Cutting Tools

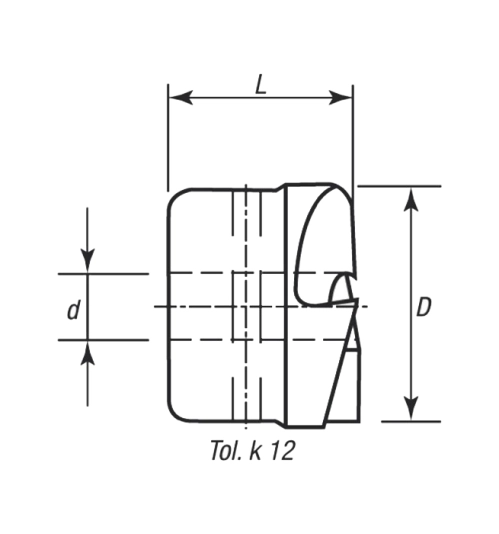

Granlund Backspotfacing Tool, U, 25mm, U-09/25, High Speed Steel, Bright

U-09

Download

Produk Lainnya

Kennedy JIGSAW BLADES (EQV. TO BOSCH T118AF) PKT-5

• T-shank

• For cutting wood and wood-based products (plywood, chipboard etc.) , plastic and metal (thin or perforated sheet)

• Compatible with the majority of modern jigsaws

• Pack of 5

• For cutting wood and wood-based products (plywood, chipboard etc.) , plastic and metal (thin or perforated sheet)

• Compatible with the majority of modern jigsaws

• Pack of 5

Sherwood Jobber Drill, 11mm, Normal Helix, High Speed Steel, Black Oxide

The J100 Series are general purpose HSS straight shank drills with a black oxide finish. Ideal for applications involving steel (including cast steel) cast iron (including malleable cast iron) as well as nickel, brass aluminium alloys and graphite. Their 118° point allows for precise hole alignment and reliable cutting performance whilst the black oxide coating helps reduce heat by retaining coolant on the tool surface. The coating also helps reduce the risk of the tool staining.

Features and Benefits

• High speed steel construction for increased tool durability

• Point angle of 118° for precise holemaking and precision cutting

• Black oxide coating helps aid chip flow, reduce heat and prevent staining

• Ideal for applications involving steel, iron, nickel, brass, aluminium alloy and graphite

Typical Applications

• Cutting and drilling

• Ferrous materials

• Steel

• Iron

• Nickel

• Brass

• Aluminium alloy

• Graphite

Notes

• Available in sizes 0.25mm -20.00mm

Standards

• Manufactured to BS 328/DIN338RN

Features and Benefits

• High speed steel construction for increased tool durability

• Point angle of 118° for precise holemaking and precision cutting

• Black oxide coating helps aid chip flow, reduce heat and prevent staining

• Ideal for applications involving steel, iron, nickel, brass, aluminium alloy and graphite

Typical Applications

• Cutting and drilling

• Ferrous materials

• Steel

• Iron

• Nickel

• Brass

• Aluminium alloy

• Graphite

Notes

• Available in sizes 0.25mm -20.00mm

Standards

• Manufactured to BS 328/DIN338RN

Swisstech Jobber Drill, 6mm, Normal Helix, Cobalt High Speed Steel, TiN-Tipped

Series 1024 HSS-Co Heavy Duty Straight Shank Drills

Tin Tipped - Metric

Heavy-duty drill used to drill steels with a tensile strength up to 1,400 N/mm2. Stainless steels, heat and acid resistant steels and phosphor bronze. TiN coating provides longer tool life.

Point angle: 135°. Helix angle: normal. Web thickness: strengthened. Relief angle: normal.

Tolerance of diameter: h8.

Manufactured to DIN 338 RN.

Tin Tipped - Metric

Heavy-duty drill used to drill steels with a tensile strength up to 1,400 N/mm2. Stainless steels, heat and acid resistant steels and phosphor bronze. TiN coating provides longer tool life.

Point angle: 135°. Helix angle: normal. Web thickness: strengthened. Relief angle: normal.

Tolerance of diameter: h8.

Manufactured to DIN 338 RN.

Kennedy-Pro M8.0x1.00mmx1.5D THREADING INSERTS (PK-10)

This range of metric thread repair inserts includes 1xD, 1.5xD and 2xD lengths (ISO Metric threads). Our quality inserts are now supplied in packs of 10 or 50.

Features and Benefits

• Available in packs of 10 or 50 depending on your selection

• Easy and effective way of repairing threads

• Available in a range of sizes to suit your needs

Typical Applications

• Construction

• Automotive

• Engineering

Features and Benefits

• Available in packs of 10 or 50 depending on your selection

• Easy and effective way of repairing threads

• Available in a range of sizes to suit your needs

Typical Applications

• Construction

• Automotive

• Engineering