Cutting Tools

Sherwood L100, Long Series Drill, 3mm, Long Series, Straight Shank, High Speed Steel, Steam Tempered

Series L100 HSS straight shank long series drills are excellent general purpose drills which are designed to drill steels with tensile strength up to 1,000N/mm2, cast steel, grey cast iron, malleable cast iron, nickel brass and graphite.

Features and Benefits

• Manufactured from HSS for improved toughness

• Black oxide coating for greater heat and wear resistance

• Ideal for general purpose drilling

Typical Applications

• Drilling

• Steels

• Grey cast iron

• Malleable cast iron

• Nickel brass

• Graphite

Standards

• Manufactured to BS 328; Part 1: 1986, DIN 340 RN, ISO 494.

Features and Benefits

• Manufactured from HSS for improved toughness

• Black oxide coating for greater heat and wear resistance

• Ideal for general purpose drilling

Typical Applications

• Drilling

• Steels

• Grey cast iron

• Malleable cast iron

• Nickel brass

• Graphite

Standards

• Manufactured to BS 328; Part 1: 1986, DIN 340 RN, ISO 494.

Download

Products Lainnya

Atlas Workhokders SC105225 55x25x12mm M10 STEP CLAMP

Material: Medium Carbon Steel.

Hardness: HRC 32 - 38.

Surface Finish: Black Oxide.

Hardness: HRC 32 - 38.

Surface Finish: Black Oxide.

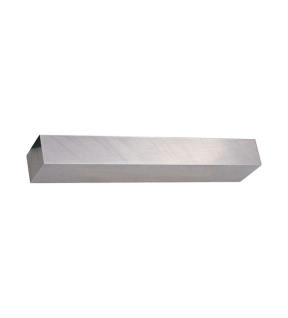

Kennedy Toolbit, 4in. x 1/4in., Square, Uncoated

HSS Square Inch.

Cut faster, 'stand up' longer and reduce costs. Square and rectangular toolbits supplied with 15° bevelled ends. Parting-off blades supplied with 2° side taper, 10° bevel (top and bottom).

Cut faster, 'stand up' longer and reduce costs. Square and rectangular toolbits supplied with 15° bevelled ends. Parting-off blades supplied with 2° side taper, 10° bevel (top and bottom).

Yamaloy CCMT 060204-PM, Turning Insert, Grade QX5030, Carbide, 80° Rhombic

CCMT Turning Inserts

80° Rhombic Insert

Insert Grade QX5030

(ISO P20-P40 M20-M30) CVD Coated. - Medium / rough turning and intermediate cutting of steel / stainless steel. Combination of toughest substrate and alumina coating (MT-TiCN + TiC + AL2O3 + TiN) having superior chipping resistance provide wide coverage.

Chip Breaker: PM. Application: Med Cut.

80° Rhombic Insert

Insert Grade QX5030

(ISO P20-P40 M20-M30) CVD Coated. - Medium / rough turning and intermediate cutting of steel / stainless steel. Combination of toughest substrate and alumina coating (MT-TiCN + TiC + AL2O3 + TiN) having superior chipping resistance provide wide coverage.

Chip Breaker: PM. Application: Med Cut.

Kennedy Countersink, 5.0 - 10.0mm, Straight Shank, 1 fl, 90°, Cobalt High Speed Steel

Manufactured from M35 HSS and used for the deburring and chamfering of most metals and plastics. Features straight shanks and manufactured to BS 328 : Part 5 : 1983.

• Single hole head with nclusive angle of 90° for excellent cutting performance

• Manufactured from M35 HSS for increased toughness

• Uncoated with good heat and wear resistance

Typical Applications

•Countersinking

Standards

• Manufactured to BS 328 : Part 5 : 1983

• Single hole head with nclusive angle of 90° for excellent cutting performance

• Manufactured from M35 HSS for increased toughness

• Uncoated with good heat and wear resistance

Typical Applications

•Countersinking

Standards

• Manufactured to BS 328 : Part 5 : 1983