Measuring Tools

Fluke T6-600 Electrical Tester

• Measure AC voltage and current without touching a live wire

• Troubleshoot with all power supply measurements at-a-glance

• See AC voltage and current values without test leads

• Troubleshoot with all power supply measurements at-a-glance

• See AC voltage and current values without test leads

Download

Products Lainnya

Fluke 190-504-III Color ScopeMeter, 500 MHz, 4 channels

Fluke 190-504-III Offers

Accurate and versatile, this portable oscilloscope provides a fast sampling rate of up to 5 GS/s, a 200 ps resolution, and deep memory of 10,000 samples per channel. Perform timing or amplitude-related measurements on three phases or three-axis control systems, or compare and contrast multiple test points in a circuit under test

- Up to four independent floating isolated inputs, up to 1000 V

- Up to 5 GS/s real time sampling (depending on model and channels used)

- Deep memory: 10,000 points per trace waveform capture (scope mode)

- CAT III 1000 V/CAT IV 600 V safety rated instrument for industrial environments

- Up to seven hours of battery operation using BP291

- Large, bright color display is easy to view in nearly any environment

- Easy to store and view historical data and transfer to a PC via USB or Wifi

- Convenient battery access door for quick battery swaps in the field

- IP51 rating, dust and drip-proof

- Connect-and-View triggering for intelligent, automatic triggering on fast, slow and even complex signals

- Frequency spectrum using FFT-analysis

- Automatic capture and REPLAY of 100 screens

- ScopeRecord mode gives 30,000 points per input channel for low frequency signal analysis

- TrendPlot Paperless Recorder mode with deep memory for longterm automatic measurements

- 5000 count DMM included in the 2-channel models

Applications

- Microelectronics

- Troubleshooting

Measure from mV to kV safely

Independently isolated inputs allow you to make measurements in mixed circuits having different ground references reducing the risk of accidental short circuits. Conventional bench oscilloscopes without special differential probes and isolation transformers can only reference measurements to line power earth ground. ScopeMeter 190 Series III test tools are engineered to cover a wide application range from mV to kV, so you’re ready for anything from microelectronics to heavy duty higher voltage electrical applications. 190 Series III 60 MHz and 100 MHz configurations include VPS421 100:1 probes for higher voltage applications, while the 200 MHz and 500 MHz configurations include VPS410-II 10:1 probes suitable for both microelectronics and higher voltage applications.

IP-51 rated for harsh environments

Rugged and shock-proof, ScopeMeter Test Tools are built for dirty, hazardous environments. With its sealed case, it can endure dust, drips, humidity and airborne pollutants. Every time you reach for ScopeMeter Test Tool you can be confident it will work reliably wherever your work takes you.

USB and Wi-Fi connectivity

The Fluke 190 Series III offers two USB ports, electrically isolated from measurement input circuits allowing you to quickly and easily transfer data to a PC, archive and share waveforms with OEMs, colleagues and support staff, or store waveforms, screen captures and instrument setups onto USB memory devices for later use. Easily transfer saved files via USB stick, direct connection via the USB interface or optional Wi-Fi connectivity. These files can be used for further data handling or in FlukeView-2 Software to study waveforms in greater detail.

Connect-and-View triggering

Connect-and-View triggering provides an instant, stable display without the need for adjusting settings. If you’ve used other scopes, you know how tricky triggering can be. If settings are incorrect, results can be unstable or incorrect. Connect-and-View automatically sets up correct triggering by recognizing signal patterns. Without touching a button, you get a stable, reliable and repeatable display of virtually any signal including motor drive and control signals. It’s especially fast and convenient when you’re measuring a number of test points in rapid succession.

Built-in digital multimeter

Conveniently switch from waveform analysis to precise multimeter measurements using the built in 5000 count digital multimeter on two channel 190 Series III models. Measurement functions include Vdc, Vac, Vac+dc, resistance, continuity and diode test. Measure current and temperature using suitable shunt, probe or adapter with wide range of scaling factors.

TrendPlot paperless recorder— records up to 11 days to help you find intermittent faults

The toughest faults to find are those that happen only once in a while. These intermittent events can be caused by bad connections, dust, dirt, corrosion, or simply broken wiring or connectors. Line outages, dips, swells and interruptions, or the starting and stopping of a motor can also cause a machine to stop. You may not be around when it happens, but the 190 Series III ScopeMeter Test Tool will be.

