Pump & Lubricants

Kennedy Side Lever Grease Gun, 500cc, Bulk/Cartridge/Suction Fill, 6000psi

This side lever grip grease gun is ideal for professionals with its enamel finished steel body and high working pressure of 6000 psi/400 bar. It is suitable for medium/heavy greases.

Features & Benefits

• Enamel finish steel body provides long lasting durability

• Side grip and offset nozzle allows precision on application

• Cartridge, bulk or suction fill allows for flexibility on refills

Features & Benefits

• Enamel finish steel body provides long lasting durability

• Side grip and offset nozzle allows precision on application

• Cartridge, bulk or suction fill allows for flexibility on refills

Download

Produk Lainnya

Kennedy Rotary Pump, 0.25L

RP250

Used for dispensing lubricants and disel, this cast iron pump with a steel suction tube and spout is the easy way to control the flow of said liquids. Suitable for container size of 200 litres, the pump possesses an inlet of 2" BSP and M59 x 5 male thread.

Features and Benefits

• Cast iron pump with steel suction tube and spout making for a hardy product

• Suited for use on a 200 lite capacity barrel

• With a 980mm tube to easily dispense liquids when necessary

Typical Applications

• Suited for controlling the flow of fluids in a 200 litre barrel

Used for dispensing lubricants and disel, this cast iron pump with a steel suction tube and spout is the easy way to control the flow of said liquids. Suitable for container size of 200 litres, the pump possesses an inlet of 2" BSP and M59 x 5 male thread.

Features and Benefits

• Cast iron pump with steel suction tube and spout making for a hardy product

• Suited for use on a 200 lite capacity barrel

• With a 980mm tube to easily dispense liquids when necessary

Typical Applications

• Suited for controlling the flow of fluids in a 200 litre barrel

Kennedy Hydraulic Nipple, Straight, 1/4" BSP(T), Steel

Constructed from steel, these hydraulic grease nipples are designed for use with Kennedy® grease guns and all other hydraulic grease equipment.

Features and Benefits

• Ideal for use on Kennedy® grease guns

• Cost effective way of keeping your grease gun working efficiently

• Manufactured from steel for overall durability

• Available in two sizes to suit your requirements

Typical Applications

• For use with Kennedy grease guns and all other hydraulic grease equipment

Features and Benefits

• Ideal for use on Kennedy® grease guns

• Cost effective way of keeping your grease gun working efficiently

• Manufactured from steel for overall durability

• Available in two sizes to suit your requirements

Typical Applications

• For use with Kennedy grease guns and all other hydraulic grease equipment

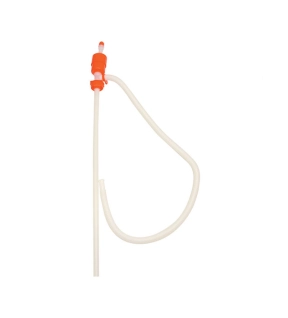

Kennedy SPS/205, Syphon Pump, 205L, Plastic

Available to suit 25 or 205 litre containers, these syphon pumps are an efficient way of controlling and dispensing a host of fluids. Comprised of a flexible plastic outlet and semi-rigid inlet tubes, the hand pumping units incorporate one-way valves. Suited for use with petrol and diesel as well as with non-corrosive liquids. All tubes can be cut to length and are fitted with a threaded bung. Model SPS/25 has a squeeze action and models SPS/205 and SPH/205 have a plunger-type action.

Features and Benefits

• Tubes can be cut to your desired length to meet your requirements

• Suitable for use with petrol, diesel and all non-corrosive liquids

• Available to suit three sized containers

• Flexible nature allows you to manipulate the pump to your desired position

Typical Applications

• Engineering

• Aquatics

• Automotive

Features and Benefits

• Tubes can be cut to your desired length to meet your requirements

• Suitable for use with petrol, diesel and all non-corrosive liquids

• Available to suit three sized containers

• Flexible nature allows you to manipulate the pump to your desired position

Typical Applications

• Engineering

• Aquatics

• Automotive

Kennedy Side Lever Grease Gun, 500cc, Bulk/Cartridge/Suction Fill, 4500psi

These side lever grip grease guns are ideal for professional, extended use, with a sturdy chrome-plated steel body. They can be used with medium/heavy greases. The working pressure is 4500 psi/310 bar.

Features & Benefits

• Chrome-plated steel body provides long lasting durability

• Side grip and offset nozzle allows precision on application

• Cartridge, bulk or suction fill allows for flexibility on refills

Typical Applications

• Applying lubricant to mechanical components

Notes

• Only LG400 has a rubber grip on the handle

Features & Benefits

• Chrome-plated steel body provides long lasting durability

• Side grip and offset nozzle allows precision on application

• Cartridge, bulk or suction fill allows for flexibility on refills

Typical Applications

• Applying lubricant to mechanical components

Notes

• Only LG400 has a rubber grip on the handle