kategori Produk

BRAND

Cutting Tools

**Jika tidak menemukan produk yang anda cari, silahkan chat admin melalui whatsapp untuk cek ketersediaan barangnya

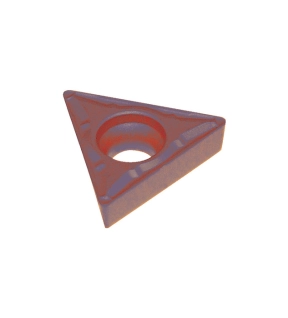

Yamaloy TCMT 16T304-PM, Turning Insert, Grade QX500, Cermet, Triangle

TCMT Turning Inserts

60° Triangular Insert

Insert Grade QX500

(ISO P10-P25) Cerment. For high speed finishing and light cutting. Will remain a high class surface finish. Mainly used on steels and can be applied to finish some Stainless steels and Cast Irons.

Chip Breaker: PM. Application: Med Cut.

60° Triangular Insert

Insert Grade QX500

(ISO P10-P25) Cerment. For high speed finishing and light cutting. Will remain a high class surface finish. Mainly used on steels and can be applied to finish some Stainless steels and Cast Irons.

Chip Breaker: PM. Application: Med Cut.

York Carbide Burr, Uncoated, Cut 6 - Double Cut, 8mm, Ball Nosed Cylindrical

Cut 6 cylindrical ball nosed rotary burrs feature crosscut and double cut profile to improve control and chipbreaks. Manufactured from high grade tungsten carbide for general-purpose use. Suitable for deburring and polishing of cast iron, cast steel, carbon steel, alloy steel and stainless steel, up to HRC65 hardness.

Features and Benefits

• Tungsten carbide construction for improved hardness and strength

• Crosscut and double cut profile to improve and control chipbreaks

Typical Applications

• Deburring

• Steel

• Cast iron

Please note:

• Work piece and tools should always be steady and well supported.

• Carbide burrs are not suitable for 'milling' large amounts of material, they are for light stock removal and high revolutions 'LOW FEED - HIGH SPEED'.

• Always ensure that at least 70% of the shank length is clamped by the collet or chuck of the tool being used.

• Always ensure that the tool is rated to the recommended operating speed of the burr.

Additional

• Image for illustration purposes only

Features and Benefits

• Tungsten carbide construction for improved hardness and strength

• Crosscut and double cut profile to improve and control chipbreaks

Typical Applications

• Deburring

• Steel

• Cast iron

Please note:

• Work piece and tools should always be steady and well supported.

• Carbide burrs are not suitable for 'milling' large amounts of material, they are for light stock removal and high revolutions 'LOW FEED - HIGH SPEED'.

• Always ensure that at least 70% of the shank length is clamped by the collet or chuck of the tool being used.

• Always ensure that the tool is rated to the recommended operating speed of the burr.

Additional

• Image for illustration purposes only

York Carbide Burr, Uncoated, Cut 6 - Double Cut, 3mm, Round Tree

Crosscut and double cut to improve control and chipbreaks. Manufactured from high grade tungsten carbide for general-purpose use. Suitable for deburring and polishing of cast iron, cast steel, carbon steel, alloy steel and stainless steel etc.

up to HRC65 hardness.

Features and Benefits

• Hard carbide construction for increased cutting hardness

• Crosscut and double for improved chip control and chipbreaks

• Suitable for deburring and polishing of materials up to HRC65 hardness

Typical Applications

• Deburring

• Polishing

Please note:

• Work piece and tools should always be steady and well supported

• Carbide burrs are not suitable for 'milling' large amounts of material, they are for light stock removal and high revolutions 'LOW FEED - HIGH SPEED'

• Always ensure that at least 70% of the shank length is clamped by the collet or chuck of the tool being used

• Always ensure that the tool is rated to the recommended operating speed of the burr

up to HRC65 hardness.

Features and Benefits

• Hard carbide construction for increased cutting hardness

• Crosscut and double for improved chip control and chipbreaks

• Suitable for deburring and polishing of materials up to HRC65 hardness

Typical Applications

• Deburring

• Polishing

Please note:

• Work piece and tools should always be steady and well supported

• Carbide burrs are not suitable for 'milling' large amounts of material, they are for light stock removal and high revolutions 'LOW FEED - HIGH SPEED'

• Always ensure that at least 70% of the shank length is clamped by the collet or chuck of the tool being used

• Always ensure that the tool is rated to the recommended operating speed of the burr

York A50, Rotary Burr, Diamond, Single Cut, 5mm, Cylindrical

Suitable for precision grinding of carbide, gems, glass, ceramics, tough alloys, cermets, tool steels etc.

