Pump & Lubricants

Kennedy Suction Gun, 500cc, Metal

With a chrome finish, this oil suction gun is suitable for rapid draining or filling of oil and other non-corrosive liquids. Possessing a working pressure of 90psi/6.2bar and supplied with a flexible 275mm spout.

Features and Benefits

• 500cc capacity allows you to effectively drain or fill without having to release often

• Chrome finish is classic and aesthetically pleasing

• Comes with a 275mm spout for easy draining

Typical Applications

• Engineering

• Automotive

Features and Benefits

• 500cc capacity allows you to effectively drain or fill without having to release often

• Chrome finish is classic and aesthetically pleasing

• Comes with a 275mm spout for easy draining

Typical Applications

• Engineering

• Automotive

Download

Produk Lainnya

Kennedy Hydraulic Nipple, 90°, 1/8" BSP(T), Steel

For use with Kennedy grease guns and all other hydraulic grease equipment.

Kennedy Hydraulic Nipple, Straight, 1/8" BSP(T), Steel

Constructed from steel, these hydraulic grease nipples are designed for use with Kennedy® grease guns and all other hydraulic grease equipment.

Features and Benefits

• Ideal for use on Kennedy® grease guns

• Cost effective way of keeping your grease gun working efficiently

• Manufactured from steel for overall durability

• Available in two sizes to suit your requirements

Typical Applications

• For use with Kennedy grease guns and all other hydraulic grease equipment

Features and Benefits

• Ideal for use on Kennedy® grease guns

• Cost effective way of keeping your grease gun working efficiently

• Manufactured from steel for overall durability

• Available in two sizes to suit your requirements

Typical Applications

• For use with Kennedy grease guns and all other hydraulic grease equipment

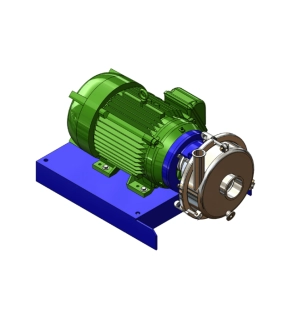

Discflo Sanitary Pumps

Discflo offers two lines of sanitary pumps, the SP Series and MIS Series. Both series meet 3-A sanitary and international hygiene standards and USDA requirements.

They can be supplied in Clean-in-Place or Steam-in-Place versions, and in a variety of metallurgy to meet the user’s requirements.

They can be supplied in Clean-in-Place or Steam-in-Place versions, and in a variety of metallurgy to meet the user’s requirements.

Discflo Glass Lined Pumps

Glass lining is a proven technique for adding a super-durable, smooth, non-stick surface to metal equipment and components.

Discflo glass lined pumps use the dual-coat glass-lining process developed by Vitco, of PA. The glass lining is a mix of fine borosilicate glass, water, and clay, applied to the base metal substrate at high temperature. Vitco’s dual-coat process allows for extra durability and longevity as the base coat forms a strong bond with the base metal and the cover coat provides the non-stick characteristics.

Discflo glass lined pumps use the dual-coat glass-lining process developed by Vitco, of PA. The glass lining is a mix of fine borosilicate glass, water, and clay, applied to the base metal substrate at high temperature. Vitco’s dual-coat process allows for extra durability and longevity as the base coat forms a strong bond with the base metal and the cover coat provides the non-stick characteristics.