Measuring Tools

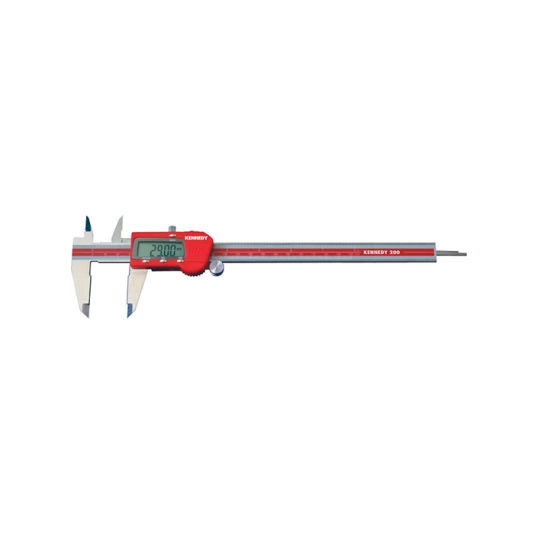

Kennedy 8"/200mm DIGITAL ABS ELECTRONIC CALIPER

Modern design with a knurled thumb wheel for easy use when taking internal and external depth and step measurements.

Dual readout giving instant inch/metric conversion at the touch of a button.

Zero reset at any point, large clear display, error-free operation, fast response speed. Non-output type.

Resolution: 0.01mm/0.0005".

Extra batteries available - Order Code EDI -904-4000K.

Dual readout giving instant inch/metric conversion at the touch of a button.

Zero reset at any point, large clear display, error-free operation, fast response speed. Non-output type.

Resolution: 0.01mm/0.0005".

Extra batteries available - Order Code EDI -904-4000K.

Download

Products Lainnya

Fluke TiS20+ / TiS20+ MAX Thermal Imaging Camera

Save time with precise infrared levels and analysis

Whether you're on the roof checking heating, ventilation and air conditioning, deep in the factory checking motors, or if you've locked down the electrical panels, you rely on a tool that has the power and features to do the job quickly.

The Fluke TiS20+ and TiS20+ MAX handheld thermal cameras put the power of thermal imaging at your fingertips. Designed to make your job faster and easier, this thermal imager is the perfect tool for:

- Commercial electrician

- Heating, ventilation, air conditioning and refrigeration technician

- Maintenance technician

Get context with a combination of visual light and infrared images

In thermography, context is important. Let Fluke IR-Fusion™ make your job easier by using a thermal image superimposed on a visual light image to provide a complete picture of where an issue is a problem before it actually becomes a problem. Just slide your finger across the screen to adjust the infrared level. Whether you're experiencing an uneven load on your switchgear or checking your ventilation system, the Fluke TiS20+ helps you quickly detect issues.

You work hard all day, your tools too

You must not let your thermal imager be damaged by the environment. You can sleep well at night knowing that your camera will stand up to whatever the day throws at it.

- 2 meter high drop test

- Waterproof (IP54)

- Dustproof (IP54)

Stop sorting, start analyzing with Fluke Connect Asset Tagging

Avoid long hours on the computer setting up your thermal images, let Asset Tagging do all the work for you. No more dragging and dropping or renaming files in the office, just scan the QR code on your assets, take thermal images and they are automatically sorted by assets. Start spending your time analyzing images and creating reports instead of sorting files one by one.

Longest battery life in a Fluke thermal camera

The TiS20+ and TiS20+ MAX work non-stop, with a battery life of over 5 hours of continuous use making it the longest battery life in a Fluke thermal camera. Save battery power for multiple inspection points with sleep mode. Just press the power button once and you are ready to go.

Whether you're on the roof checking heating, ventilation and air conditioning, deep in the factory checking motors, or if you've locked down the electrical panels, you rely on a tool that has the power and features to do the job quickly.

The Fluke TiS20+ and TiS20+ MAX handheld thermal cameras put the power of thermal imaging at your fingertips. Designed to make your job faster and easier, this thermal imager is the perfect tool for:

- Commercial electrician

- Heating, ventilation, air conditioning and refrigeration technician

- Maintenance technician

Get context with a combination of visual light and infrared images

In thermography, context is important. Let Fluke IR-Fusion™ make your job easier by using a thermal image superimposed on a visual light image to provide a complete picture of where an issue is a problem before it actually becomes a problem. Just slide your finger across the screen to adjust the infrared level. Whether you're experiencing an uneven load on your switchgear or checking your ventilation system, the Fluke TiS20+ helps you quickly detect issues.

You work hard all day, your tools too

You must not let your thermal imager be damaged by the environment. You can sleep well at night knowing that your camera will stand up to whatever the day throws at it.

