Rhombic Insert

Insert Grade QX5020

(ISO P10-P35 M10-M30 K10-K30) CVD Coated. An excellent general purpose grade for medium roughing on Steels, Stainless and Cast Irons.

Chip Breaker: PM. Application: Med Cut.

80° Rhombic Insert

Insert Grade QX5020

(ISO P10-P35 M10-M30 K10-K30) CVD Coated. An excellent general purpose grade for medium roughing on Steels, Stainless and Cast Irons.

Chip Breaker: PM. Application: Med Cut.

Download

Produk Lainnya

York 30 Piece Diamond Coated Burr Set with 3mm Shank

Set of various style burrs packaged in a handy pocket 'glasses case' style plastic holder. Ideal for the shop floor workman with various de-burring tasks. Suitable for precision grinding of carbide gems, ceramics, tough alloys, cermets, tool steels etc

Features and Benefits

• Diamond coated for improved hardness

• Excellent performance with precise grinding

Contents

• Assorted sizes of ball shape

• Cylindrical

• Ball nose cylindrical

• Tree shape and conical

Specifications

• Diamond grip mesh is 120/140

• recommended operating speeds 15,000 - 30,000

• Up to 4.5mm diameter

• Overall length 45mm

• 3mm shank

Typical Applications

• Grinding

• Carbide gems

• Glass

• Ceramics

• Tough alloys

• Cermets

• Tool steels

Features and Benefits

• Diamond coated for improved hardness

• Excellent performance with precise grinding

Contents

• Assorted sizes of ball shape

• Cylindrical

• Ball nose cylindrical

• Tree shape and conical

Specifications

• Diamond grip mesh is 120/140

• recommended operating speeds 15,000 - 30,000

• Up to 4.5mm diameter

• Overall length 45mm

• 3mm shank

Typical Applications

• Grinding

• Carbide gems

• Glass

• Ceramics

• Tough alloys

• Cermets

• Tool steels

Kennedy Toolbit, 100mm x 12mm, Square, Uncoated

5% Cobalt Square Metric.

Cut faster, 'stand up' longer and reduce costs. Square and rectangular toolbits supplied with 15° bevelled ends. Parting-off blades supplied with 2° side taper, 10° bevel (top and bottom).

Cut faster, 'stand up' longer and reduce costs. Square and rectangular toolbits supplied with 15° bevelled ends. Parting-off blades supplied with 2° side taper, 10° bevel (top and bottom).

York Carbide Burr, Uncoated, Cut 6 - Double Cut, 6mm, Conical

Cut 6 carbide rotary burrs feature a crosscut and double cut to improve control and chipbreaks. Manufactured from high grade tungsten carbide for general-purpose use.

Features and Benefits

• Manufactured from carbide for greater hardness

• Cut 6 crosscut and double cut to improve control and chipbreaks

• Suitable for use on hard materials up to HRC65 hardness

Typical Applications

• Deburring

• Cast iron

• Cast steel

• Carbon steel

• Alloy steel

• Stainless steel

Notes

• Work piece and tools should always be steady and well supported

• Carbide burrs are not suitable for 'milling' large amounts of material, they are for light stock removal and high revolutions 'LOW FEED - HIGH SPEED'

• Always ensure that at least 70% of the shank length is clamped by the collet or chuck of the tool being used

• Always ensure that the tool is rated to the recommended operating speed of the burr

Cut 6 - Double Cut.

Cut 9 - Chipbreaker

Chipbreaker fast stock removal for improved control and reduced chips for use on hard materials, i.e. steel alloy 50RC, 60RC, carbon and cast iron.

Suitable for deburring and polishing of cast iron, cast steel, carbon steel, alloy steel and stainless steel etc.

up to HRC65 hardness.

Please note:

• Work piece and tools should always be steady and well supported.

• Carbide burrs are not suitable for 'milling' large amounts of material, they are for light stock removal and high revolutions 'LOW FEED - HIGH SPEED'.

• Always ensure that at least 70% of the shank length is clamped by the collet or chuck of the tool being used.

• Always ensure that the tool is rated to the recommended operating speed of the burr.

Features and Benefits

• Manufactured from carbide for greater hardness

• Cut 6 crosscut and double cut to improve control and chipbreaks

• Suitable for use on hard materials up to HRC65 hardness

Typical Applications

• Deburring

• Cast iron

• Cast steel

• Carbon steel

• Alloy steel

• Stainless steel

Notes

• Work piece and tools should always be steady and well supported

• Carbide burrs are not suitable for 'milling' large amounts of material, they are for light stock removal and high revolutions 'LOW FEED - HIGH SPEED'

• Always ensure that at least 70% of the shank length is clamped by the collet or chuck of the tool being used

• Always ensure that the tool is rated to the recommended operating speed of the burr

Cut 6 - Double Cut.

Cut 9 - Chipbreaker

Chipbreaker fast stock removal for improved control and reduced chips for use on hard materials, i.e. steel alloy 50RC, 60RC, carbon and cast iron.

Suitable for deburring and polishing of cast iron, cast steel, carbon steel, alloy steel and stainless steel etc.

up to HRC65 hardness.

Please note:

• Work piece and tools should always be steady and well supported.

• Carbide burrs are not suitable for 'milling' large amounts of material, they are for light stock removal and high revolutions 'LOW FEED - HIGH SPEED'.

• Always ensure that at least 70% of the shank length is clamped by the collet or chuck of the tool being used.

• Always ensure that the tool is rated to the recommended operating speed of the burr.

Kennedy Jobber Drill Set, 1mm to 10mm x 0.5mm, Standard Length, Metric, Cobalt High Speed Steel, Set of 19

A 19 piece metric heavy duty drill set made of 5% cobalt material with excellent heat resistance. Ideal for drilling steels with tensile strength up to 1,400 N/mm2, very hard bronze, stainless steels as well as heat and acid resistant steels. The high speed steel and cobalt construction allows for greater rigidity when cutting through harder materials.

Features and Benefits

• Manufactured from high speed steel with 5% cobalt for added strength

• Excellent heat and wear resistance for prolonged tool lifespan

• Supplied in a robust carry case for easy portability and storage

Contents

• Set contains 1x 1.0, 1.5, 2.0, 2.5, 3.0, 3.5, 4.0, 4.5, 5.0, 5.5, 6.0, 6.5, 7.0, 7.5, 8.0, 8.5, 9.0, 9.5 and 10.0 mm drills

Specifications

• Point angle: 135°

• Helix angle: normal

• Web thickness: strengthened

• Relief angle: normal

• Tolerance of diameter: h8

• Tolerance of shank: f11

• Supply unit

• All diameters - 1 pc

• Manufacturing Standard: BS 328, DIN 338B

Typical Applications

• Drilling

• Steel

• Hard bronze

• Stainless steels

Features and Benefits

• Manufactured from high speed steel with 5% cobalt for added strength

• Excellent heat and wear resistance for prolonged tool lifespan

• Supplied in a robust carry case for easy portability and storage

Contents

• Set contains 1x 1.0, 1.5, 2.0, 2.5, 3.0, 3.5, 4.0, 4.5, 5.0, 5.5, 6.0, 6.5, 7.0, 7.5, 8.0, 8.5, 9.0, 9.5 and 10.0 mm drills

Specifications

• Point angle: 135°

• Helix angle: normal

• Web thickness: strengthened

• Relief angle: normal

• Tolerance of diameter: h8

• Tolerance of shank: f11

• Supply unit

• All diameters - 1 pc

• Manufacturing Standard: BS 328, DIN 338B

Typical Applications

• Drilling

• Steel

• Hard bronze

• Stainless steels