- Plot minimum and maximum peak values and average over time

- Plot any combination of up to four readings including voltages, amps, temperature, frequency and phase for all inputs, all with time and date stamp to pinpoint faults

Accurate and versatile, this portable oscilloscope provides a fast sampling rate of up to 5 GS/s, a 200 ps resolution, and deep memory of 10,000 samples per channel. Perform timing or amplitude-related measurements on three phases or three-axis control systems, or compare and contrast multiple test points in a circuit under test

- Up to four independent floating isolated inputs, up to 1000 V

- Up to 5 GS/s real time sampling (depending on model and channels used)

- Deep memory: 10,000 points per trace waveform capture (scope mode)

- CAT III 1000 V/CAT IV 600 V safety rated instrument for industrial environments

- Up to seven hours of battery operation using BP291

- Large, bright color display is easy to view in nearly any environment

- Easy to store and view historical data and transfer to a PC via USB or Wifi

- Convenient battery access door for quick battery swaps in the field

- IP51 rating, dust and drip-proof

- Connect-and-View triggering for intelligent, automatic triggering on fast, slow and even complex signals

- Frequency spectrum using FFT-analysis

- Automatic capture and REPLAY of 100 screens

- ScopeRecord mode gives 30,000 points per input channel for low frequency signal analysis

- TrendPlot Paperless Recorder mode with deep memory for longterm automatic measurements

- 5000 count DMM included in the 2-channel models

Applications

- Microelectronics

- Troubleshooting

Measure from mV to kV safely

Independently isolated inputs allow you to make measurements in mixed circuits having different ground references reducing the risk of accidental short circuits. Conventional bench oscilloscopes without special differential probes and isolation transformers can only reference measurements to line power earth ground. ScopeMeter 190 Series III test tools are engineered to cover a wide application range from mV to kV, so you’re ready for anything from microelectronics to heavy duty higher voltage electrical applications. 190 Series III 60 MHz and 100 MHz configurations include VPS421 100:1 probes for higher voltage applications, while the 200 MHz and 500 MHz configurations include VPS410-II 10:1 probes suitable for both microelectronics and higher voltage applications.

IP-51 rated for harsh environments

Rugged and shock-proof, ScopeMeter Test Tools are built for dirty, hazardous environments. With its sealed case, it can endure dust, drips, humidity and airborne pollutants. Every time you reach for ScopeMeter Test Tool you can be confident it will work reliably wherever your work takes you.

USB and Wi-Fi connectivity

The Fluke 190 Series III offers two USB ports, electrically isolated from measurement input circuits allowing you to quickly and easily transfer data to a PC, archive and share waveforms with OEMs, colleagues and support staff, or store waveforms, screen captures and instrument setups onto USB memory devices for later use. Easily transfer saved files via USB stick, direct connection via the USB interface or optional Wi-Fi connectivity. These files can be used for further data handling or in FlukeView-2 Software to study waveforms in greater detail.

Connect-and-View triggering

Connect-and-View triggering provides an instant, stable display without the need for adjusting settings. If you’ve used other scopes, you know how tricky triggering can be. If settings are incorrect, results can be unstable or incorrect. Connect-and-View automatically sets up correct triggering by recognizing signal patterns. Without touching a button, you get a stable, reliable and repeatable display of virtually any signal including motor drive and control signals. It’s especially fast and convenient when you’re measuring a number of test points in rapid succession.

Built-in digital multimeter

Conveniently switch from waveform analysis to precise multimeter measurements using the built in 5000 count digital multimeter on two channel 190 Series III models. Measurement functions include Vdc, Vac, Vac+dc, resistance, continuity and diode test. Measure current and temperature using suitable shunt, probe or adapter with wide range of scaling factors.

TrendPlot paperless recorder— records up to 11 days to help you find intermittent faults

The toughest faults to find are those that happen only once in a while. These intermittent events can be caused by bad connections, dust, dirt, corrosion, or simply broken wiring or connectors. Line outages, dips, swells and interruptions, or the starting and stopping of a motor can also cause a machine to stop. You may not be around when it happens, but the 190 Series III ScopeMeter Test Tool will be.