- 2 meter high drop test

- Waterproof (IP54)

- Dustproof (IP54)

Stop sorting, start analyzing with Fluke Connect Asset Tagging

Avoid long hours on the computer setting up your thermal images, let Asset Tagging do all the work for you. No more dragging and dropping or renaming files in the office, just scan the QR code on your assets, take thermal images and they are automatically sorted by assets. Start spending your time analyzing images and creating reports instead of sorting files one by one.

Longest battery life in a Fluke thermal camera

The TiS20+ and TiS20+ MAX work non-stop, with a battery life of over 5 hours of continuous use making it the longest battery life in a Fluke thermal camera. Save battery power for multiple inspection points with sleep mode. Just press the power button once and you are ready to go.

Kennedy 8"/200mm DIGITAL ABS ELECTRONIC CALIPER

Modern design with a knurled thumb wheel for easy use when taking internal and external depth and step measurements.

Dual readout giving instant inch/metric conversion at the touch of a button.

Zero reset at any point, large clear display, error-free operation, fast response speed. Non-output type.

Resolution: 0.01mm/0.0005".

Extra batteries available - Order Code EDI -904-4000K.

Dual readout giving instant inch/metric conversion at the touch of a button.

Zero reset at any point, large clear display, error-free operation, fast response speed. Non-output type.

Resolution: 0.01mm/0.0005".

Extra batteries available - Order Code EDI -904-4000K.

Fluke 568 Contact & Infrared Temp Gun

Two-in-one contact and IR thermometer with innovative dot matrix display.

With a simple interface, a 3-button on-screen menu (in 6 languages) the Fluke 568 and 566 digital laser thermometers make even complex measurements easy. Quickly navigate advanced features to adjust sensitivity, start data logging, or activate and deactivate alarms - with just a few button presses.

With a rugged, easy-to-use ergonomic design, the Fluke 568 and 566 two-in-one contact and non-contact thermometers can handle tough industrial, electrical, and mechanical environments. These tools outperform any other IR thermometer (or pyrometer), helping you work more efficiently in a wider range of applications.

With a simple interface, a 3-button on-screen menu (in 6 languages) the Fluke 568 and 566 digital laser thermometers make even complex measurements easy. Quickly navigate advanced features to adjust sensitivity, start data logging, or activate and deactivate alarms - with just a few button presses.

With a rugged, easy-to-use ergonomic design, the Fluke 568 and 566 two-in-one contact and non-contact thermometers can handle tough industrial, electrical, and mechanical environments. These tools outperform any other IR thermometer (or pyrometer), helping you work more efficiently in a wider range of applications.

Fluke 1760TR Three-Phase Power Quality Recorder

The Fluke 1760 Three-Phase Power Quality Recorder complies strictly with IEC 61000-4-30 Class-A, for advanced power quality analysis and consistent conformity testing. Designed for the analysis of utility and industrial power distribution systems, in medium and low voltage networks, these power quality monitors give customers the flexibility to customize threshold selection, algorithms and measurements. The Fluke 1760 power recorder records the most thorough detail for user-selected parameters.

Usage

Detailed fault analysis – Performs high-speed transient analysis and finds root causes of equipment malfunctions for later mitigation of malfunctions and predictive maintenance. The fast transient option, with a measuring range of 6,000 V, makes it possible to record very short impulses such as lightning strikes.

Class-A Quality of Service Compliance – Validates the quality of incoming power at the service gateway. Thanks to Class A conformance, the Fluke 1760 allows unquestioned verification.

Correlation of events at multiple locations – Using GPS time synchronization, users can quickly detect where a fault first occurred, both inside and outside the facility.

Galvanic separation and DC coupling – Allows complete measurement of dissimilar power systems. For example, troubleshooting a UPS system by simultaneously recording battery voltage and power output.

Power quality and power load monitoring – Assess baseline power quality to validate compatibility with critical systems prior to installation and verify electrical system capacity before increasing loads.

Usage

Detailed fault analysis – Performs high-speed transient analysis and finds root causes of equipment malfunctions for later mitigation of malfunctions and predictive maintenance. The fast transient option, with a measuring range of 6,000 V, makes it possible to record very short impulses such as lightning strikes.

Class-A Quality of Service Compliance – Validates the quality of incoming power at the service gateway. Thanks to Class A conformance, the Fluke 1760 allows unquestioned verification.

Correlation of events at multiple locations – Using GPS time synchronization, users can quickly detect where a fault first occurred, both inside and outside the facility.

Galvanic separation and DC coupling – Allows complete measurement of dissimilar power systems. For example, troubleshooting a UPS system by simultaneously recording battery voltage and power output.

Power quality and power load monitoring – Assess baseline power quality to validate compatibility with critical systems prior to installation and verify electrical system capacity before increasing loads.