Abrasive

3M Coated Sheet, 230 x 280mm, Aluminium Oxide, P80

314D 230 x 280mm (9"x11") Sheets.

Aluminum oxide abrasive product rolls and sheets constructed on a J weight, durable cloth backing. For use in metalworking.

Features and Benefits

• Perfect for finishing, contouring, deburring and removing rust

• Versatile, durable sheet performs excellently on metal, wood and plastic surfaces

• Cloth backing is both flexible and durable enough for machine use

• Tear sheets by hand for convenient sizing and reduced waste

Aluminum oxide abrasive product rolls and sheets constructed on a J weight, durable cloth backing. For use in metalworking.

Features and Benefits

• Perfect for finishing, contouring, deburring and removing rust

• Versatile, durable sheet performs excellently on metal, wood and plastic surfaces

• Cloth backing is both flexible and durable enough for machine use

• Tear sheets by hand for convenient sizing and reduced waste

Download

Products Lainnya

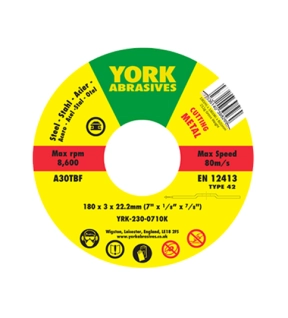

York Cutting Disc, 30-Medium/Coarse, 180 x 3 x 22.23 mm, Type 42, Aluminium Oxide

Manufactured to assure operator safety and optimum performance.

Grade A30 - For general-purpose use on metals.

Features and Benefits

• Cuts very cleanly, with minimal burrs

• Excels at cutting quickly through metal pipes, tubes, flat sheets and more

• Incredibly durable for long-lasting performance

Notes

• Cutting discs must never be used for grinding and must always be presented to the work piece at an angle of 90°.

• For use with all appropriate handheld angle grinders.

Grade A30 - For general-purpose use on metals.

Features and Benefits

• Cuts very cleanly, with minimal burrs

• Excels at cutting quickly through metal pipes, tubes, flat sheets and more

• Incredibly durable for long-lasting performance

Notes

• Cutting discs must never be used for grinding and must always be presented to the work piece at an angle of 90°.

• For use with all appropriate handheld angle grinders.

Kennedy B44 MOUNTED POINT

'B' Shape - Shank Diameter 3mm

Features and Benefits

• All points are aluminium oxide with 'rubenite™' as standard for all general-purpose grinding and deburring on steels and most metals

• Durable and reliable constrution

Typical Applications

• Suitable for portable die and straight hand grinders

Notes

• Shank diameters are metric as listed below with inch sizes available on request

• Maximum speeds are quoted assuming that collet to back of point does not exceed 12.7mm (1/2") and are for guidance only

Features and Benefits

• All points are aluminium oxide with 'rubenite™' as standard for all general-purpose grinding and deburring on steels and most metals

• Durable and reliable constrution

Typical Applications

• Suitable for portable die and straight hand grinders

Notes

• Shank diameters are metric as listed below with inch sizes available on request

• Maximum speeds are quoted assuming that collet to back of point does not exceed 12.7mm (1/2") and are for guidance only

York 30mm Crimped Wire Flat End De-carbonising Brush - 30SWG

Crimped wire flat end de-carbonising brushes are designed for hard to reach areas such as drilled holes, recesses and corners. These wire brushes removes of burrs, rust and paint.

Features and Benefits

• Very flexible in use to get into those hard to reach places

Features and Benefits

• Very flexible in use to get into those hard to reach places

Cotswold 3-ROW PLASTIC HANDLE WIRE SCRATCH BRUSH

Wire scratch brushes designed to remove stubborn deposits.

Features and Benefits

• Cast steel bristles to remove paint, rust, dirt and stubborn deposits

• Plastic ergonomical handle design for hand comfort

• Hole on the end of the handle for easy storage

Notes

COT9066500K - Includes a scraper

Features and Benefits

• Cast steel bristles to remove paint, rust, dirt and stubborn deposits

• Plastic ergonomical handle design for hand comfort

• Hole on the end of the handle for easy storage

Notes

COT9066500K - Includes a scraper