- Plot minimum and maximum peak values and average over time

- Plot any combination of up to four readings including voltages, amps, temperature, frequency and phase for all inputs, all with time and date stamp to pinpoint faults

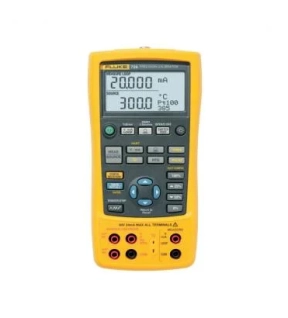

Fluke 726 Precision Multifunction Calibrators

Process calibration designed specifically for process industries

The Fluke 726 is a precise and powerful, yet easy-to-use, field calibrator. It features broad workload coverage, calibration power, and unsurpassed accuracy needed by process professionals. It measures and sources almost all process parameters to calibrate almost anything. Use it to test sensors and valves, and to test and calibrate transmitters. The 726 interprets results without the help of a calculator and stores measurement data for later analysis.

Measurement capabilities

This precision multifunction calibrator measures volts, mA, pressure, RTDs, thermocouples, frequency, and resistance to test sensors and transmitters. The 726 also sources and simulates volts, mA, thermocouples, RTDs, frequency to calibrate transmitters. Measures and/or sources pressure using when paired with any of the 50 Fluke 750P series Pressure Modules to test and calibrate pressure transmitters and other devices. The 726 can also:

- Source mA with simultaneous pressure measurement to conduct valve and I/P test

- Conduct enhanced flowmeter testing with frequency totalizer and frequency pulse train source mode

Designed for ease of use

The 726 has built-in features that make it easier to use in nearly any measurement situation. From its ability to store frequently used test setups, to programming custom RTD probe calibration constants for enhanced temperature measurement, or the integrated voltage input protection design that improves reliability, the 726 is built to perform. The use of two separate channels even allows you to measure, source, or view process signals simultaneously. The backlit display provides better visibility in low-light conditions, and the standard 3-year warranty provides extra confidence that the 726 will be there when you need it to be.

You can also use the 726 to:

- Capture the set, reset, and deadband of a pressure switch with the integrated switch test

- Calculate the transmitter error % to interpret calibration results without the use of a calculator

- Perform fast linearity tests with the auto-step and auto-ramp features

- Power a transmitter during test using 24 V loop supply and simultaneous mA measurement

The Fluke 726 is a precise and powerful, yet easy-to-use, field calibrator. It features broad workload coverage, calibration power, and unsurpassed accuracy needed by process professionals. It measures and sources almost all process parameters to calibrate almost anything. Use it to test sensors and valves, and to test and calibrate transmitters. The 726 interprets results without the help of a calculator and stores measurement data for later analysis.

Measurement capabilities

This precision multifunction calibrator measures volts, mA, pressure, RTDs, thermocouples, frequency, and resistance to test sensors and transmitters. The 726 also sources and simulates volts, mA, thermocouples, RTDs, frequency to calibrate transmitters. Measures and/or sources pressure using when paired with any of the 50 Fluke 750P series Pressure Modules to test and calibrate pressure transmitters and other devices. The 726 can also:

- Source mA with simultaneous pressure measurement to conduct valve and I/P test

- Conduct enhanced flowmeter testing with frequency totalizer and frequency pulse train source mode

Designed for ease of use

The 726 has built-in features that make it easier to use in nearly any measurement situation. From its ability to store frequently used test setups, to programming custom RTD probe calibration constants for enhanced temperature measurement, or the integrated voltage input protection design that improves reliability, the 726 is built to perform. The use of two separate channels even allows you to measure, source, or view process signals simultaneously. The backlit display provides better visibility in low-light conditions, and the standard 3-year warranty provides extra confidence that the 726 will be there when you need it to be.

You can also use the 726 to:

- Capture the set, reset, and deadband of a pressure switch with the integrated switch test

- Calculate the transmitter error % to interpret calibration results without the use of a calculator

- Perform fast linearity tests with the auto-step and auto-ramp features

- Power a transmitter during test using 24 V loop supply and simultaneous mA measurement

Fluke 190-104-III-S Color ScopeMeter with FlukeView-2 software package, 100 MHz, 4 channel

Fluke 190-104-III-S Offers

Accurate and versatile, this portable oscilloscope provides a fast sampling rate of up to 5 GS/s, a 200 ps resolution, and deep memory of 10,000 samples per channel. Perform timing or amplitude-related measurements on three phases or three-axis control systems, or compare and contrast multiple test points in a circuit under test.

