Download

Products Lainnya

York 30 Piece Diamond Coated Burr Set with 3mm Shank

Set of various style burrs packaged in a handy pocket 'glasses case' style plastic holder. Ideal for the shop floor workman with various de-burring tasks. Suitable for precision grinding of carbide gems, ceramics, tough alloys, cermets, tool steels etc

Features and Benefits

• Diamond coated for improved hardness

• Excellent performance with precise grinding

Contents

• Assorted sizes of ball shape

• Cylindrical

• Ball nose cylindrical

• Tree shape and conical

Specifications

• Diamond grip mesh is 120/140

• recommended operating speeds 15,000 - 30,000

• Up to 4.5mm diameter

• Overall length 45mm

• 3mm shank

Typical Applications

• Grinding

• Carbide gems

• Glass

• Ceramics

• Tough alloys

• Cermets

• Tool steels

Features and Benefits

• Diamond coated for improved hardness

• Excellent performance with precise grinding

Contents

• Assorted sizes of ball shape

• Cylindrical

• Ball nose cylindrical

• Tree shape and conical

Specifications

• Diamond grip mesh is 120/140

• recommended operating speeds 15,000 - 30,000

• Up to 4.5mm diameter

• Overall length 45mm

• 3mm shank

Typical Applications

• Grinding

• Carbide gems

• Glass

• Ceramics

• Tough alloys

• Cermets

• Tool steels

Kennedy Countersink, 1/2in, Straight Shank, 6 fl, 90°, Cobalt High Speed Steel

Heavy duty construction manufactured from HSS and cobalt for increased hardness and durability with 6 flutes for improved cutting performance and chip control.

Features and Benefits

• HHS-Co construction for improved hardness

• 6 flutes for improved chip control and cutting efficiency

Typical Applications

• Countersinking

Standards

• Manufactured to BS 328:Part 5:1983

Features and Benefits

• HHS-Co construction for improved hardness

• 6 flutes for improved chip control and cutting efficiency

Typical Applications

• Countersinking

Standards

• Manufactured to BS 328:Part 5:1983

Swisstech Jobber Drill, 7mm, High Helix, Cobalt High Speed Steel, TiN

Series 1060 HSS-Co Straight Shank High Helix Jobber Drills

TiN Coated - Metric

Heavy duty drill for stainless steel, heat and acid-resistant steels, short chipping and high strength steels. High heat resistance allows drilling in titanium and titanium alloys. TiN coating provides longer tool life.

Point angle: 130°. Helix angle: high. Web thickness: strengthened. Relief angle: normal.

Tolerance of diameter: h8. Tolerance of shank: f11. Manufactured to DIN 338RN

TiN Coated - Metric

Heavy duty drill for stainless steel, heat and acid-resistant steels, short chipping and high strength steels. High heat resistance allows drilling in titanium and titanium alloys. TiN coating provides longer tool life.

Point angle: 130°. Helix angle: high. Web thickness: strengthened. Relief angle: normal.

Tolerance of diameter: h8. Tolerance of shank: f11. Manufactured to DIN 338RN

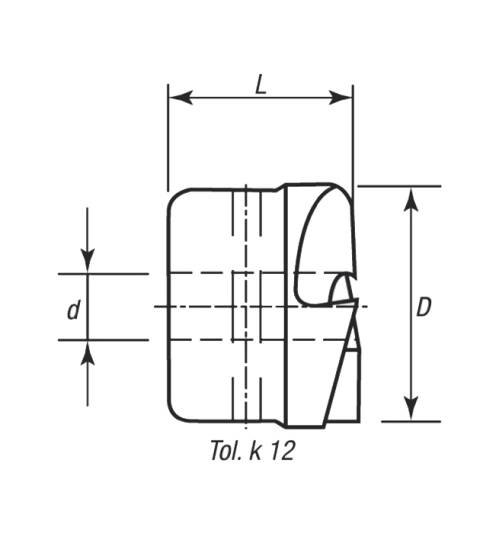

York Carbide Burr, Uncoated, Cut 9 - Chipbreaker, 9.5mm, Cylindrical Plain End

Cut-9 chipbreaker rotary burrs are designed for fast stock removal and improved control for reduced chips for use on hard materials, i.e. steel alloy 50RC, 60RC, carbon and cast iron.

Features and Benefits

• Solid carbide construction

• Enables fast stock removal on hard materials

• Allows for improved control and reduced chips

Typical Applications

• Deburring

• Polishing

• Cast iron

• Cast steel

• Carbon steel

• Alloy steel

• Stainless steel

up to HRC65 hardness.

Notes

• Work piece and tools should always be steady and well supported.

• Carbide burrs are not suitable for 'milling' large amounts of material, they are for light stock removal and high revolutions 'LOW FEED - HIGH SPEED'.

• Always ensure that at least 70% of the shank length is clamped by the collet or chuck of the tool being used.

• Always ensure that the tool is rated to the recommended operating speed of the burr.

Features and Benefits

• Solid carbide construction

• Enables fast stock removal on hard materials

• Allows for improved control and reduced chips

Typical Applications

• Deburring

• Polishing

• Cast iron

• Cast steel

• Carbon steel

• Alloy steel

• Stainless steel

up to HRC65 hardness.

Notes

• Work piece and tools should always be steady and well supported.

• Carbide burrs are not suitable for 'milling' large amounts of material, they are for light stock removal and high revolutions 'LOW FEED - HIGH SPEED'.

• Always ensure that at least 70% of the shank length is clamped by the collet or chuck of the tool being used.

• Always ensure that the tool is rated to the recommended operating speed of the burr.