Features and Benefits

• Diamond grip mesh is 120/140 for cutting hard substrates

• Ideal for operating speeds of up to 15,000 - 30,000 rpm

• Range of cutting head sizes to suit application

Typical Applications

• Deburring

• Grinding

• Hard substrates

Features and Benefits

• Diamond grip mesh is 120/140 for cutting hard substrates

• Ideal for operating speeds of up to 15,000 - 30,000 rpm

• Range of cutting head sizes to suit application

Typical Applications

• Deburring

• Grinding

• Hard substrates

Kennedy Jobber Drill, 3mm, Normal Helix, Cobalt High Speed Steel, Bronze Oxide

The Kennedy range of HSS-Co heavy duty straight shank jobber drills provide durable and reliable cutting performance at high temperatures and speeds thanks to the addition of 5% cobalt to their alloys. Their toughness and heat resistance allows them to to drill steels with tensile strength up to 1,400 N/mm², very hard bronze, stainless steels as well as heat and acid resistant steels.

Long lasting the cutting edges retain their sharpness for longer periods, maximising performance and productivity, whilst also being resistant to corrosion.

Features and Benefits

• Made with a 5% cobalt alloy for optimal performance at high speeds and temperatures

• Allows for optimal cutting of metals up to a tensile strength up to 1,400 N/mm²

• 135° point angle for precise hole making and efficient cutting

• For applications including steel, bronze, stainless and acid resistant steels

• Extended lifespan on cutting edge, required less sharpening over time

• Excellent corrosion resistance extends the lifespan of the tool

Standards

• Manufacturing Standard: BS 328, DIN 338B

Typical Applications

• Cutting and drilling

• Hard metals

• Stainless steel

• Bronze

Notes

• Available in sizes 1-13mm

Long lasting the cutting edges retain their sharpness for longer periods, maximising performance and productivity, whilst also being resistant to corrosion.

Features and Benefits

• Made with a 5% cobalt alloy for optimal performance at high speeds and temperatures

• Allows for optimal cutting of metals up to a tensile strength up to 1,400 N/mm²

• 135° point angle for precise hole making and efficient cutting

• For applications including steel, bronze, stainless and acid resistant steels

• Extended lifespan on cutting edge, required less sharpening over time

• Excellent corrosion resistance extends the lifespan of the tool

Standards

• Manufacturing Standard: BS 328, DIN 338B

Typical Applications

• Cutting and drilling

• Hard metals

• Stainless steel

• Bronze

Notes

• Available in sizes 1-13mm

Senator Tap & Die Set, M6 - M24, Metric Coarse;Metric Fine, Set of 45

45 piece metric coarse and metric fine combined set of machine ground carbon steel taps and dies supplied in a robust plastic carrying case. Suitable for general workshop and maintenance use only.

Features and Benefits

• Range of coarse and fine combined set

• Machine ground carbon steel taps and dies

• Supplied in a robust protective plastic carrying case

• Tap & Die Sizes: Coarse from M6 to M24 & fine from M6 to M24

Contents

Tap & Die Sizes:

• Coarse: M6 x 1.00, M8 x 1.25, M10 x 1.50, M12 x 1.75, M14 x 2.00, M16 x 2.00, M18 x 1.50, M18 x 2.50, M20 x 1.50, M20 x 2.50, M22 x 2.50, M24 x 3.00

• Fine: M6 x 0.75, M8 x 1.00, M10 x 1.25, M12 x 1.50, M14 x 1.50, M16 x 1.50, M18 x 1.50, M20 x 1.50, M22 x 1.50, M24 x 1.50

• Includes: Tap Wrench, 'T' Type Tap Wrench, Die Holder, Die Adaptor, Flat Bladed Screwdriver

Typical Applications

• Threading

• Tapping

Notes

• For general workshop and maintenance use only

Features and Benefits

• Range of coarse and fine combined set

• Machine ground carbon steel taps and dies

• Supplied in a robust protective plastic carrying case

• Tap & Die Sizes: Coarse from M6 to M24 & fine from M6 to M24

Contents

Tap & Die Sizes:

