Abrasive

Flexovit Cut Off Wheel, 180 x, 1.8 x, 31.75mm, A60, Aluminium Oxide, 69936623127

Non-Reinforced Toolroom Cutting Wheels

Thin slitting discs in aluminium oxide grain for all toolroom cutting-off applications.

Thin slitting discs in aluminium oxide grain for all toolroom cutting-off applications.

Download

Produk Lainnya

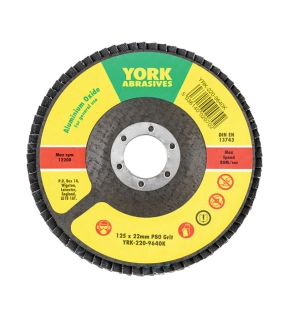

York Flap Disc, 125 x 22.23mm, Conical (Type 29), P80, Aluminium Oxide

Conical flap discs are a high performance alternative to sanding discs where surface finish is important. On light gauge sheet metal, the overlapped abrasive strips slowly wear away revealing fresh abrasive.

Features and Benefits

• The overlap design reduces clogging and ensures the disc always cuts effectively and

• Provides a consistent finish throughout disc life

• No backing pads needed

Notes

• Safe to use at 80m/s on any grinder

Standards

EN12413

Features and Benefits

• The overlap design reduces clogging and ensures the disc always cuts effectively and

• Provides a consistent finish throughout disc life

• No backing pads needed

Notes

• Safe to use at 80m/s on any grinder

Standards

EN12413

York Bob, Cylindrical, Felt, 6 x 14mm, 3mm Shank

Plain End Cylinder (Bob)

York Felt Bobs are made of pure wool in a variety of sizes, shapes. The mandrels are exactly centred for true-running operation. Suitable for product finishing/polishing with finishing/polishing compounds.

York Felt Bobs are made of pure wool in a variety of sizes, shapes. The mandrels are exactly centred for true-running operation. Suitable for product finishing/polishing with finishing/polishing compounds.

Kennedy Coated Roll, Economy, 38mm x 50m, Aluminium Oxide, P150

38mm x 50m Rolls.

Blue twill economy emery is "glue bonded" to a very flexible J-weight blue twill cloth. Suitable for general purpose, light duty workshop use.

Blue twill economy emery is "glue bonded" to a very flexible J-weight blue twill cloth. Suitable for general purpose, light duty workshop use.

York Coated Sheet, 230 x 280mm, Silicon Carbide, P240, Wet & Dry

These abrasive paper sheets have silicon carbide, waterproof-resin bonded to paper. They are suitable for wet and dry use, making them versatile. There are a variety of grades in this range of sheets.

Features and Benefits

• Silicon carbide

• Ideal for wet and dry use

• Waterproof resin

Typical Applications

• Polishing

• Finishing

• Metals

• Plastics

• Paintwork

• Ceramics

Features and Benefits

• Silicon carbide

• Ideal for wet and dry use

• Waterproof resin

Typical Applications

• Polishing

• Finishing

• Metals

• Plastics

• Paintwork

• Ceramics