Tools & Chemicals

Fluke Insulated Phillips screwdriver

- Phillips Screwdriver: two sizes available, sold individually

- Certified to 1000 V AC, 1500 V DC

- Ergonomic handle causes less strain, provides maximum torque

- Certified to 1000 V AC, 1500 V DC

- Ergonomic handle causes less strain, provides maximum torque

Download

Products Lainnya

Kennedy Retractable, Trimming Knife, Steel Blade

Suited for both left and right handed users, this retractable safety knife is ideal for regualr use. Supplied with five heavy duty carbon steel blades that can be stored in the body of the knife, the slimline, diecast body has a contoured grip which provides a greater degree of control and comfort. Finished with a handy lanyard hole at the base of the knife.

Features and Benefits

• Possesses extra storage in the body for up to five blades

• Slimline design allows you to cut in confined spaces

• Contoured, ergonomic design increases user comfort and grip

• Boasts a high quality carbon steel blade that holds a good cutting edge even with extensive use

• Retractable feature ensures safety and reduces the risk of accidental cutting

Typical Applications

• Construction

• Carpentry

• Electrical

• Plumbing

• Warehousing

• Retail

• Production Line

Warnings

• This product is only available to buy for over 18's

Features and Benefits

• Possesses extra storage in the body for up to five blades

• Slimline design allows you to cut in confined spaces

• Contoured, ergonomic design increases user comfort and grip

• Boasts a high quality carbon steel blade that holds a good cutting edge even with extensive use

• Retractable feature ensures safety and reduces the risk of accidental cutting

Typical Applications

• Construction

• Carpentry

• Electrical

• Plumbing

• Warehousing

• Retail

• Production Line

Warnings

• This product is only available to buy for over 18's

Kennedy-Pro Single End, Ratcheting Combination Spanner, 17mm, Metric

This range of bi-hexagonal ring ratchet spanners are a staple of any complete toolbox. Manufactured from chrome vanadium steel with a mirror polish finish, making for easier cleaning and preventing rust. The 72-teeth ratcheting system needs only 5° movement to operate the ratchet, making it ideal even in tight spots. Complete with a thin wall design to further allow access into confined areas. Available to purchase in various sizes to allow you to select the product that best suits your needs.

Features and Benefits

• Manufactured from vanadium steel for durability and overall product longevity

• Chrome plated mirror finish prevents dirt and oil attracting to the spanner

• Ratcheting system requires only 5° movement to operate for use even in confined spaces or awkward angles

• Thin wall design allows for greater access to hard to reach areas

Typical Applications

• Ideal for use by professionals such as mechanics, plumbers, engineers, electricians, general handiworkers and DIY enthusiasts

Standards

• Conforms to ASME B107.6

Features and Benefits

• Manufactured from vanadium steel for durability and overall product longevity

• Chrome plated mirror finish prevents dirt and oil attracting to the spanner

• Ratcheting system requires only 5° movement to operate for use even in confined spaces or awkward angles

• Thin wall design allows for greater access to hard to reach areas

Typical Applications

• Ideal for use by professionals such as mechanics, plumbers, engineers, electricians, general handiworkers and DIY enthusiasts

Standards

• Conforms to ASME B107.6

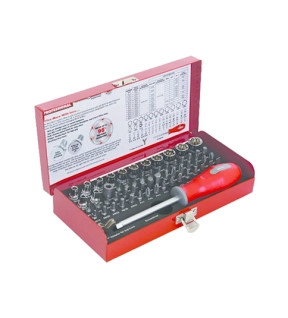

Kengrip 60 Piece Torq Set Screwdriver Bit Se

Featuring Ken-Grip® patented design sockets that grip fasteners that up to 95% rounded off and will not damage worn or rusted fasteners. Manufactured from Chrome Vanadium steel, they will fit a range of non-metric hexagons and E-Torx drive sizes. The screwdriver bits are manufactured from Chrome Molybdenum. Supplied in a robust case.

