Measuring Tools

Fluke 1732/INTL Three Phase Power Energy Monitor & Logger, Battery-Powered

Fluke 1732 3 phase Electrical Energy Logger

Energy logging is now within your reach—discover where you’re wasting energy, optimize your facility’s energy use and reduce your bill. The new Fluke 1732 Three-Phase Electrical Energy loggers introduce a new simplicity to discovering sources of electrical energy waste. Discover when and where energy in your facility is being consumed; from the service entrance to individual circuits.

Profiling energy usage across your facility helps you identify opportunities for energy savings, and provides you with the data you need to act on them. The new Energy Analyse software package allows you to compare multiple data points over time to build a complete picture of energy usage, which is the first step to reduce the cost of your energy bill.

Features and Benefits

• Key Measurements: Automatically capture and log voltage, current, power, power factor, energy and associated values

• Bright, colour touch screen, perform convenient in-the-field analysis and data checks with full graphical display

• Comprehensive Logging: More than 20 separate logging sessions can be stored on the instruments.

• Optimised User Interface: Quick, guided, graphical setup ensures that you are capturing the right data every time, and the intelligent verification function indicates that correct connections have been made, reducing user uncertainty

• Convenient Instrument Powering: Power instrument directly from the measured circuit

• Highest safety rating in the industry: 600 V CAT IV/1000 V CAT III rated for use at the service entrance and downstream

• Measure all 3 phases with included 3 flexible current probes

• Complete “in-the-field"" setup through the front panel or Fluke Connect: No need to return to the workshop for download and setup or to take a computer to the electrical panel

• Fluke Connect® compatible: View data locally on the instrument, via Fluke Connect mobile app and desktop software or through your facilities’ WiFi infrastructure

• Energy Analyse Plus application software: Download and analyse every detail of energy consumption with our automated reporting

Fluke 1732/B Contents

Energy logger, basic version (excludes current probes), power supply, voltage test leads, alligator clips (4x), soft case, energy analyse plus software, line cords, colour coding set and documentation on USB flash drive

Fluke 1732/INTL Contents

Energy logger, International version (includes current probes), power supply, voltage test leads, alligator clips (4x), 12 in 1500 A flexible current probe (3x), soft case, energy analyse plus software, line cords, colour coding set and documentation on USB flash drive

Note:

CRITICAL SAFETY ALERT - PLEASE READ! Fluke has determined that certain improper use of the test lead set, 3PHVL-1730 or 3PHVL-1735-5M 'Voltage Test Lead, 3-phase + N', included with the 173x Series, 174x Series Power Quality Loggers and 3540FC Power Monitor, may potentially expose users to hazardous conditions, posing the risk of serious personal injury or death.

Energy logging is now within your reach—discover where you’re wasting energy, optimize your facility’s energy use and reduce your bill. The new Fluke 1732 Three-Phase Electrical Energy loggers introduce a new simplicity to discovering sources of electrical energy waste. Discover when and where energy in your facility is being consumed; from the service entrance to individual circuits.

Profiling energy usage across your facility helps you identify opportunities for energy savings, and provides you with the data you need to act on them. The new Energy Analyse software package allows you to compare multiple data points over time to build a complete picture of energy usage, which is the first step to reduce the cost of your energy bill.

Features and Benefits

• Key Measurements: Automatically capture and log voltage, current, power, power factor, energy and associated values

• Bright, colour touch screen, perform convenient in-the-field analysis and data checks with full graphical display

• Comprehensive Logging: More than 20 separate logging sessions can be stored on the instruments.

• Optimised User Interface: Quick, guided, graphical setup ensures that you are capturing the right data every time, and the intelligent verification function indicates that correct connections have been made, reducing user uncertainty

• Convenient Instrument Powering: Power instrument directly from the measured circuit

• Highest safety rating in the industry: 600 V CAT IV/1000 V CAT III rated for use at the service entrance and downstream

• Measure all 3 phases with included 3 flexible current probes

• Complete “in-the-field"" setup through the front panel or Fluke Connect: No need to return to the workshop for download and setup or to take a computer to the electrical panel

• Fluke Connect® compatible: View data locally on the instrument, via Fluke Connect mobile app and desktop software or through your facilities’ WiFi infrastructure

• Energy Analyse Plus application software: Download and analyse every detail of energy consumption with our automated reporting

Fluke 1732/B Contents

Energy logger, basic version (excludes current probes), power supply, voltage test leads, alligator clips (4x), soft case, energy analyse plus software, line cords, colour coding set and documentation on USB flash drive

Fluke 1732/INTL Contents

Energy logger, International version (includes current probes), power supply, voltage test leads, alligator clips (4x), 12 in 1500 A flexible current probe (3x), soft case, energy analyse plus software, line cords, colour coding set and documentation on USB flash drive

Note:

CRITICAL SAFETY ALERT - PLEASE READ! Fluke has determined that certain improper use of the test lead set, 3PHVL-1730 or 3PHVL-1735-5M 'Voltage Test Lead, 3-phase + N', included with the 173x Series, 174x Series Power Quality Loggers and 3540FC Power Monitor, may potentially expose users to hazardous conditions, posing the risk of serious personal injury or death.

