Cutting Tools

Yamaloy CCGT 060204-PF, Turning Insert, Grade QX520, Carbide, 80° Rhombic

CCGT Turning Inserts

80° Rhombic Insert

Insert Grade QX520

(ISO P10-P35 M10-M30 K10-K30) Coated. An excellent general purpose grade for medium roughing on Steels, Stainless and Cast Irons.

Chip Breaker: PF. Application: Finish.

80° Rhombic Insert

Insert Grade QX520

(ISO P10-P35 M10-M30 K10-K30) Coated. An excellent general purpose grade for medium roughing on Steels, Stainless and Cast Irons.

Chip Breaker: PF. Application: Finish.

Download

Products Lainnya

York A30, Rotary Burr, Diamond, Single Cut, 3mm, Cylindrical

Suitable for precision grinding of carbide, gems, glass, ceramics, tough alloys, cermets, tool steels etc.

Features and Benefits

• Diamond grip mesh is 120/140 for cutting hard substrates

• Ideal for operating speeds of up to 15,000 - 30,000 rpm

• Range of cutting head sizes to suit application

Typical Applications

• Deburring

• Grinding

• Hard substrates

Features and Benefits

• Diamond grip mesh is 120/140 for cutting hard substrates

• Ideal for operating speeds of up to 15,000 - 30,000 rpm

• Range of cutting head sizes to suit application

Typical Applications

• Deburring

• Grinding

• Hard substrates

Kennedy Tap Wrench, Sliding Handle, 6 - 8mm

Manufactured from hardened and tempered steel, with chrome plated high polish finish. Switchable between forward and reverse coupled with the multi-positional sliding T-bar makes this tap wrench ideal for use in confined spaces.

Features and Benefits

• Manufactured from hardened and tempered steel for durability

• High polish finish and chrome plated

• Switchable between forward and reverse

• Ideal for use in confined spaces

Typical Applications

• Tapping

• Hand tapping

Notes

• Individually boxed

Features and Benefits

• Manufactured from hardened and tempered steel for durability

• High polish finish and chrome plated

• Switchable between forward and reverse

• Ideal for use in confined spaces

Typical Applications

• Tapping

• Hand tapping

Notes

• Individually boxed

Yamaloy CNMG 120408-NM6, Turning Insert, Grade QX5030, Carbide, 80° Rhombic

CNMG Turning Inserts

80° Rhombic Insert

Insert Grade QX5030

(ISO P20-P40 M20-M30) CVD Coated. - Medium / rough turning and intermediate cutting of steel / stainless steel. Combination of toughest substrate and alumina coating (MT-TiCN + TiC + AL2O3 + TiN) having superior chipping resistance provide wide coverage.

Chip Breaker: NM6. Application: Med Cut.

80° Rhombic Insert

Insert Grade QX5030

(ISO P20-P40 M20-M30) CVD Coated. - Medium / rough turning and intermediate cutting of steel / stainless steel. Combination of toughest substrate and alumina coating (MT-TiCN + TiC + AL2O3 + TiN) having superior chipping resistance provide wide coverage.

Chip Breaker: NM6. Application: Med Cut.

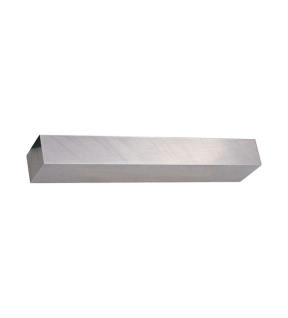

Kennedy Toolbit, 4in. x 1/4in., Square, Uncoated

HSS Square Inch.

Cut faster, 'stand up' longer and reduce costs. Square and rectangular toolbits supplied with 15° bevelled ends. Parting-off blades supplied with 2° side taper, 10° bevel (top and bottom).

Cut faster, 'stand up' longer and reduce costs. Square and rectangular toolbits supplied with 15° bevelled ends. Parting-off blades supplied with 2° side taper, 10° bevel (top and bottom).