• Coarse: M6 x 1.00, M8 x 1.25, M10 x 1.50, M12 x 1.75, M14 x 2.00, M16 x 2.00, M18 x 1.50, M18 x 2.50, M20 x 1.50, M20 x 2.50, M22 x 2.50, M24 x 3.00

• Fine: M6 x 0.75, M8 x 1.00, M10 x 1.25, M12 x 1.50, M14 x 1.50, M16 x 1.50, M18 x 1.50, M20 x 1.50, M22 x 1.50, M24 x 1.50

• Includes: Tap Wrench, 'T' Type Tap Wrench, Die Holder, Die Adaptor, Flat Bladed Screwdriver

Typical Applications

• Threading

• Tapping

Notes

• For general workshop and maintenance use only

Sherwood Hand Tap Set , M10 x 1.5mm, Metric Coarse, High Speed Steel, Bright, Set of 3

A set of three Sherwood HSS Taps ideal for the general purpose option for thread cutting in most materials including steel, some stainless steels, cast irons and non-ferrous materials such as Aluminium, Brass and many others.

Features and Benefits

• Manufactured from durable high speed steel

• Precision ground flutes for accurate thread cutting

• Features class 2 thread forms with medium fit tolerance

• Manufactured with a bright finish

Typical Applications

• Tapping

• Steel

• Brass

• Aluminium

• Engineering

• Manufacturing

Standards

• Tap dimensions to ISO529

• Thread Forms are Class 2 medium fit tolerance

• Straight Flute Individual Sizes IS0 529

Notes

• Available in sizes 1.0 x 0.25mm - 48 x 5.00mm

• Set of 3 - 1 Taper, second and plug

Features and Benefits

• Manufactured from durable high speed steel

• Precision ground flutes for accurate thread cutting

• Features class 2 thread forms with medium fit tolerance

• Manufactured with a bright finish

Typical Applications

• Tapping

• Steel

• Brass

• Aluminium

• Engineering

• Manufacturing

Standards

• Tap dimensions to ISO529

• Thread Forms are Class 2 medium fit tolerance

• Straight Flute Individual Sizes IS0 529

Notes

• Available in sizes 1.0 x 0.25mm - 48 x 5.00mm

• Set of 3 - 1 Taper, second and plug

Sherwood Jobber Drill, 9mm, Normal Helix, High Speed Steel, Black Oxide

The J100 Series are general purpose HSS straight shank drills with a black oxide finish. Ideal for applications involving steel (including cast steel) cast iron (including malleable cast iron) as well as nickel, brass aluminium alloys and graphite. Their 118° point allows for precise hole alignment and reliable cutting performance whilst the black oxide coating helps reduce heat by retaining coolant on the tool surface. The coating also helps reduce the risk of the tool staining.

Features and Benefits

• High speed steel construction for increased tool durability

• Point angle of 118° for precise holemaking and precision cutting

• Black oxide coating helps aid chip flow, reduce heat and prevent staining

• Ideal for applications involving steel, iron, nickel, brass, aluminium alloy and graphite

Typical Applications

• Cutting and drilling

• Ferrous materials

• Steel

• Iron

• Nickel

• Brass

• Aluminium alloy

• Graphite

Notes

• Available in sizes 0.25mm -20.00mm

Standards

• Manufactured to BS 328/DIN338RN

Features and Benefits

• High speed steel construction for increased tool durability

• Point angle of 118° for precise holemaking and precision cutting

• Black oxide coating helps aid chip flow, reduce heat and prevent staining

• Ideal for applications involving steel, iron, nickel, brass, aluminium alloy and graphite

Typical Applications

• Cutting and drilling

• Ferrous materials

• Steel

• Iron

• Nickel

• Brass

• Aluminium alloy

• Graphite

Notes

• Available in sizes 0.25mm -20.00mm

Standards

• Manufactured to BS 328/DIN338RN

Swisstech Jobber Drill, 6mm, Normal Helix, High Speed Steel, TiN

Swiss+Tech HSS Straight Shank TiN Tipped Jobber Drills are coated in a durable Titanium Nitrile at the tip for optimal tool life and performance when undertaking cutting applications. Their ground flute construction and bright body gives a more precise finish and therefore better cutting precision, making them ideal for use with steel, cast steel alloyed and non-alloyed, grey cast iron, graphite and malleable cast iron.

