Pump & Lubricants

Kennedy Lever Pump, 0.3L

Suitable for lubricants, diesel and non-corrosive liquids, this lever pump is constructed from a zinc chrome finish steel and is completed with a telescopic suction tube. Suitable for container sizes 60 and 205 litres, the innlet on the pump is 2" BSP and M59 x 5 male thread.

Features and Benefits

• Manufactured from steel for durability

• Zinc chrome finish protects against corrosion and wear and tear

• Can be used with both 60 and 205 litre containers making it a versatile product

• Is compatible with non-corrosive liquids and most lubricants

• Telescopic suction tube allows you to adjust the tube to suit your desired container

Typical Applications

• Automotive

• Engineering

Features and Benefits

• Manufactured from steel for durability

• Zinc chrome finish protects against corrosion and wear and tear

• Can be used with both 60 and 205 litre containers making it a versatile product

• Is compatible with non-corrosive liquids and most lubricants

• Telescopic suction tube allows you to adjust the tube to suit your desired container

Typical Applications

• Automotive

• Engineering

Download

Produk Lainnya

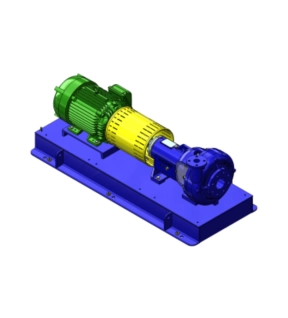

Discflo Horizontal Pumps

• No close tolerances

• Pulsation-free flow

• Laminar flow

• Non-impinging, preventing degradation

• Does not emulsify or damage delicate and shear sensitive products

• Includes in-line, close-coupled, side-by-side, over-under, and self-priming configurations

• Pulsation-free flow

• Laminar flow

• Non-impinging, preventing degradation

• Does not emulsify or damage delicate and shear sensitive products

• Includes in-line, close-coupled, side-by-side, over-under, and self-priming configurations

Kennedy Hydraulic Nipple, Straight, M8x1.25, Steel

Available in three sizes, these metric straight type hydraulic grease nipples are suited for use with Kennedy® grease guns and all other hydraulic grease equipment.

Features and Benefits

• Manufactured from steel for durability

• Available in three varying sizes to suit your specific applications

Typical Applications

• Engineering

• Fluid Handling

• Automotive

Features and Benefits

• Manufactured from steel for durability

• Available in three varying sizes to suit your specific applications

Typical Applications

• Engineering

• Fluid Handling

• Automotive

Kennedy Side Lever Grease Gun, 500cc, Bulk/Cartridge/Suction Fill, 4500psi

These side lever grip grease guns are ideal for professional, extended use, with a sturdy chrome-plated steel body. They can be used with medium/heavy greases. The working pressure is 4500 psi/310 bar.

Features & Benefits

• Chrome-plated steel body provides long lasting durability

• Side grip and offset nozzle allows precision on application

• Cartridge, bulk or suction fill allows for flexibility on refills

Typical Applications

• Applying lubricant to mechanical components

Notes

• Only LG400 has a rubber grip on the handle

Features & Benefits

• Chrome-plated steel body provides long lasting durability

• Side grip and offset nozzle allows precision on application

• Cartridge, bulk or suction fill allows for flexibility on refills

Typical Applications

• Applying lubricant to mechanical components

Notes

• Only LG400 has a rubber grip on the handle

Discflo Glass Lined Pumps

Glass lining is a proven technique for adding a super-durable, smooth, non-stick surface to metal equipment and components.

Discflo glass lined pumps use the dual-coat glass-lining process developed by Vitco, of PA. The glass lining is a mix of fine borosilicate glass, water, and clay, applied to the base metal substrate at high temperature. Vitco’s dual-coat process allows for extra durability and longevity as the base coat forms a strong bond with the base metal and the cover coat provides the non-stick characteristics.

Discflo glass lined pumps use the dual-coat glass-lining process developed by Vitco, of PA. The glass lining is a mix of fine borosilicate glass, water, and clay, applied to the base metal substrate at high temperature. Vitco’s dual-coat process allows for extra durability and longevity as the base coat forms a strong bond with the base metal and the cover coat provides the non-stick characteristics.