- Up to four independent floating isolated inputs, up to 1000 V

- Up to 5 GS/s real time sampling (depending on model and channels used)

- Deep memory: 10,000 points per trace waveform capture (scope mode)

- CAT III 1000 V/CAT IV 600 V safety rated instrument for industrial environments

- Up to seven hours of battery operation using BP291

- Large, bright color display is easy to view in nearly any environment

- Easy to store and view historical data and transfer to a PC via USB or Wifi

- Convenient battery access door for quick battery swaps in the field

- IP51 rating, dust and drip-proof

- Connect-and-View triggering for intelligent, automatic triggering on fast, slow and even complex signals

- Frequency spectrum using FFT-analysis

- Automatic capture and REPLAY of 100 screens

- ScopeRecord mode gives 30,000 points per input channel for low frequency signal analysis

- TrendPlot Paperless Recorder mode with deep memory for longterm automatic measurements

- 5000 count DMM included in the 2-channel models

Applications

- Microelectronics

- Troubleshooting

Measure from mV to kV safely

Independently isolated inputs allow you to make measurements in mixed circuits having different ground references reducing the risk of accidental short circuits. Conventional bench oscilloscopes without special differential probes and isolation transformers can only reference measurements to line power earth ground. ScopeMeter 190 Series III test tools are engineered to cover a wide application range from mV to kV, so you’re ready for anything from microelectronics to heavy duty higher voltage electrical applications. 190 Series III 60 MHz and 100 MHz configurations include VPS421 100:1 probes for higher voltage applications, while the 200 MHz and 500 MHz configurations include VPS410-II 10:1 probes suitable for both microelectronics and higher voltage applications.

IP-51 rated for harsh environments

Rugged and shock-proof, ScopeMeter Test Tools are built for dirty, hazardous environments. With its sealed case, it can endure dust, drips, humidity and airborne pollutants. Every time you reach for ScopeMeter Test Tool you can be confident it will work reliably wherever your work takes you.

USB and Wi-Fi connectivity

The Fluke 190 Series III offers two USB ports, electrically isolated from measurement input circuits allowing you to quickly and easily transfer data to a PC, archive and share waveforms with OEMs, colleagues and support staff, or store waveforms, screen captures and instrument setups onto USB memory devices for later use. Easily transfer saved files via USB stick, direct connection via the USB interface or optional Wi-Fi connectivity. These files can be used for further data handling or in FlukeView-2 Software to study waveforms in greater detail.

Connect-and-View triggering

Connect-and-View triggering provides an instant, stable display without the need for adjusting settings. If you’ve used other scopes, you know how tricky triggering can be. If settings are incorrect, results can be unstable or incorrect. Connect-and-View automatically sets up correct triggering by recognizing signal patterns. Without touching a button, you get a stable, reliable and repeatable display of virtually any signal including motor drive and control signals. It’s especially fast and convenient when you’re measuring a number of test points in rapid succession.

Built-in digital multimeter

Conveniently switch from waveform analysis to precise multimeter measurements using the built in 5000 count digital multimeter on two channel 190 Series III models. Measurement functions include Vdc, Vac, Vac+dc, resistance, continuity and diode test. Measure current and temperature using suitable shunt, probe or adapter with wide range of scaling factors.

TrendPlot paperless recorder— records up to 11 days to help you find intermittent faults

The toughest faults to find are those that happen only once in a while. These intermittent events can be caused by bad connections, dust, dirt, corrosion, or simply broken wiring or connectors. Line outages, dips, swells and interruptions, or the starting and stopping of a motor can also cause a machine to stop. You may not be around when it happens, but the 190 Series III ScopeMeter Test Tool will be.

- Plot minimum and maximum peak values and average over time

- Plot any combination of up to four readings including voltages, amps, temperature, frequency and phase for all inputs, all with time and date stamp to pinpoint faults

Accurate and versatile, this portable oscilloscope provides a fast sampling rate of up to 5 GS/s, a 200 ps resolution, and deep memory of 10,000 samples per channel. Perform timing or amplitude-related measurements on three phases or three-axis control systems, or compare and contrast multiple test points in a circuit under test.