Features and Benefits

• Hardy TiN tipped coating for optimal performance and prolonged lifespan

• Bright body with ground flutes offers excellent precision when cutting

• 118° for excellent positional accuracy

Standards

• Manufactured to BS 328, DIN 338

Notes

Suitable for the machining of:

• Steel and cast steel (alloyed and non-alloyed)

• Grey cast iron, graphite and malleable cast iron

• Available in sizes 1.0mm - 16mm

Features and Benefits

• Hardy TiN tipped coating for optimal performance and prolonged lifespan

• Bright body with ground flutes offers excellent precision when cutting

• 118° for excellent positional accuracy

Standards

• Manufactured to BS 328, DIN 338

Notes

Suitable for the machining of:

• Steel and cast steel (alloyed and non-alloyed)

• Grey cast iron, graphite and malleable cast iron

• Available in sizes 1.0mm - 16mm

Swisstech 36, End Mill, Regular, Threaded Shank, 6mm, Cobalt High Speed Steel, Uncoated

Series 36 - Regular Series

Dimensions to DIN 844. Centre cutting. Threaded shank to DIN 1835D. Shank cutting diameter to +0.04 -0.0.

Uncoated (for general production machining)

TiCN Coated (extends cutter life and improves work material surface finish)

TiALN Coated (dissipates and resists heat, reduces surface friction coupled with high surface hardness).

Dimensions to DIN 844. Centre cutting. Threaded shank to DIN 1835D. Shank cutting diameter to +0.04 -0.0.

Uncoated (for general production machining)

TiCN Coated (extends cutter life and improves work material surface finish)

TiALN Coated (dissipates and resists heat, reduces surface friction coupled with high surface hardness).

Kennedy Masonry Drill Bit, 6mm x 150mm, Straight

Tungsten carbide tipped with roll forged flutes.

Features and Benefits

• Hard tungsten carbide tips for clean and accurate holes

• Universal compatibility - fits most tools

• Shank type: Straight

• Flute construction: Roll forged

Typical Applications

• A general purpose mortar and masonry drill bit suitable for workshop and maintenance

Standards

• Manufactured to DIN 8039

Features and Benefits

• Hard tungsten carbide tips for clean and accurate holes

• Universal compatibility - fits most tools

• Shank type: Straight

• Flute construction: Roll forged

Typical Applications

• A general purpose mortar and masonry drill bit suitable for workshop and maintenance

Standards

• Manufactured to DIN 8039

Sherwood Jobber Drill, 14mm, Normal Helix, High Speed Steel, Black Oxide

The J100 Series are general purpose HSS straight shank drills with a black oxide finish. Ideal for applications involving steel (including cast steel) cast iron (including malleable cast iron) as well as nickel, brass aluminium alloys and graphite. Their 118° point allows for precise hole alignment and reliable cutting performance whilst the black oxide coating helps reduce heat by retaining coolant on the tool surface. The coating also helps reduce the risk of the tool staining.

Features and Benefits

• High speed steel construction for increased tool durability

• Point angle of 118° for precise holemaking and precision cutting

• Black oxide coating helps aid chip flow, reduce heat and prevent staining

• Ideal for applications involving steel, iron, nickel, brass, aluminium alloy and graphite

Typical Applications

• Cutting and drilling

• Ferrous materials

• Steel

• Iron

• Nickel

• Brass

• Aluminium alloy

• Graphite

Notes

• Available in sizes 0.25mm -20.00mm

Standards

• Manufactured to BS 328/DIN338RN

Features and Benefits

• High speed steel construction for increased tool durability

• Point angle of 118° for precise holemaking and precision cutting

• Black oxide coating helps aid chip flow, reduce heat and prevent staining

• Ideal for applications involving steel, iron, nickel, brass, aluminium alloy and graphite

Typical Applications

• Cutting and drilling

• Ferrous materials

• Steel

• Iron

• Nickel

• Brass

• Aluminium alloy

• Graphite

Notes

• Available in sizes 0.25mm -20.00mm

Standards

• Manufactured to BS 328/DIN338RN