Download

Products Lainnya

Fluke 9170, 9171, 9172, & 9173 Metrology Well Calibrators

Accurate enough for lab use, and rugged and portable enough to take anywhere

• Best-performing industrial heat sources (accuracy, stability, uniformity) in the world

• Immersion depth to 203 mm (8 in)

• Optional ITS-90 reference input reads PRTs to ±0.006 °C

• Temperature range from –45 °C to 700 °C

Every once in a while, a new product comes around that changes the rules. It happened when we introduced handheld dry-wells. It happened when we introduced Micro-Baths. Now we’ve combined bath-level performance with dry-well functionality and legitimate reference thermometry to create Metrology Wells.

With groundbreaking new proprietary electronics from Fluke Calibration's (patents pending), Metrology Wells let you bring lab-quality performance into whatever field environment you might work in. New analog and digital control techniques provide stability as good as ±0.005 °C. And with dual-zone control, axial (or “vertical") uniformity is as good as ±0.02 °C over a 60 mm (2.36 in) zone. (That’s 60 mm!) Such performance doesn’t exist anywhere else outside of fluid baths.

In short, there are six critical components of performance in an industrial heat source (which the European metrology community explains, for example, in the document EA-10/13): calibrated display accuracy, stability, axial (vertical) uniformity, radial (well-to-well) uniformity, impact from loading, and hysteresis. We added a seventh in the form of a legitimate reference thermometer input and created an entirely new product category: Metrology Wells.

(By the way, Metrology Wells are the only products on the market supported by published specifications addressing every performance category in the EA-10/13. Our specs aren’t just hopes or guidelines. They apply to every Metrology Well we sell.)

• Best-performing industrial heat sources (accuracy, stability, uniformity) in the world

• Immersion depth to 203 mm (8 in)

• Optional ITS-90 reference input reads PRTs to ±0.006 °C

• Temperature range from –45 °C to 700 °C

Every once in a while, a new product comes around that changes the rules. It happened when we introduced handheld dry-wells. It happened when we introduced Micro-Baths. Now we’ve combined bath-level performance with dry-well functionality and legitimate reference thermometry to create Metrology Wells.

With groundbreaking new proprietary electronics from Fluke Calibration's (patents pending), Metrology Wells let you bring lab-quality performance into whatever field environment you might work in. New analog and digital control techniques provide stability as good as ±0.005 °C. And with dual-zone control, axial (or “vertical") uniformity is as good as ±0.02 °C over a 60 mm (2.36 in) zone. (That’s 60 mm!) Such performance doesn’t exist anywhere else outside of fluid baths.

In short, there are six critical components of performance in an industrial heat source (which the European metrology community explains, for example, in the document EA-10/13): calibrated display accuracy, stability, axial (vertical) uniformity, radial (well-to-well) uniformity, impact from loading, and hysteresis. We added a seventh in the form of a legitimate reference thermometer input and created an entirely new product category: Metrology Wells.

(By the way, Metrology Wells are the only products on the market supported by published specifications addressing every performance category in the EA-10/13. Our specs aren’t just hopes or guidelines. They apply to every Metrology Well we sell.)

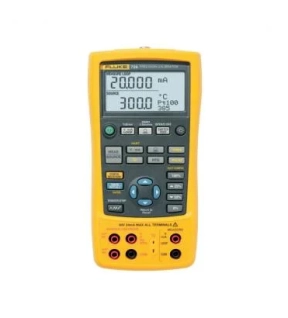

Fluke 726 Precision Multifunction Calibrators

Process calibration designed specifically for process industries

The Fluke 726 is a precise and powerful, yet easy-to-use, field calibrator. It features broad workload coverage, calibration power, and unsurpassed accuracy needed by process professionals. It measures and sources almost all process parameters to calibrate almost anything. Use it to test sensors and valves, and to test and calibrate transmitters. The 726 interprets results without the help of a calculator and stores measurement data for later analysis.

Measurement capabilities

This precision multifunction calibrator measures volts, mA, pressure, RTDs, thermocouples, frequency, and resistance to test sensors and transmitters. The 726 also sources and simulates volts, mA, thermocouples, RTDs, frequency to calibrate transmitters. Measures and/or sources pressure using when paired with any of the 50 Fluke 750P series Pressure Modules to test and calibrate pressure transmitters and other devices. The 726 can also:

- Source mA with simultaneous pressure measurement to conduct valve and I/P test

- Conduct enhanced flowmeter testing with frequency totalizer and frequency pulse train source mode

Designed for ease of use

The 726 has built-in features that make it easier to use in nearly any measurement situation. From its ability to store frequently used test setups, to programming custom RTD probe calibration constants for enhanced temperature measurement, or the integrated voltage input protection design that improves reliability, the 726 is built to perform. The use of two separate channels even allows you to measure, source, or view process signals simultaneously. The backlit display provides better visibility in low-light conditions, and the standard 3-year warranty provides extra confidence that the 726 will be there when you need it to be.