- Up to four independent floating isolated inputs, up to 1000 V

- Up to 5 GS/s real time sampling (depending on model and channels used)

- Deep memory: 10,000 points per trace waveform capture (scope mode)

- CAT III 1000 V/CAT IV 600 V safety rated instrument for industrial environments

- Up to seven hours of battery operation using BP291

- Large, bright color display is easy to view in nearly any environment

- Easy to store and view historical data and transfer to a PC via USB or Wifi

- Convenient battery access door for quick battery swaps in the field

- IP51 rating, dust and drip-proof

- Connect-and-View triggering for intelligent, automatic triggering on fast, slow and even complex signals

- Frequency spectrum using FFT-analysis

- Automatic capture and REPLAY of 100 screens

- ScopeRecord mode gives 30,000 points per input channel for low frequency signal analysis

- TrendPlot Paperless Recorder mode with deep memory for longterm automatic measurements

- 5000 count DMM included in the 2-channel models

Applications

- Microelectronics

- Troubleshooting

Measure from mV to kV safely

Independently isolated inputs allow you to make measurements in mixed circuits having different ground references reducing the risk of accidental short circuits. Conventional bench oscilloscopes without special differential probes and isolation transformers can only reference measurements to line power earth ground. ScopeMeter 190 Series III test tools are engineered to cover a wide application range from mV to kV, so you’re ready for anything from microelectronics to heavy duty higher voltage electrical applications. 190 Series III 60 MHz and 100 MHz configurations include VPS421 100:1 probes for higher voltage applications, while the 200 MHz and 500 MHz configurations include VPS410-II 10:1 probes suitable for both microelectronics and higher voltage applications.

IP-51 rated for harsh environments

Rugged and shock-proof, ScopeMeter Test Tools are built for dirty, hazardous environments. With its sealed case, it can endure dust, drips, humidity and airborne pollutants. Every time you reach for ScopeMeter Test Tool you can be confident it will work reliably wherever your work takes you.

USB and Wi-Fi connectivity

The Fluke 190 Series III offers two USB ports, electrically isolated from measurement input circuits allowing you to quickly and easily transfer data to a PC, archive and share waveforms with OEMs, colleagues and support staff, or store waveforms, screen captures and instrument setups onto USB memory devices for later use. Easily transfer saved files via USB stick, direct connection via the USB interface or optional Wi-Fi connectivity. These files can be used for further data handling or in FlukeView-2 Software to study waveforms in greater detail.

Connect-and-View triggering

Connect-and-View triggering provides an instant, stable display without the need for adjusting settings. If you’ve used other scopes, you know how tricky triggering can be. If settings are incorrect, results can be unstable or incorrect. Connect-and-View automatically sets up correct triggering by recognizing signal patterns. Without touching a button, you get a stable, reliable and repeatable display of virtually any signal including motor drive and control signals. It’s especially fast and convenient when you’re measuring a number of test points in rapid succession.

Built-in digital multimeter

Conveniently switch from waveform analysis to precise multimeter measurements using the built in 5000 count digital multimeter on two channel 190 Series III models. Measurement functions include Vdc, Vac, Vac+dc, resistance, continuity and diode test. Measure current and temperature using suitable shunt, probe or adapter with wide range of scaling factors.

TrendPlot paperless recorder— records up to 11 days to help you find intermittent faults

The toughest faults to find are those that happen only once in a while. These intermittent events can be caused by bad connections, dust, dirt, corrosion, or simply broken wiring or connectors. Line outages, dips, swells and interruptions, or the starting and stopping of a motor can also cause a machine to stop. You may not be around when it happens, but the 190 Series III ScopeMeter Test Tool will be.

- Plot minimum and maximum peak values and average over time

- Plot any combination of up to four readings including voltages, amps, temperature, frequency and phase for all inputs, all with time and date stamp to pinpoint faults

Kennedy 150mm/6" FLEXIBLE RUSTLES S RULE ROUND END

The range of Kennedy round end engineers rulers are made from spring tempered flexible steel blades with permanent black figures and graduations. With rustless properties and 12mm blade width and and a satin chrome anti-glare finish they are extremly easy to read with EEC Class one accuracy (/- 0.2mm full scale). Features a handy hanging hole for easy storage.

Features and Benefits

• Spring tempered flexible steel blades with round end

• Anti-glare properties

• With hanging hole for easy storage

• Permanent black figures and graduations

• ECC Class one accuracy

Typical Applications

• Measurements

• Engineering

• Industrial

• Workshop

• On site

Notes

• Available in imperial and metric measurements

Features and Benefits

• Spring tempered flexible steel blades with round end

• Anti-glare properties

• With hanging hole for easy storage

• Permanent black figures and graduations

• ECC Class one accuracy

Typical Applications

• Measurements

• Engineering

• Industrial

• Workshop

• On site

Notes

• Available in imperial and metric measurements