Tools & Chemicals

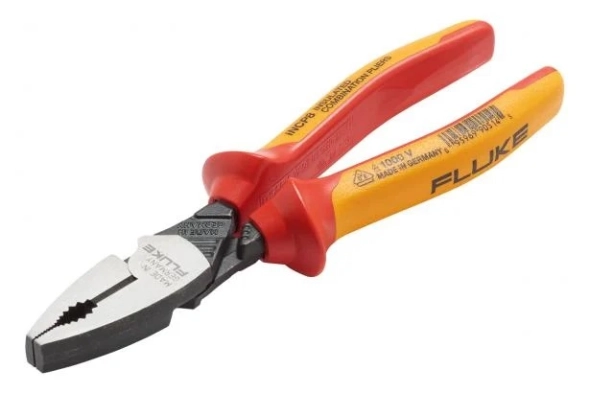

Fluke insulated combination pliers

- Heavy duty, 8-inch insulated combination pliers

- Certified to 1000 V AC, 1500 V DC

- Aggressive side cutting serrated jaws and 4-point gripping hole

- Certified to 1000 V AC, 1500 V DC

- Aggressive side cutting serrated jaws and 4-point gripping hole

Download

Products Lainnya

Kennedy Double End, Open Ended Spanner, 41 x 46mm, Metric

Supplied in metric sizes, this range of double-ended spanners is highly versatile. Constructed from chrome vanadium steel* with a satin finish body and highly polished heads, the product is completed by a 15° offset angled head. Available in multiple sizes to allow you to select the product best suited to your application.

Features and Benefits

• Manufactured from chrome vanadium steel* which is highly robust and durable

• Double-ended design gives double the tool life and use

• Highly polished heads repel dirt and grime and make for easier cleaning

• 15° offset angled head allows for access in restricted areas and makes turning easier

• Available in an array of sizes to suit your specific application

Typical Applications

• Plumbing

• DIY

• Automotive

• Engineering

Standards

• ASME B107: Sizes 36 x 41mm to 46mm x 50mm

• DIN 3310: Sizes 4 x 5mm to 32 x 36mm

Notes

• *36 x 41, 41 x 46, 46 x 50mm are made from drop forged carbon steel

Features and Benefits

• Manufactured from chrome vanadium steel* which is highly robust and durable

• Double-ended design gives double the tool life and use

• Highly polished heads repel dirt and grime and make for easier cleaning

• 15° offset angled head allows for access in restricted areas and makes turning easier

• Available in an array of sizes to suit your specific application

Typical Applications

• Plumbing

• DIY

• Automotive

• Engineering

Standards

• ASME B107: Sizes 36 x 41mm to 46mm x 50mm

• DIN 3310: Sizes 4 x 5mm to 32 x 36mm

Notes

• *36 x 41, 41 x 46, 46 x 50mm are made from drop forged carbon steel

Kennedy-Pro Tool Bag, 600 Denier Polyester, (L) 445mm x (W) 280mm x (H) 305mm

With an attractive black and red design, this 600 denier fabric tool bag is an efficient way to transport your tools to various job sites. With a padded, adjustable shoulder strap and handles, it's lightweight and comfortable as well as robust. Possesses a total of 11 internal pockets and 17 external pockets, coupled with a large internal compartment. The bag closes via a heavy-duty zip.

Features and Benefits

• Manufactured from 600 denier polyester making it durable and resistant to everyday wear and tear

• Has padded handles and shoulder strap to ensure comfort when transporting even a full bag

• Possesses a heavy duty zip to secure your tools when not in use

• Boasts a total of 28 pockets and compartments for ample space for your most used hand tools and components

Typical Applications

• Ideal for use on site or when moving between locations due to its transportable nature and hard wearing construction

Features and Benefits

• Manufactured from 600 denier polyester making it durable and resistant to everyday wear and tear

• Has padded handles and shoulder strap to ensure comfort when transporting even a full bag

• Possesses a heavy duty zip to secure your tools when not in use

• Boasts a total of 28 pockets and compartments for ample space for your most used hand tools and components

Typical Applications

• Ideal for use on site or when moving between locations due to its transportable nature and hard wearing construction

Kennedy Ball Pein Hammer, 2lb, Fibreglass Shaft, Anti-vibration

Manufactured from, drop forged steel with a red fibreglass handle, this range of ball pein hammers are designed for strength and user comfort. With a black textured slip resistant rubber grip and a shaft and grip that combine to dampen the impact transmitted through to the user's hand and wrist. The overall product is one that aims to reduce operator fatigue and the risk of RSI (Repetitive Strain Injury). Available in a range of sizes and specifications.

Features and Benefits

• Fibreglass handle has a textured, slip resistant rubber grip to allow for easy use

• Design allows for anti-vibration to deliver more solid blows

• Head is constructed from drop forged steel to bolster strength and durability

• In an attractive black and red colour to suit all workplaces

• Available in varying sizes and specifications to allow you to select the product that best suits your needs

Typical Applications

• Ideal for industrial use by professionals such as construction workers, builders and DIY enthusiasts

Features and Benefits

• Fibreglass handle has a textured, slip resistant rubber grip to allow for easy use

• Design allows for anti-vibration to deliver more solid blows

• Head is constructed from drop forged steel to bolster strength and durability

• In an attractive black and red colour to suit all workplaces

• Available in varying sizes and specifications to allow you to select the product that best suits your needs

Typical Applications

• Ideal for industrial use by professionals such as construction workers, builders and DIY enthusiasts

Kennedy Ball Pein Hammer, 1-1/2lb, Wood Shaft, Polished Face

This range of ball pein hammers have been manufactured from high-grade drop forged steel that has been fully heat-treated. Ideal for use with cold chisels, punches, rivets and for the shaping of metal. With fine grain, forged steel head, hardened and tempered with polished faces complete by a hardwood shaft. Available in varying sizes to suit your needs.

Features and Benefits

• Manufactured from drop forged high grade steel making for a robust product

• Head is heat treated for durability

• Solid wooden handle for bolstered grip and control when wielding

Typical Applications

• Ideal for use with cold chisels, punches, rivets and for the shaping of metals

Features and Benefits

• Manufactured from drop forged high grade steel making for a robust product

• Head is heat treated for durability

• Solid wooden handle for bolstered grip and control when wielding

Typical Applications

• Ideal for use with cold chisels, punches, rivets and for the shaping of metals