Pneumatic Tools

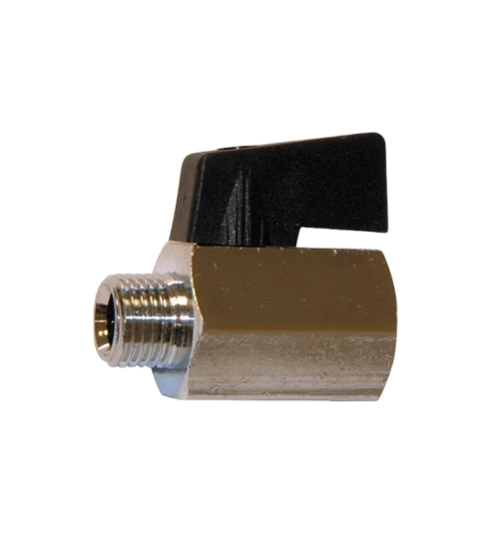

Kennedy VAB3FM 1/4 TURN BALL VALVE G3/8-G3/8 F-M

Available in Female to Male and Female to Female fitting.

Pressure range: 0 to +10bar.

Temperature range: -25 to +90°C.

Pressure range: 0 to +10bar.

Temperature range: -25 to +90°C.

Download

Produk Lainnya

Kennedy KR10S-6 KEN-FIT REDUCER 1 0mm STEM-6mm

Stem Reducers

Quick and simple tube insertion. Compact lightweight design with a well proven tube retaining system. Tapered threads have a re-usable thread seal and parallel threads have a rubber washer. Main body manufactured from nickel plated brass, acetal resin, PBT with a stainless steel retaining ring, nitrile tube seal and acetal resin tube release collar.

Pressure range: -0.9bar min to +10bar max. Temp range: -20°C min to +70°C max. Tube suitability: Nylon, polyurethane.

Quick and simple tube insertion. Compact lightweight design with a well proven tube retaining system. Tapered threads have a re-usable thread seal and parallel threads have a rubber washer. Main body manufactured from nickel plated brass, acetal resin, PBT with a stainless steel retaining ring, nitrile tube seal and acetal resin tube release collar.

Pressure range: -0.9bar min to +10bar max. Temp range: -20°C min to +70°C max. Tube suitability: Nylon, polyurethane.

Kennedy KTB4-1MT KEN-FIT BR/TEE 4 mm - G1/8 M/T

Branch Tee to Male Taper

Quick and simple tube insertion. Compact lightweight design with a well proven tube retaining system. Tapered threads have a re-usable thread seal and parallel threads have a rubber washer. Main body manufactured from nickel plated brass, acetal resin, PBT with a stainless steel retaining ring, nitrile tube seal and acetal resin tube release collar.

Pressure range: -0.9bar min to +10bar max. Temp range: -20°C min to +70°C max. Tube suitability: Nylon, polyurethane.

Quick and simple tube insertion. Compact lightweight design with a well proven tube retaining system. Tapered threads have a re-usable thread seal and parallel threads have a rubber washer. Main body manufactured from nickel plated brass, acetal resin, PBT with a stainless steel retaining ring, nitrile tube seal and acetal resin tube release collar.

Pressure range: -0.9bar min to +10bar max. Temp range: -20°C min to +70°C max. Tube suitability: Nylon, polyurethane.

Kennedy KEC10-2MP KEN-FIT E/CONN10mm - G1/4 M/P

Elbow Connector to Male Parallel

Quick and simple tube insertion. Compact lightweight design with a well proven tube retaining system. Tapered threads have a re-usable thread seal and parallel threads have a rubber washer. Main body manufactured from nickel plated brass, acetal resin, PBT with a stainless steel retaining ring, nitrile tube seal and acetal resin tube release collar.

Pressure range: -0.9bar min to +10bar max. Temp range: -20°C min to +70°C max. Tube suitability: Nylon, polyurethane.

Quick and simple tube insertion. Compact lightweight design with a well proven tube retaining system. Tapered threads have a re-usable thread seal and parallel threads have a rubber washer. Main body manufactured from nickel plated brass, acetal resin, PBT with a stainless steel retaining ring, nitrile tube seal and acetal resin tube release collar.

Pressure range: -0.9bar min to +10bar max. Temp range: -20°C min to +70°C max. Tube suitability: Nylon, polyurethane.

Chicago Pneumatic CP7731/CP7732 Series - Impact Wrenches

This impact wrench, designed to be the best tool for general maintenance with its torque of 450 ft.lbs / 610 Nm and its compactness of 4.4" / 112 mm, is highly recommended. Its jumbo hammer impact mechanism and metal housing offer high durability. The CP7731/CP7732 series is composed of 2 models: 3/8" short anvil and 1/2" short anvil.