You can also use the 726 to:

- Capture the set, reset, and deadband of a pressure switch with the integrated switch test

- Calculate the transmitter error % to interpret calibration results without the use of a calculator

- Perform fast linearity tests with the auto-step and auto-ramp features

- Power a transmitter during test using 24 V loop supply and simultaneous mA measurement

The Fluke 726 is a precise and powerful, yet easy-to-use, field calibrator. It features broad workload coverage, calibration power, and unsurpassed accuracy needed by process professionals. It measures and sources almost all process parameters to calibrate almost anything. Use it to test sensors and valves, and to test and calibrate transmitters. The 726 interprets results without the help of a calculator and stores measurement data for later analysis.

Measurement capabilities

This precision multifunction calibrator measures volts, mA, pressure, RTDs, thermocouples, frequency, and resistance to test sensors and transmitters. The 726 also sources and simulates volts, mA, thermocouples, RTDs, frequency to calibrate transmitters. Measures and/or sources pressure using when paired with any of the 50 Fluke 750P series Pressure Modules to test and calibrate pressure transmitters and other devices. The 726 can also:

- Source mA with simultaneous pressure measurement to conduct valve and I/P test

- Conduct enhanced flowmeter testing with frequency totalizer and frequency pulse train source mode

Designed for ease of use

The 726 has built-in features that make it easier to use in nearly any measurement situation. From its ability to store frequently used test setups, to programming custom RTD probe calibration constants for enhanced temperature measurement, or the integrated voltage input protection design that improves reliability, the 726 is built to perform. The use of two separate channels even allows you to measure, source, or view process signals simultaneously. The backlit display provides better visibility in low-light conditions, and the standard 3-year warranty provides extra confidence that the 726 will be there when you need it to be.

You can also use the 726 to:

- Capture the set, reset, and deadband of a pressure switch with the integrated switch test

- Calculate the transmitter error % to interpret calibration results without the use of a calculator

- Perform fast linearity tests with the auto-step and auto-ramp features

- Power a transmitter during test using 24 V loop supply and simultaneous mA measurement

Fluke 4180, 4181 Precision Infrared Calibrators

Accuracy and traceability for infrared measurements

Now it’s easy to increase your IR temperature measurement accuracy with the new 4180, 4181 Precision Infrared Calibrators from Fluke Calibration. These infrared temperature calibrators give more consistent, accurate and reliable calibrations because emissivity is radiometrically calibrated, and the target size minimizes size of source effect errors. In addition, these infrared calibrators simplify calibration because they uniquely compensate for errors caused by thermometer emissivity settings.

New accredited performance for point-and-shoot calibrations

• Calibrated radiometrically for meaningful, consistent results.

• Accredited calibration included

• Accurate, reliable performance from –15 °C to 500 °C

• Large target size of 152 mm (6 in) is required for calibrating most thermometers.

• Light instrument weight of 8.6 kg (19 lbs) makes it easy to lift and carry.

• Intuitive, easy-to-read display that indicates when temperature is stable.

Now it’s easy to increase your IR temperature measurement accuracy with the new 4180, 4181 Precision Infrared Calibrators from Fluke Calibration. These infrared temperature calibrators give more consistent, accurate and reliable calibrations because emissivity is radiometrically calibrated, and the target size minimizes size of source effect errors. In addition, these infrared calibrators simplify calibration because they uniquely compensate for errors caused by thermometer emissivity settings.

New accredited performance for point-and-shoot calibrations

• Calibrated radiometrically for meaningful, consistent results.

• Accredited calibration included

• Accurate, reliable performance from –15 °C to 500 °C

• Large target size of 152 mm (6 in) is required for calibrating most thermometers.

• Light instrument weight of 8.6 kg (19 lbs) makes it easy to lift and carry.

• Intuitive, easy-to-read display that indicates when temperature is stable.

Kennedy Double Ended Imperial & Metric Feeler Gauge

Hardened and polished taper blades enclosed in a steel case. Blades are clearly marked for easy reading and are manufactured to DIN 2275.

Features and Benefits

• Hardened and polished blades for increased tool life

• Blades are clearly marked for easy readings

• Supplied in a steel case for easy storage and portability

Standards

• DIN 2275

Notes

• Blade length: (75mm/3")

• Metric: (0.05mm - 0.5mm)

• Inch: (0.0015" - 0.025")

Features and Benefits

• Hardened and polished blades for increased tool life

• Blades are clearly marked for easy readings

• Supplied in a steel case for easy storage and portability

Standards

• DIN 2275

Notes

• Blade length: (75mm/3")

• Metric: (0.05mm - 0.5mm)

• Inch: (0.0015" - 0.025")