Features and Benefits

• Ken-Grip® sockets will not round off existing nuts

• 60 piece set is extremely comprehensive to ensure you have the correct component and tool to hand no matter the application

• Screwdriver bits are manufactured from chrome molybdenum steel, whilst the sockets are manufactured from chrome vanadium steel for optimum durability

• Supplied in a robust plastic case for ease of transportation, organisation and storage of your components

Contents

• Metric sockets: 4mm, 4.5mm, 5mm, 5.5mm, 6mm, 7mm, 8mm, 10mm, 11mm, 12mm, 13mm. 14mm

• Crosspoint: No 1, No 2, No 3

• Pozidriv: No 1, No 2, No 3

• Torx: T5, T6, T7, T8, T9, T10, T15, T20, T25, T27, T30, T40

• Slotted: 3.5, 4.5, 5.5, 6.5, 8

• Hexagon: 1.5, 2, 2.5, 3, 4, 5, 6, 7, 8

• Tri-Wing: No 3, No 4, No 5

• Torq Set: TS.5, TS.6, TS.8, TS.10

• SIT: No 10, No 20, No 25, No 30, No 40

• Accessories: 1/4in. Square drive, 1/4in. hex magnetic bit holder, Y adaptor for cup hook, Spinner handle

Typical Applications

• Construction

• Engineering

• Automotive

Features and Benefits

• Ken-Grip® sockets will not round off existing nuts

• 60 piece set is extremely comprehensive to ensure you have the correct component and tool to hand no matter the application

• Screwdriver bits are manufactured from chrome molybdenum steel, whilst the sockets are manufactured from chrome vanadium steel for optimum durability

• Supplied in a robust plastic case for ease of transportation, organisation and storage of your components

Contents

• Metric sockets: 4mm, 4.5mm, 5mm, 5.5mm, 6mm, 7mm, 8mm, 10mm, 11mm, 12mm, 13mm. 14mm

• Crosspoint: No 1, No 2, No 3

• Pozidriv: No 1, No 2, No 3

• Torx: T5, T6, T7, T8, T9, T10, T15, T20, T25, T27, T30, T40

• Slotted: 3.5, 4.5, 5.5, 6.5, 8

• Hexagon: 1.5, 2, 2.5, 3, 4, 5, 6, 7, 8

• Tri-Wing: No 3, No 4, No 5

• Torq Set: TS.5, TS.6, TS.8, TS.10

• SIT: No 10, No 20, No 25, No 30, No 40

• Accessories: 1/4in. Square drive, 1/4in. hex magnetic bit holder, Y adaptor for cup hook, Spinner handle

Typical Applications

• Construction

• Engineering

• Automotive

Kennedy-Pro 250mm (10'') 4 Piece Second Cut Engineers File Set With Handles

Set of 4 engineer's files fitted with ergonomically designed handles for a comfortable improved grip. Files are manufactured from T12 carbon steel, hardened and tempered to ensure a long lasting tool. Supplied in a woven wallet for easy storage.

Standards Met

• Manufactured to BS498:1990 and American Federal Standard GGG-F325B.

Features and Benefits

• Ergonomic grip with anti-slip finger placement pads ensures the tool stays tight and comfortable in your hand

• Lanyard hole in handle for extra protection when working at height

• Second cut teeth for quick and efficient removal of moderate material

• Woven wallet designed for easy removal and storage

Notes

• Sets available in 6"" (150mm), 8" (200mm) and 10" (250mm) versions

• Set contains Hand, Flat, Round and Half Round second engineer's files

Standards Met

• Manufactured to BS498:1990 and American Federal Standard GGG-F325B.

Features and Benefits

• Ergonomic grip with anti-slip finger placement pads ensures the tool stays tight and comfortable in your hand

• Lanyard hole in handle for extra protection when working at height

• Second cut teeth for quick and efficient removal of moderate material

• Woven wallet designed for easy removal and storage

Notes

• Sets available in 6"" (150mm), 8" (200mm) and 10" (250mm) versions

• Set contains Hand, Flat, Round and Half Round second engineer's files